With the power of artificial intelligence (AI), the oil and gas industry can work smarter, not harder.

Over the years, AI and machine learning (ML) have helped the industry increase production, drive costs down, improve safety and speed up workflows. Gone are the days of upstream companies merely curious about how they can use AI. Now E&Ps are finding ways to actively apply it at scale and make a meaningful difference to their bottom lines.

Bill Braun, CIO for Chevron, said the company aims to apply AI and ML technologies to both its traditional and low-carbon businesses. Chevron employs more than 300 data scientists and has trained more than 1,000 employees in data science.

Over the years, Chevron has deployed hundreds of AI solutions, including a patch that employees can wear to monitor their sweat for signs of dehydration and heat distress. The company uses AI to pick up on the differences between people and the environments in which they operate. AI is also used to filter out background noise so that personnel can speak more easily in noisy environments.

“We're deploying hard hats that have integrated AI systems that actually have a noise reduction system that takes out the background noise in industrial environments. This enables our employees to more easily talk to each other at facilities without having to adjust or remove any of their PPE [personal protective equipment],” Braun said.

Computer vision, which relies on AI technology, can help detect sensitive vegetation or habitats for protected species to help inform Chevron’s pad site design with minimal environmental disturbance, he said.

For the supermajor’s lower carbon business, Chevron is using AI to help determine the right reservoir characteristics for carbon sequestration.

“We don't have the history like we do in our traditional business in terms of what reservoir characteristics are most desirable for us to be looking for in the places where we deposit carbon as we take it out of the atmosphere,” he said.

Chevron’s AI teams are working with geologists and petrophysicists to model and simulate those reservoirs using synthetic data.

“They're imagining a world where we've been in that business for 20 or 30 years to simulate how carbon would move through that reservoir to help us understand what the dynamics will be and what makes a more successful or less successful reservoir to make sure it stays there locked in the earth,” Braun said.

Moe Tanabian, chief product officer at Cognite, calls AI a prediction machine.

“The earliest and easiest machine learning models that we used in oil and gas were around making sure we could predict a machine failure before it happens,” he said. “Predictive maintenance has been a major focus area for most industries, particularly oil and gas, because assets are very expensive.”

AI looks at past data to determine causes of failures and the likelihood of failures in the future. Armed with that information, it’s possible to plan corrective maintenance, which is less costly and has less impact on production yield.

Eliminating the grunt work

James Brady, chief digital officer for Baker Hughes oilfield services and equipment, said the use of AI in the industry has evolved. Early in, ML was used for facies classification in well logs and for processing seismic data. Later, the industry started using pattern recognition on production data and for simulations and started building digital twins.

One of the current AI projects Baker Hughes is focused on is Leucipa, which combines Amazon Web Services cloud capabilities with Baker Hughes’ oil and gas expertise in a product that the companies say will help operators optimize production of oil and gas fields.

Sriram Srinivasan, senior vice president for Halliburton Global Technology, said the service company is using AI and ML to automate assessments of drill bits.

“Historically, the approach involved the use of human beings looking at these bits that are worn and deciding which ones have to be replaced or which ones need to be repaired,” he said. “It accelerates this process and now you get more consistency because human beings are not machines. There's a lot of variability from person to person.”

Halliburton’s Landmark business is using AI, ML and neural networks to help with routine seismic data interpretation, saving the “hard interpretations for the human beings,” he said. “We don't remove the people out entirely as yet, but we use this in an assist fashion.”

SparkCognition CTO Sridhar Sudarsan said using AI can drastically decrease the amount of time required for seismic imaging.

“It's all about faster, better, cheaper when it comes to exploration. This is faster and cheaper, without compromising on the quality of the results,” he said.

The company has collaborated with Shell on a generative AI project using deep learning to generate subsurface images using far fewer seismic shots than traditionally necessary while preserving subsurface image quality.

Bluware CEO Dan Piette said geoscientists using AI-based tools like InteractivAI are able to perform tasks in hours that used to take geophysicists months. InteractivAI uses deep learning algorithms to seek out turbidites, faults, horizons and salt.

“Artificial intelligence is not going to replace geophysicists, but geophysicists who use artificial intelligence are going to replace” the ones who don’t, he said. “It's a lever, it's a magnifying glass. It's just another tool. People in this industry should not be afraid of it because all it does is it makes them smarter, even if they disagree with it.”

At its heart, the technology “eliminates the grunt work” from interpretation, he said.

“Every geoscientist, whether they know it or not, they're creating a story,” Piette said. “They're telling a real story about what happened to that molecule from the time it was a frond on a leaf in the Carboniferous era … to the time it gets pumped out as oil.”

Jay Shah, principal of energy marketing and innovation programs, AWS, said the use of AI and ML have helped CNX Resources do something that “everyone thinks is diametrically opposed,” which is to increase natural gas production by 4% while lowering emissions by 48%. In that project, CNX Resources, an AWS customer, worked with Ambynt, a partner of AWS, to optimize plunger lift.

Exxon Mobil, another AWS customer, is working with Scepter, Inc. to monitor emissions, a process that is gathering vast amounts of data from multiple sources. All that data is integrated and analyzed through a data fusion platform developed by Scepter, and AWS cloud services are aggregating and analyzing the data to pinpoint emissions events.

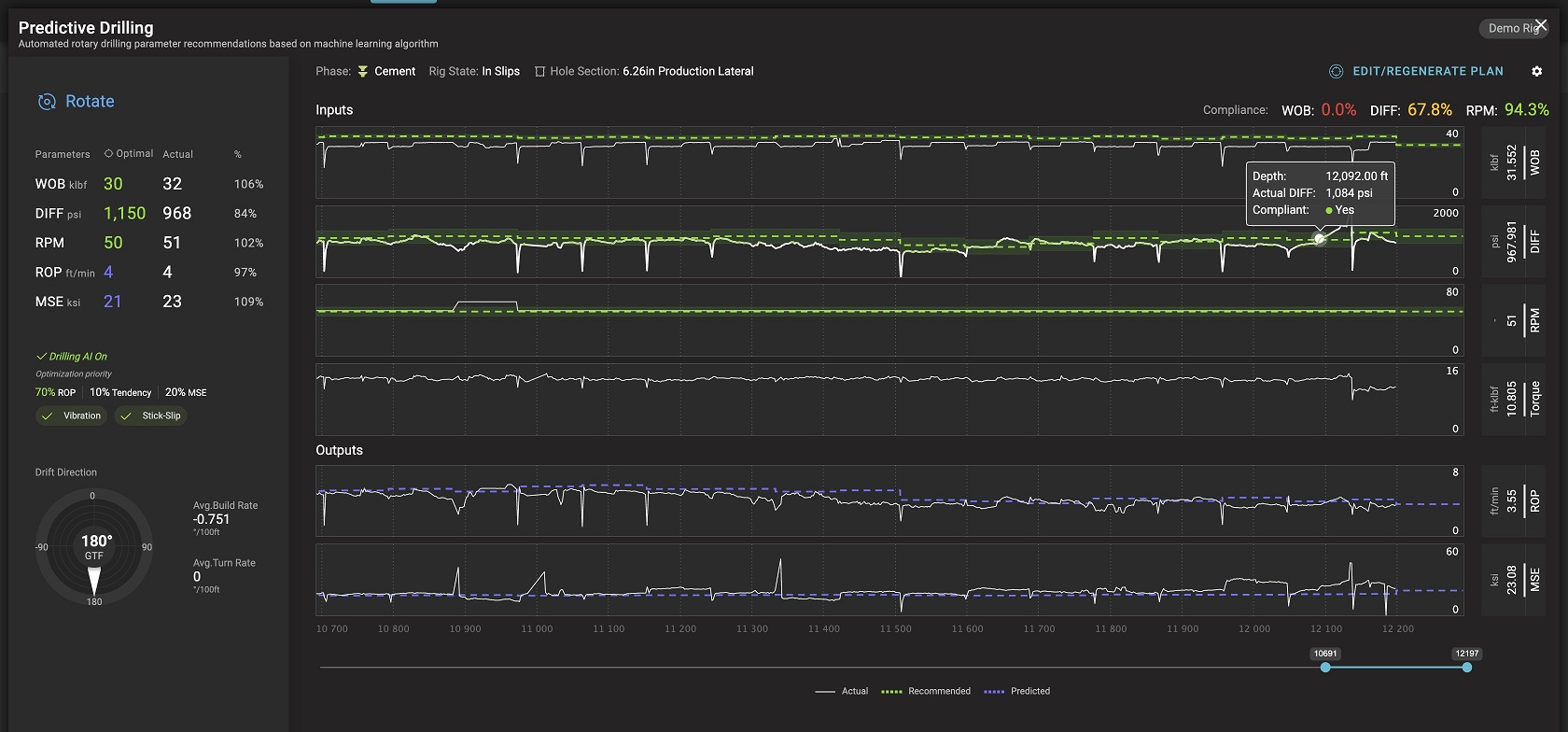

Kriti Singh, senior research data scientist at Corva and lead developer of the company’s predictive drilling product, said Corva has drawn heavily on AI and ML to develop its predictive drilling product, which Nabors has been using with multiple operators since August.

A perfect match

Initially, the drilling product was designed to make recommendations, she said.

“But that does not help much because they still have to pay attention to our advisory software. They would have to look at one dashboard and they have to manually enter that data,” she said.

Corva realized the next step was automation, which is offered in the company’s predictive drilling product.

“The main advantage is it really frees up the driller from the need to look at the data constantly,” she said.

The system provides main set points for controllable drilling parameters like ROP, rotations per minute, differential pressure and weight on bit while the algorithm runs in the background, optimizing for real-time drilling conditions, Singh said.

In early September, Nabors announced a Delaware Basin operator had deployed a combination of rotary steerable, predictive drilling and Nabors SmartROS on four wells, which increased the average ROP by 36% and decreased average vibration by 9.7%. By the fourth well, the crew had increased the use of predictive drilling to more than 80% of the lateral.

From object identification to decision making based on AI guidance to managing fleets, AI is making a big difference in subsea robotics, Nikunjkumar Patel, vice president of engineering and technology at Oceaneering, said.

AI is also critical for subsea inspection seeking out corrosion, cracking and leaks.

“We are investing heavily in that area,” he said.

Mehdi Miremadi, a senior partner at McKinsey & Co., said one of the main pushes in AI has been around creating digital twins, which enables the use of data to better detect patterns, such as in seismic or formation data.

“The value that players get out of it is that you can improve the hit rates significantly through the advanced analytics. You can reduce the time of exploration,” he said. “The aspiration is moving it from years to weeks.”

Song Hou, who heads up CGG’s AI lab, said much of the industry’s data is “a perfect match” for AI, as the vast volumes of seismic data have been problematic for humans to analyze. AI helps both with efficiency and in improving the ultimate seismic product, he said.

Previously, geologists might take months to interpret seismic data, and results varied because people interpreted the data differently, he said. With AI, there is more consistency and the results are faster, he said.

Rise of machine tutors

Manas Dutta, general manager for the Workforce Excellence Break Through Initiative portfolio at Honeywell Process Solutions, said the company uses AI for virtual reality-based training. The company’s IFS simulator can help people “skill up faster,” he said. He expects AI and generative AI to help drive down the costs of using VR for training and for the industry’s acceptance of VR training to increase.

AI can also help with human reliability, he said.

“When we talk about reliability in general, process and asset reliability, everybody understands, but most of the time though, the piece that is ignored is human reliability. How we can really improve human reliability in the oil and gas industry is equally important,” Dutta said.

Different people running an asset may respond to abnormal situations differently in their effort to bring the systems back to normal.

According to Dutta, Honeywell’s HALO Operator Advisor solution uses AI to objectively analyze process and event data, benchmark the best practices based on past records and provide actionable recommendations to reduce operations variability and improve operators’ efficiency.

Shinydocs uses AI to classify content for records management, which helps with producing the right information at the right time, Jason Cassidy, company founder and CEO, said. The system was used to help a natural gas company locate drawings related to pressure tests after it bought another company that had experienced an explosion.

“We needed to find every pressure test across every document across a billion documents,” he said, because doing so could help save lives.

Shinydocs taught the AI what a pressure test looks like and gave it instructions on how to find it across file shares, SharePoints and other systems.

“We came back and said, ‘across your terabytes of information, across your hundreds of millions of files, here's where every pressure test is,’” he said.

That knowledge, he said, allowed the company to go from not knowing where things were to having certainty about every pressure test so it could avoid a catastrophic failure.

“The AI that we've been using for the last 15 years is actually pretty darn good, and we can make it even better by understanding our data better,” Cassidy said.

Future AI

Halliburton’s Srinivasan said there is no question AI technologies offer huge potential to the industry.

“We have to proceed with care and caution like we would with any other technology,” he said.

SparkCognition’s Sudarsan said the use of AI is growing rapidly in both exploration and production spaces.

“We've evolved significantly from the question about ‘What can AI do to help me in my processes’ to more about ‘How do I get the most benefit of AI at scale?’” he said. “That, to me, is a pivotal change.”

Editor’s note: This is the second part of a multi-part series examining the use of artificial intelligence in the oil patch. Read part one here.

Recommended Reading

TechnipFMC Eyes $30B in Subsea Orders by 2025

2024-02-23 - TechnipFMC is capitalizing on an industry shift in spending to offshore projects from land projects.

E&P Earnings Season Proves Up Stronger Efficiencies, Profits

2024-04-04 - The 2024 outlook for E&Ps largely surprises to the upside with conservative budgets and steady volumes.

Patterson-UTI Braces for Activity ‘Pause’ After E&P Consolidations

2024-02-19 - Patterson-UTI saw net income rebound from 2022 and CEO Andy Hendricks says the company is well positioned following a wave of E&P consolidations that may slow activity.

Why Endeavor Energy's Founder Sold His Company After Years of Rebuffing Offers

2024-02-13 - Autry Stephens', the 85-year-old wildcatter, decision to sell came after he was diagnosed with cancer, according to three people who discussed his health with him.

Baker Hughes Awarded Saudi Pipeline Technology Contract

2024-04-23 - Baker Hughes will supply centrifugal compressors for Saudi Arabia’s new pipeline system, which aims to increase gas distribution across the kingdom and reduce carbon emissions