Presented by:

Editor's note: This article appears in the new E&P newsletter. Subscribe to the E&P newsletter here.

Perforation efficiency is defined as the percentage of perforations that take treatment fluid during fracturing operations. Typically, this would be in the range of 60% to 70%. To improve perforation efficiency, modern well designs increasingly call for limited-entry perforating techniques and single-shot perforating systems that deliver larger and more consistent entry hole diameters. The goal is to ensure more uniform distribution of frac fluid in each cluster to develop more uniform frac wings, maximize stimulated rock volume, placed sand and ultimately boost well productivity.

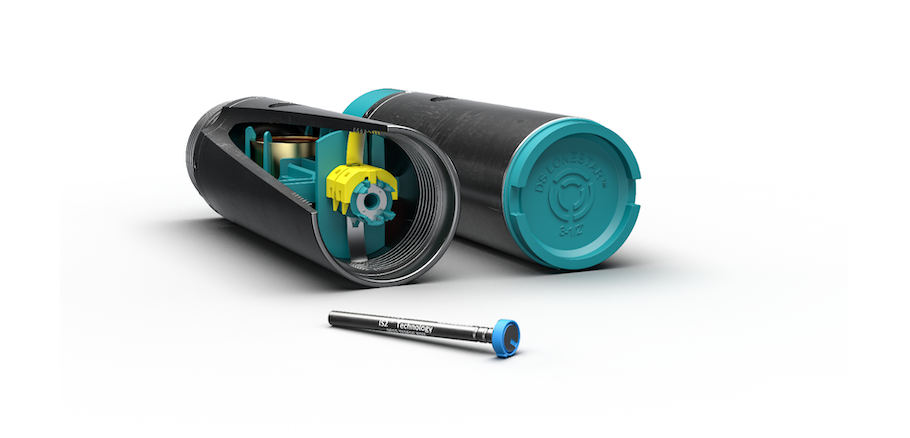

DynaEnergetics’ DS LoneStar provides engineers with a single-shot perforating system with near-perfect perforation efficiency.

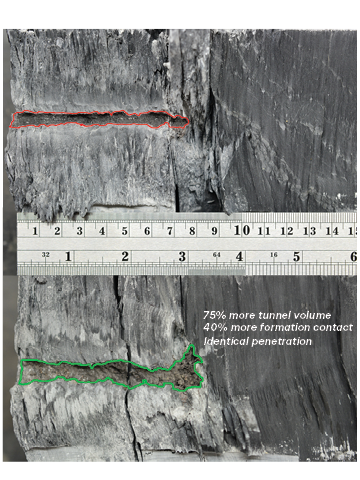

Bottom: The DS LoneStar DP40 was tested under Section II criteria and shot in real 18k UCS shale core under 3,000 psi wellbore pressure.

An in-plane, single-shot perforating system equipped with a variety of LoneStar formation-tuned shaped charges delivers extreme reservoir contact and near 100% cluster efficiency. Available in both externally oriented and standard models, it delivers large, ultra-consistent entry hole diameters that enable greater area open to flow and greatly increased formation contact area. Its sub-less, unibody design makes it the most compact, single-shot system for unconventional wells.

DS LoneStar is unmatched in explosive net energy delivered to the formation, length optimization, entry hole uniformity and overall downhole performance.

Case study

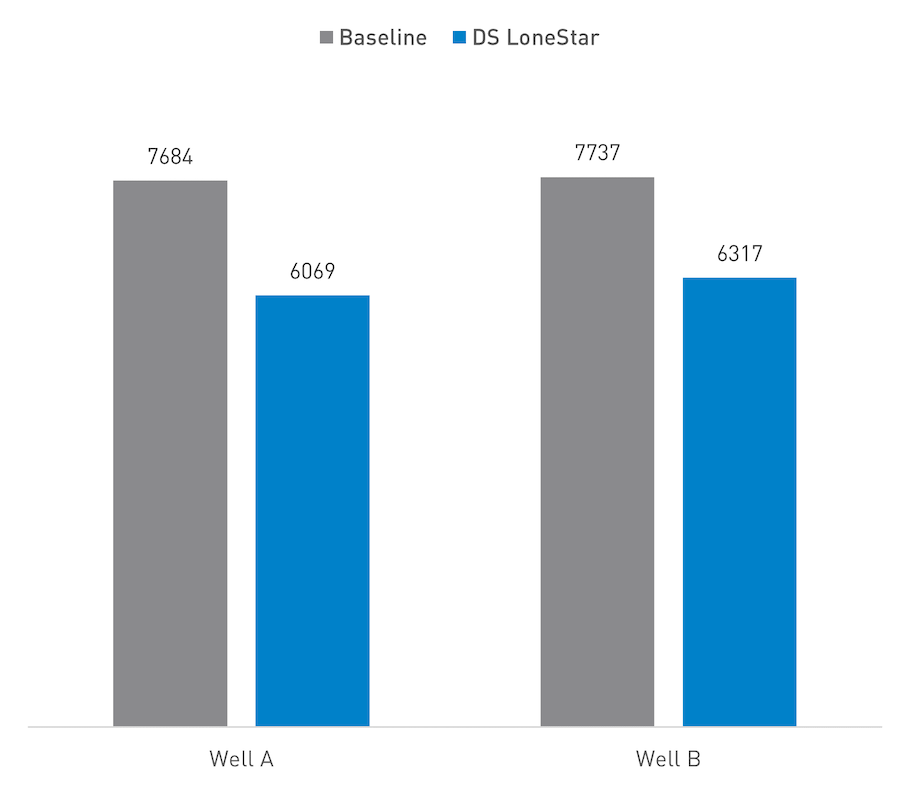

Two companies perforated multiple wells using different perforating technologies in multiple stages of each well. Conditions such as pump rate, proppant concentration and chemicals were all comparable.

The perforating design required an entry hole of 0.40-inch diameter, one shot per cluster oriented straight up at 0 degrees and 16 clusters per stage.

This article discusses results of two wells, but it should be noted that other wells showed comparable results.

- Well A: Lower Sprayberry Formation: test featuring five stages perforated with DS LoneStar and pumped with high-viscosity friction reducer fluids at 75 bbl/min, with no rate increase.

- Well B: Jo Mill Formation: test featuring seven stages perforated with DS LoneStar and pumped with slickwater fluid at 85 bbl/min.

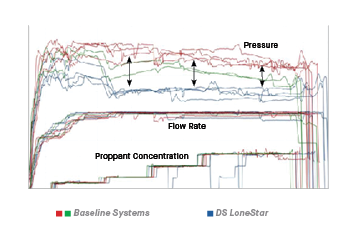

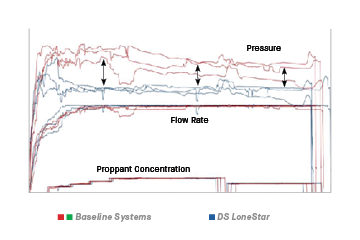

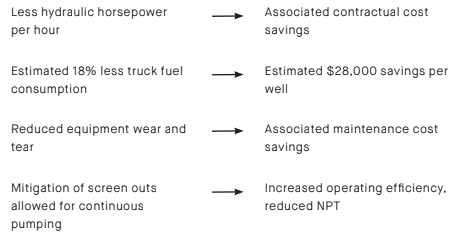

The pressure-rate-concentration curves overlayed for multiple stages show a significant reduction in treatment pressure for DS LoneStar (blue curves) compared to the other systems (red and green curves). DS LoneStar’s near-perfect perforation efficiency, with lower perforation friction, leads to uniform fluid distribution.

It is evident that average treating pressures are consistently lower for stages using the DS LoneStar system—in this application, 1,400 to 1,600 psi (18% to 21%) lower.

Average Treatment Pressure for Well A and Well B

Pressure Rate Concentration Curve: Well A

Pressure Rate Concentration Curve: Well B

Conclusions and observations

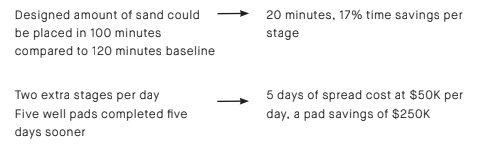

DS LoneStar delivered 100% perforation/cluster efficiency, more guns per stage or an “easier to pump” shorter gun string, significant reduction in treatment pressure of 1,400 to 1,600 psi (18% to 21%) and considerable increase in operational efficiency.

RELATED CONTENT:

Nov. 2, 2020 Boosting SWD Well and Producer Performance

Nov. 1, 2020 Recent Trends In Perforating For Limited-entry Stimulation

Feb. 18, 2020 Fine-tuning Perforations In Refractures

June 8, 2019 Perforating Systems Technology Showcase

Recommended Reading

NOG Closes Utica Shale, Delaware Basin Acquisitions

2024-02-05 - Northern Oil and Gas’ Utica deal marks the entry of the non-op E&P in the shale play while it’s Delaware Basin acquisition extends its footprint in the Permian.

Vital Energy Again Ups Interest in Acquired Permian Assets

2024-02-06 - Vital Energy added even more working interests in Permian Basin assets acquired from Henry Energy LP last year at a purchase price discounted versus recent deals, an analyst said.

California Resources Corp., Aera Energy to Combine in $2.1B Merger

2024-02-07 - The announced combination between California Resources and Aera Energy comes one year after Exxon and Shell closed the sale of Aera to a German asset manager for $4 billion.

DXP Enterprises Buys Water Service Company Kappe Associates

2024-02-06 - DXP Enterprise’s purchase of Kappe, a water and wastewater company, adds scale to DXP’s national water management profile.

Tellurian Exploring Sale of Upstream Haynesville Shale Assets

2024-02-06 - Tellurian, which in November raised doubts about its ability to continue as a going concern, said cash from a divestiture would be used to pay off debt and finance the company’s Driftwood LNG project.