Forum’s VMAX simulator was designed for training and engineering analysis. (Source: Forum Energy Technologies)

[Editor's note: A version of this story appears in the July 2020 edition of E&P. It was originally published July 1, 2020. Subscribe to the magazine here.]

In response to the demand for more efficiencies throughout the investment life cycle, new innovations and improved technologies continue to be adopted throughout the energy sector.

Seabed infrastructure is frequently designed, manufactured and deployed within a very challenging time frame and flaws in equipment or process design are often not identified prior to commencement of fabrication, particularly for large, complex structures.

During construction in subsea fields, equipment will be positioned, interconnected and activated using ROVs. Key to the success of such projects is the understanding of how ROVs will interact with the equipment and how effectively the equipment design and deployment procedures have anticipated this.

Design engineers, however, don’t always have a full understanding of ROV operations and can often overlook potential design flaws. This can result in elements of the design proving problematic for those piloting the vehicles remotely once in the field.

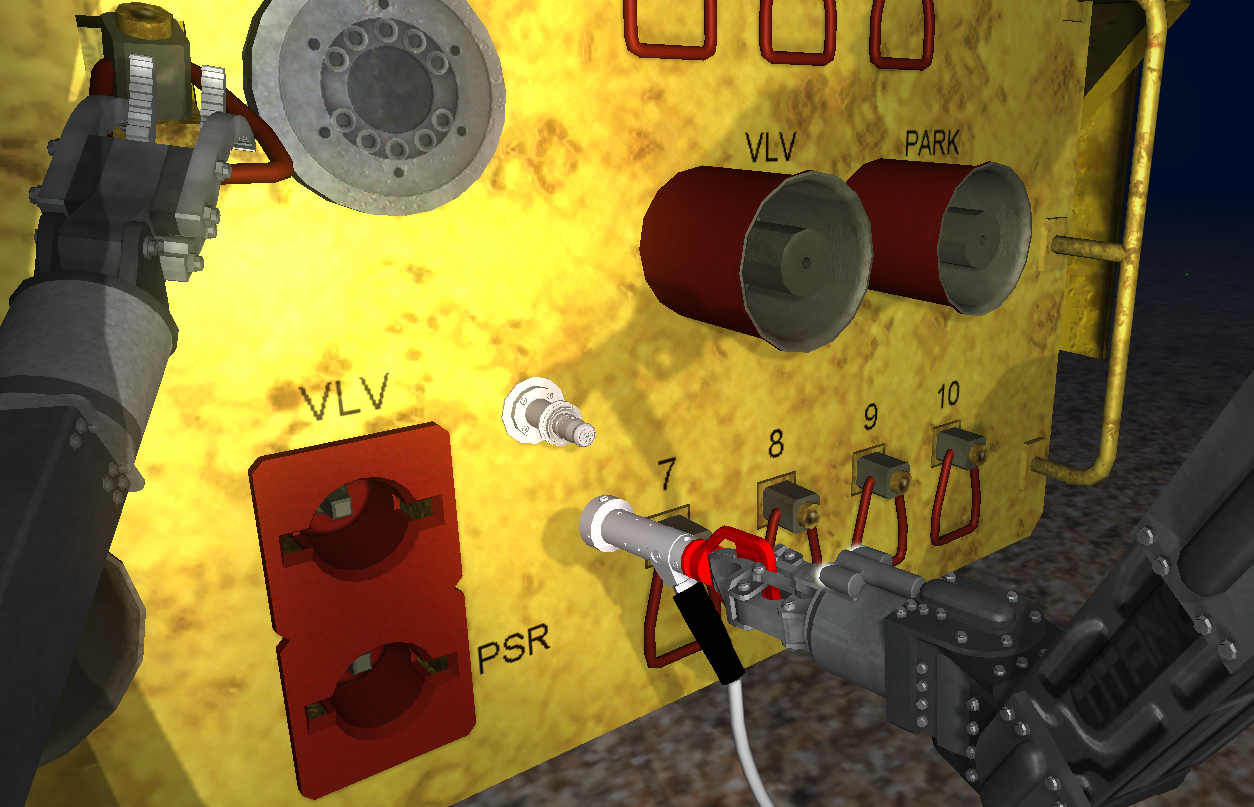

A simple example of this is the location of a grappling handle on a subsea tree. The grappling manipulator is usually mounted on the left side of the ROV. This manipulator, usually a rate-controlled robotic arm, is used to anchor the ROV to the equipment it will be working with. Often, engineers will design this manipulator’s handle on the right side of an access panel, either out of a desire for symmetry (matching a left-mounted handle) or the belief that this handle will facilitate access to interfaces on the right side of the panel. At best, this additional handle will be useless; at worst, it will inhibit useful actions on the panel.

There are countless other examples where knowledge may be lacking in a subsea engineering team, as many of the engineers will have no direct experience with operating in the subsea environment.

ROV simulation improves design

For years, organizations have been using simulated training to help ROV pilots learn how to operate the vehicles, and increasingly they are using the same software and learning experience to develop their engineers’ design skills.

Computer simulation can be used to greatly reduce engineering costs and risks to subsea projects and can significantly reduce project turnaround time. The definition of simulation, in this case, refers to rigid-body six-degree freedom simulations of subsea operations, complete with realistic 3D graphics, and some sort of hardware interface for controlling the simulation.

Forum Energy Technologies’ VMAX Simulation Software is similar to a flight simulator, except the pilot is flying an ROV rather than an airliner. VMAX comes complete with a variety of ROV scenarios designed to test pilot’s skills such as tether management, manipulator control and tooling operation within realistic operational conditions. These scenarios can be used as a training tool for ROV operators. It also can be used by subsea engineering teams looking to utilize the training and gain a deeper understanding of requirements needed to support modeling and verification of procedures involving ROV intervention tasks.

Simulation advances

Simulation opens up a new way to gain operational knowledge as it is relatively inexpensive to have an engineer use a desktop simulator to fly an ROV around.

Creating specific situations with models of the actual equipment being used for a subsea project allows engi neers to truly see how the ROV will interact with the equipment they have designed in the type of conditions that the equipment will be used in. The simulation will quickly show if another piece of equipment is in the way of operating a certain ROV panel on a manifold, which may not be obvious when designing the panel.

VMAX has supported this type of analysis for years. However, specialized personnel with extensive knowledge of 3D modeling and a background in coding were a prerequisite along with significant time to prepare the simulations, which all added to the costs.

This is no longer the case. Forum worked with its clients to develop new tools and processes to revolutionize the use of the simulator.

The traditional method of equipment verification involves taking hundreds of still shots of a modeled ROV performing subsea tasks to form the basis of an animated video. These images were created by puppeteering the ROV around a structure at the correct locations. This method is very time consuming, and the effects of the subsea environment cannot be modeled correctly, nor the resulting behavior of the ROV tether or constraints of ROV components such as manipulators and torque tools.

The VMAX system has proven to deliver a suite of tools that supports a smooth workflow from equipment model preparation to the construction of the scenario and, ultimately, to a successful simulation of the operation.

Importation tools for Solidworks and Inventor have been developed to simplify bringing equipment models into VMAX’s scenario development application, VMEditor. Engineering models may pose excessive complexity, which can add unnecessary processing overhead to the simulation. Instead, this editing function provides the opportunity to prepare each model for efficient use within the simulation.

The user-friendly VMEditor allows the engineer to create a workspace and position equipment models together as per the field design or in isolation. Collision geometries and physical properties are applied, and bespoke ROVs can be built if they are not found in the simulator library.

Most recently, VMAX has introduced several improvements including the ability to build simulation scenarios that allow equipment and ROV tooling to be selectable. So rather than building multiple scenarios or having to configure from the simulation load menu, tools and equipment can be simply switched on or off within the simulation.

Once complete, the scenario can then be used to simulate the project procedures. A variety of camera views allow a free-flying view so the operation can be viewed from any angle. The ROV flight can be recorded if required, but often screenshots of key events or problems identified are enough for analysis reports. And should the engineer wish to propose alternative designs or procedures, the process is sufficiently streamlined to deliver fast scenario revisions.

A key consideration in implementing simulation within an engineering department is the required outlay for equipment. Both VMEditor and VMAX ROV Simulator can be operated on a well-specified PC or laptop, which are typically used by design engineers. Control of the vehicle and tools can be adequately achieved using a good quality gaming joystick and keyboard buttons. Control of a seven-function manipulator also can be achieved this way; however, Forum’s recommended method is to use the Olis OS control software, which can be provided on either tablet or Master Controller format.

Road map to successful results

Forum’s approach to simulation as an engineering tool centers on its in-depth understanding of how engineering teams operate and what their skill sets are. This ensures a training road map is produced and any new tools required are already identified to ensure a smooth workflow. Ultimately, self- sufficiency is the goal, but support is always available when needed.

From an engineering perspective, VMAX is providing engineers with a realistic insight into what an ROV can and cannot do. A recent adopter of the technology reported a reduction in project validation costs of about 50% and an overall execution time reduction of about 60%, compared with their traditional workflow. This type of learning will go a long way to encouraging further innovations to support the ever-evolving sector’s needs.

Recommended Reading

US Drillers Cut Oil, Gas Rigs for Third Week in a Row, Baker Hughes Says

2024-08-30 - The rig count is 8% below this time last year, according to Baker Hughes.

Helix Awarded Vessel Service, Charter Contracts Off Brazil

2024-08-28 - Helix Energy Solutions Group was awarded new three-year charter and service contracts, valued at an estimated $786 million, from Petrobras for Siem Helix 1 and Siem Helix 2.

Shell, Akselos Enter Enterprise Deal for Structural Performance Management

2024-08-28 - Shell Information Technology International will leverage Akselos’ structural performance management software to monitor the health and lifecycle of Shell’s critical assets in Qatar, Canada, the Gulf of Mexico and elsewhere.

From Exxon to APA, E&Ps Feel Need to Scratch Exploration Itch

2024-08-27 - Exxon Mobil is looking for its “next Permian,” which an executive said could be in Algeria.

E&P Highlights: Aug. 26, 2024

2024-08-26 - Here’s a roundup of the latest E&P headlines, with Ovintiv considering selling its Uinta assets and drilling operations beginning at the Anchois project offshore Morocco.