First Solar plans to build its fifth photovoltaic solar module manufacturing facility in the U.S., investing up to $1.1 billion to add 3.5 gigawatts (GW) of nameplate capacity.

The Arizona-headquartered company said July 27 the new facility—the location for which has not been determined—will produce its Series 7 modules using U.S. materials. Production from the facility is expected to lift the company’s total manufacturing capacity to 25 GW globally and 14 GW in the U.S. by 2026.

“Driven by compelling market fundamentals, supportive trade and industrial policies and robust customer demand as reflected in our year-to-date bookings, total contracted in backlog and pipeline of mid- to late-stage opportunities, we are pleased to continue to expand and invest in domestic manufacturing in the United States,” First Solar CEO Mark Widmar said July 27 on the company’s second-quarter earnings call.

First Solar’s order backlog stands at about 78 GW through 2030.

If necessary permits and approvals are obtained, the facility should be complete in the first-half of 2026. Its Alabama facility is currently under construction.

First Solar’s decision to build another solar panel facility, backed by incentives in the Inflation Reduction Act (IRA) comes as demand for solar energy grows. Data from the U.S. National Renewable Energy Laboratory’s latest solar industry update show drivers of demand from late 2022 through early 2023 include large module inventories, declining module prices, supply chain normalization and incentives from the IRA and other policies.

“Since the announcement of the Inflation Reduction Act approximately one year ago, we have committed over $2.8 billion in capital investments into the United States across our existing Ohio manufacturing facilities, a new manufacturing plant in Alabama, a new research and development center in Ohio, and most recently, our fifth U.S. factory announced today,” Widmar said July 27. “We expect this will result in the creation of approximately 700 new direct jobs as well as multiples of this number in incremental indirect jobs, including across our supply chain.”

The company anticipates announcing the location of its newest facility “shortly.” Factors being considered, Widmar said, include suitable land availability and related infrastructure, proximity to existing supply chains, access to skilled labor and other factors such as state-level incentives.

In other news this week, First Solar said the company will provide 279 megawatts (MW) of advanced thin film solar panels for the Tennessee Valley Authority’s Lawrence County solar project in Alabama. The project is expected to start commercial operations in 2027.

Here is a look at other renewable energy news this week.

RELATED:

Venezuela Must Advance Renewable Developments, Official Says

TotalEnergies Acquires Total Eren, Grows Renewables Portfolio

Global Energy Watch: E-mobility, Alternative Transport and the Intersection of Change [WATCH]

Biofuels/RNG

SunGas Renewables Forms Beaver Lake to Build $2B Green Methanol Facility

Houston-based GTI Energy spinout SunGas Renewables Inc. has formed a subsidiary that will build a $2 billion green methanol facility in Louisiana, transforming a former International Paper Co. facility in Rapides Parish.

Wood fiber will be used to make the green methanol, the company said.

The investment was announced on July 26 as demand for green fuels rises. The subsidiary, called Beaver Lake Renewable Energy LLC, plans to produce nearly 400,000 metric tons (mt) of green methanol per year for marine fuel, SunGas said in a news release. It will be used to power A.P. Moller-Maersk’s fleet of vessels.

“Using biomass from sustainably managed forestry along with carbon capture allows our project to generate green marine shipping fuel while simultaneously removing carbon from the atmosphere,” SunGas Renewables CEO Robert Rigdon said in the release.

The project will have a negative carbon intensity as Denbury Carbon Solutions has been tapped to sequester nearly a million tons per year of CO2 produced by the project.

Construction of the facility is set to begin in late 2024 with operations starting in 2027.

RELATED

Synthica Energy Begins Construction of Ohio RNG Plant

Repsol to Invest More Than $130MM to Retrofit Plant to Produce Biofuels

Energy Storage

RWE Brings Texas Battery Storage Online Amid Heat Wave

RWE has brought its 30-MW Texas Waves II co-located battery storage facility online in Texas, the company said July 24.

Located at the Pyron Wind Farm in Scurry, Texas, southeast of Lubbock, the facility features a 1-hour lithium-ion battery and provides ancillary services to the energy market and grid operator Electric Reliability Council of Texas (ERCOT).

The project follows Texas Waves I, two 9.9-MW short duration energy storage projects that went online in 2017 at the RWE Pyron and Inadale wind farms in West Texas.

“This new battery storage system helps us make progress against our Growing Green Strategy to achieve net-zero by 2040 goal, while providing a rapid and flexible response asset to the Texas power grid,” RWE Clean Energy CEO Mark Noyes said in a news release. “As this summer’s heat drives all-time energy demand records in Texas, renewable energy, including battery energy storage, is contributing to relieving stress on the grid.”

Battery energy storage systems store energy from various sources and discharge it when needed such as when demand exceeds supply. Though Texas has issued weather watches this summer after seeing electricity demand hit record highs, supplies have kept up pace. ERCOT said it set an all-time maximum peak demand record of 80,787 MW on June 27, surpassing its previous all-time record of 80,148 MW set on June 20, 2022.

Texas has recorded numerous days of triple-digit temperatures at or above 100.

RWE said it currently has about 2.5 gigawatt-hours (GWh) of battery storage projects underway in the U.S.

Enevate, JR Energy Solutions Partner to Build Battery Electrode Facility

California-based Enevate Corp. and Korea’s JR Energy Solution (JR ES) will jointly build a 6-GWh battery cell electrode manufacturing facility in the U.S.

The facility will produce lithium-ion battery cell electrodes, including anodes and cathodes, and provide various electrode solutions, Enevate said in a July 24 news release.

The manufacturing facility is part of a collaboration in which Enevate will license its XFC-Energy battery technology to JR ES, which is also building its first production facility in South Korea. JR ES manufactures lithium-ion battery electrodes.

“This collaboration with JR Energy Solution is great news for the whole battery industry in the U.S.,” said Enevate CEO Bob Kruse. “It will allow customers to get access to Enevate’s industry-leading silicon-dominant battery technology and to tap into JR ES’ knowledge and expertise in electrode and battery cell manufacturing.”

The companies are identifying potential locations, Enevate said.

Arizona Lithium Raises $10M to Advance Prairie Lithium Project

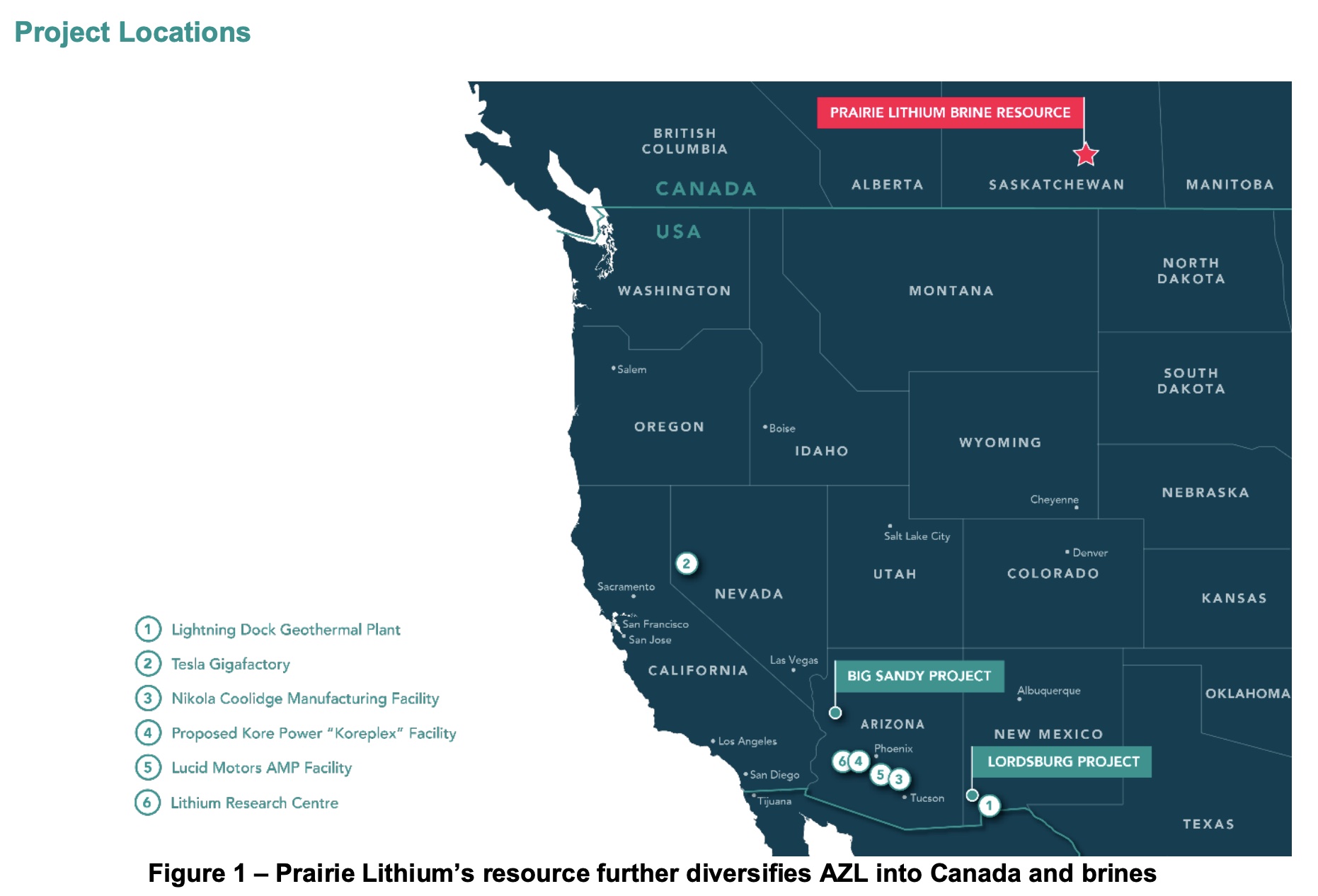

Arizona Lithium said July 28 it has received firm commitments of $10 million to move its Prairie lithium project forward in the Williston Basin of Saskatchewan, Canada.

The commitments were made through share placement to institutional and professional investors at $0.025 per share with one free attaching option per one new share, the company said in a news release.

Funds will also be used to complete construction of a lithium research center, which Arizona Lithium said will enable treatment of bulk samples from the Big Sandy Lithium project in Arizona. The center, located in Tempe, Arizona, will serve as a technology incubator.

Considered a critical mineral in short supply, the U.S. has been working to increase domestic production and processing of lithium, which is used to make batteries for electric vehicles (EV). Lithium demand is expected to grow by 43 times by 2040 amid rising demand for EVs, according to the International Energy Agency.

Described as “very shallow, flat lying mineralized sedimentary lithium resource,” Big Sandy has a mineral resource potential of about 271 million tonnes (MMtonne) to 483 MMtonne, the company said.

Arizona Lithium’s exploration permit seeks a proposed 145 exploration holes and a bulk sample at the Big Sandy Lithium. The permit application is under review by the Bureau of Land Management.

The company’s Prairie lithium project, which involves extracting lithium from brine, “holds the highest quality inferred lithium brine resource in Canada, with 4.1 [MMtonne]” plus expansion potential.

RELATED: As China Dominates, Private Capital Vital for US Critical Minerals

Hydrogen

Germany’s Updated Hydrogen Strategy Sees Heavy Reliance on Imported Fuel in Future

Germany will have to import up to 70% of its hydrogen demand in the future as Europe’s largest economy aims to become climate-neutral by 2045, an updated government strategy published on July 26 showed.

The German cabinet approved a new hydrogen strategy, setting guidelines for hydrogen production, transport infrastructure and market plans.

Germany is seeking to expand reliance on hydrogen as a future energy source to cut greenhouse-gas emissions for highly polluting industrial sectors that cannot be electrified such as steel and chemicals, and cut dependency on imported fossil fuel. Produced using solar and wind power, green hydrogen is a pillar of Berlin's plan to transition away from fossil fuels.

But even with doubling the country’s domestic electrolysis capacity target for 2030 to at least 10 GW, Germany will need to import around 50% to 70% of its hydrogen demand, forecast at 95 terawatt-hours to 130 terawatt-hours in 2030, the strategy showed.

“A domestic supply that fully covers demand does not make economic sense or serve the transformation processes resulting from the energy transition as a whole,” the document said.

The strategy underscores the importance of diversifying future hydrogen sources but the government is working on a separate strategy for hydrogen imports whose exact date is not clear, a spokesperson for the economy ministry said.

Under the strategy, state aid is expected to be approved for around 2.5 GW of electrolysis projects in Germany this year, and the government will earmark 700 million euros (US$775 million) for hydrogen research to optimize production methods, research minister Bettina Stark-Watzinger said.

But Germany’s limited renewable energy space will make it heavily dependent on imported hydrogen, experts say.

RELATED: Bloom Energy Launches New Fuel Cell Offering

Solar

US: Largest Solar Project Could Be Built on Energy Department Land

The largest solar U.S. project and other clean energy infrastructure could be built on re-purposed land owned by the Department of Energy (DOE), including part of a site contaminated during the production of Cold War-era atomic bombs, the agency said July 28.

The DOE said it has identified about 70,000 acres it owns that could eventually be home to clean energy projects including solar, wind and nuclear power.

Sites identified for potential development include: Hanford Site, Richland, Washington; Idaho National Laboratory, Idaho Falls, Idaho; Nevada Nuclear Security Site, Nye County, Nevada; Savannah River Site, Aiken, South Carolina and Waste Isolation Pilot Plant, Carlsbad, New Mexico.

The U.S. government built the Hanford and other complexes in the 1940s to produce plutonium and uranium for atomic bombs under the Manhattan Project. Hanford is now decommissioned and too contaminated for public use.

RELATED:

Hexa Renewables to Develop 1 GW of Hybrid Solar Projects

Altus Power Adds Massachusetts Solar System, Battery Storage

Canada's Heliene Plans New US Solar Panel and Cell Factory

Wind

Construction Underway for Acciona Energía’s Wind Farm in Alberta

Spain-headquartered Acciona Energía said July 26 construction has begun on its largest wind farm project in North America, the 280-MW Forty Mile wind project in Alberta, Canada.

Developed by Renewable Energy Systems Canada, the wind farm features 49 Nordex turbines with the potential to grow to 400 MW with a second phase. Construction is expected to be complete in first-quarter 2025, Acciona said in a news release.

The company currently operates and owns four wind farms in Canada with a combined wind capacity of more than 180 MW.

Ørsted Sells Remaining Stake in London Array Wind Farm

Asset manager Schroders Greencoat is buying a 25% stake in the 630 MW London Array wind farm offshore the U.K. from Denmark’s Ørsted.

The deal, expected to close at the end of July, is valued at about US$920 million (GBP 717 million), Ørsted said on July 24.

The company said it considers the asset, where it has no operations and maintenance responsibility, as non-strategic, though it remains committed to the U.K.’s offshore wind sector.

“We continue to see significant appetite for offshore wind as an asset class, and with this divestment, we continue our unrivalled track record of efficiently recycling capital to help fund our DKK 475 billion investment program towards 2030,” Ørsted CFO Daniel Lerup said in a news release.

Other shareholders in the wind farm, which began operating from the Port of Ramsgate in 2012 and now features 175 wind turbines with two offshore substations, include RWE, Caisse de dépôt et placement du Québec and Masdar is Abu Dhabi’.

Hart Energy Staff and Reuters contributed to this report.

Recommended Reading

ProPetro to Provide eFrac Services to Exxon’s Permian Operations

2024-04-29 - ProPetro has entered a three-year agreement to provide electric hydraulic fracturing services for Exxon Mobil’s operations in the Permian Basin.

Keeping it Simple: Antero Stays on Profitable Course in 1Q

2024-04-28 - Bucking trend, Antero Resources posted a slight increase in natural gas production as other companies curtailed production.

Oil and Gas Chain Reaction: E&P M&A Begets OFS Consolidation

2024-04-26 - Record-breaking E&P consolidation is rippling into oilfield services, with much more M&A on the way.

Exxon Mobil, Chevron See Profits Fall in 1Q Earnings

2024-04-26 - Chevron and Exxon Mobil are feeling the pinch of weak energy prices, particularly natural gas, and fuels margins that have cooled in the last year.

Marathon Oil Declares 1Q Dividend

2024-04-26 - Marathon Oil’s first quarter 2024 dividend is payable on June 10.