(Source: Josie Elias/Shutterstock.com)

Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

CCUS and net zero

Carbon capture, storage and utilization (CCUS) technologies will play a key role in transitioning the energy sector toward a net-zero future. Carbon storage is the process whereby CO2 captured from emission sources, such as industrial sites, is separated, transported and injected into suitable deep geological formations for permanent storage. The CO2 can be stored for decades with a low risk of leakage to the atmosphere and environment. Where CO2 cannot be utilized for building materials, chemicals and other products, then permanent storage in suitable formations provides a net-zero solution.

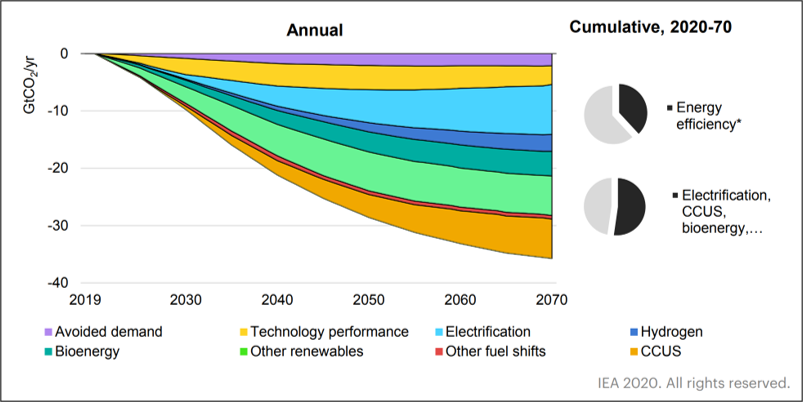

According to the IEA Sustainable Development Scenario (see reference 1), CCUS is expected to contribute to nearly 15% of the expected cumulative reduction in CO2, growing over time. This will account for nearly one-sixth of cumulative emission reductions by 2070 (Figure 1). To achieve these targets, CCUS storage capacity will need to be scaled up by a factor of 20 by 2030 to store and utilize 840 Mt of CO2, which is well beyond current estimates of 40 Mt (IEA, 2020).

Barriers to CCUS deployment and risks

Large-scale project deployment has been relatively slow in the last two decades due to a whole range of factors. Some areas that have acted as barriers to attainment of the required CCUS target CO2 emission reductions under the IEA 2020 Sustainable Development Scenario are summarized in the table below (see reference 2).

Barriers to Large-scale CCUS Implementation |

|||

Technical |

Economic |

Market |

Political/Legal |

| Subsurface risks (e.g., leakage) | Capex/Opex variability | Market for CO2 products (utilization) | Lack of regulation |

| Project integration risks | Lack of a revenue model/business case | Industrial sector growth | Policy uncertainty (e.g., emerging countries) |

| Project performance | Limited access to finance | Transport business | Long-term liabilities/insurance |

| Utilization technologies | Transport and storage costs | Electricity growth (CCS and other clean energy industries) | Lack of legal framework |

(Source: Coll, SPE workshop 2020)

The main risks range from technical aspects, such as subsurface understanding, through project performance and technology to economics (e.g., project costs and revenue models) and access to financing. Market, political and legal aspects are other risk areas that will impact the delivery of CCUS projects at the scale required to meet net-zero targets.

Role of geoscience in CCUS

While significant progress has been made in CCUS over the last five years, the industrial and financial sectors need to see how projects are being effectively de-risked. By capitalizing on the latest technology advances and the integration of multidisciplinary skills and data, geoscience has a critical role to play in de-risking for CCUS developments.

The technical aspects are some of the most important risks that need addressing and are precisely where geoscience has a pivotal role to play. This is true throughout the life cycle of CCUS projects and also hydrogen storage. Given their complexity, they require expertise from several areas of geoscience and engineering that has, historically, already been successfully applied to many large and complex projects in the oil and gas industry.

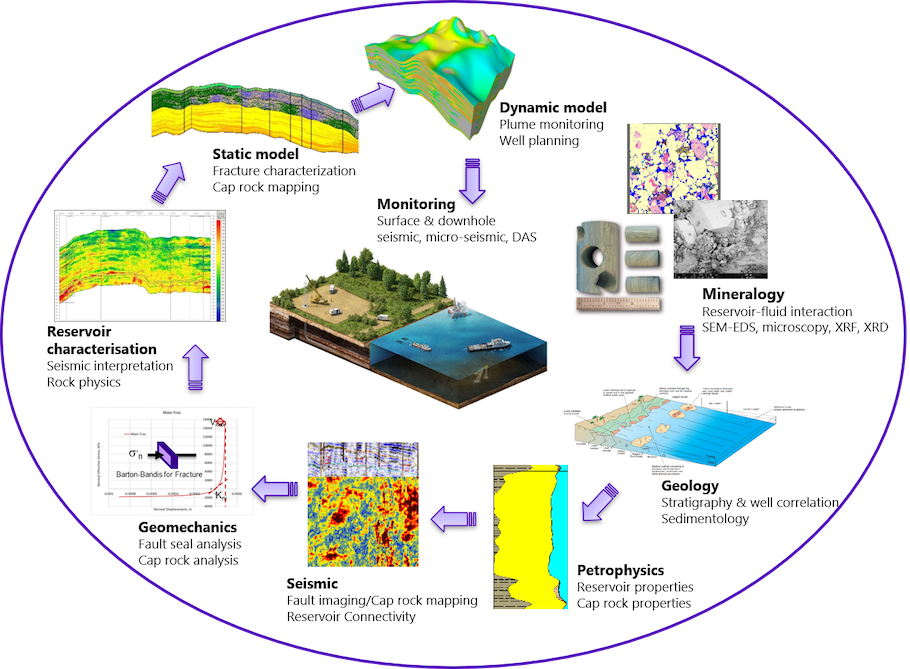

Assessing subsurface risk requires integration of key geoscience disciplines, ranging from geophysics, geology and petrophysics to reservoir and completion engineering. CCUS projects require storage screening to identify potential sites, detailed storage evaluation to determine capacity, containment and injectivity estimations to optimize operations during injection, and long-term monitoring to ensure safety and to satisfy regulatory requirements.

CGG can support clients and partners to evaluate subsurface risk based on its unique capabilities to image the subsurface, integrate subsurface data and perform reservoir modeling. The company's teams are involved in new initiatives to repurpose its extensive geoscience databases and workflows to help clients reduce the time cycle during storage evaluation, speeding up the identification of new potential CCUS projects, and better assess uncertainty and risk.

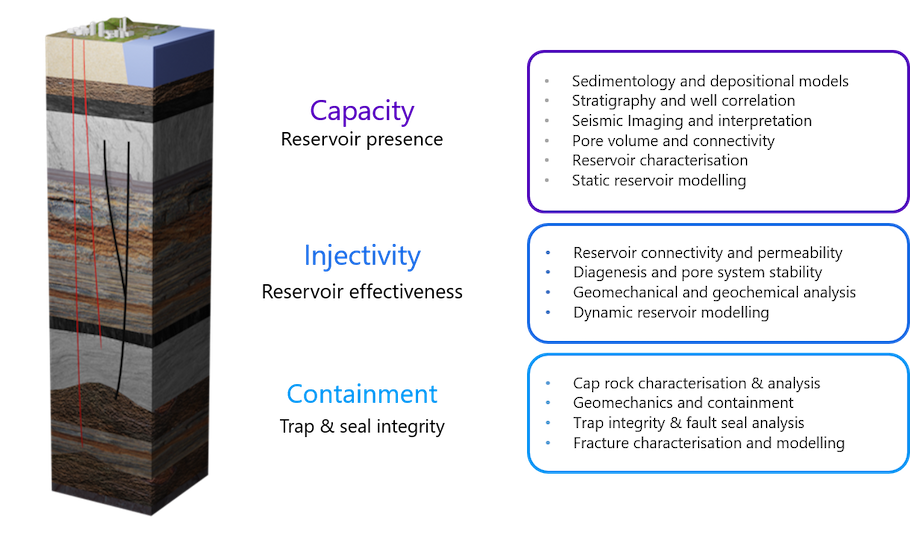

For storage screening, for example, CGG's multiclient data and GeoVerse carbon storage screening products (see reference 3) can help CCUS operators quickly identify suitable storage sites in depleted oil and gas reservoirs and aquifers. For storage evaluation, the three key areas that require investigation are containment, capacity and injectivity (Figure 2).

Assessing containment risk requires evaluation of the caprock and trap integrity using sophisticated geomechanical models as well as imaging techniques for fault seal analysis and fracture characterization. Integrated reservoir characterization (Figure 3) is also essential to understand reservoir capacity by analyzing well data and seismic information for reservoir characterization and connectivity to build realistic reservoir models. The amount of information available will depend on the type of permanent CO2 storage. In the case of depleted oil and gas reservoirs, the reservoirs have proven seals and traps, although the reservoir behavior under re-pressurization is often unknown.

Understanding injectivity is another key factor to determine the number of injector wells required and injection rates. This is an important parameter for an economic assessment. Reservoir connectivity and permeability, diagenesis and pore system stability as well as geomechanical effects will determine the operational limits of injection, and this can be evaluated using dynamic reservoir modeling. With CGG’s seismic imaging methods and integrated workflows, the company can estimate the displacement of a CO2 plume in the reservoir; the potential reactivation of faults due to CO2 pressurization and injection; undesired migration of the injected CO2 plume (leading to leakage to the surface); and reservoir uncertainty.

CO2 is usually injected as a supercritical fluid, meaning that the pressure of CO2 storage reservoirs is high. CGG can apply its geomechanics expertise using proprietary tools, such as its GEOSIM coupled geomechanical reservoir simulator to model fracture initiation/propagation and caprock breach due to CO2 injection, to help define injectivity, to determine safe operating envelopes during injection and design evaluation wells to reduce project- and economics-related risks.

Detailed engineering studies are also critical to ensure wells are handled safely to avoid any leakage to nearby reservoirs, aquifers or the surface.

Analysis of all these aspects is required to determine whether geological formations are suitable for CO2 containment or not. In many cases, depleted oil and gas wells are good candidates for storage as they are already proven containers of fluids, which means that the CO2 containment risk is better understood.

On the monitoring side, CGG is developing new technologies and workflows toward the objective of achieving what it has branded as “Fit-for-Purpose Monitoring” for CCUS (see reference 2). For this, the company can leverage its outstanding capacity to process and integrate many different types of data and information, ranging from satellite InSAR, gravity and electromagnetic measurements, 3D/4D seismic imaging, reservoir models and well data, that will help operators meet CCUS regulatory requirements. This also includes new options for permanent monitoring services with the development of new sensors, acquisition and monitoring solutions developed by CGG’s equipment division, Sercel.

Collaboration opportunities

With a close eye on emerging technologies, CGG is keen to collaborate and share expertise with other CCUS specialists and consortia and has already recently partnered with Geoptic to apply its Muon imaging technology to CCS and hydrogen storage (see reference 4).

CCUS has seen a rapid growth in the last five years with the announcement of more than 30 new commercial facilities. Projects have diversified to other areas beyond the energy sector into industrial hubs, including industries like cement, steel and hydrogen facilities. Investment has grown from 2017, doubling to potentially US$27 billion in projects approaching a final investment decision. This portfolio of projects requires huge support from across the geoscience disciplines to minimize risk and ensure successful deployment. CGG believes that, with its proven geoscience capabilities and participation in such initiatives, the company is well placed to shape the future of CCS and hydrogen projects supporting the growth required to meet net-zero targets.

References:

- Special Report on Carbon Capture Utilisation and Storage CCUS in clean energy transitions (IEA, 2020)

- C. Coll, “The future of Monitoring for CCUS”. Geosciences Technology AAPG Workshop. High CO₂, High Contaminant Challenging Fields and Alternative Energy - Impact and Monetization (A Joint Workshop with EAGE). 23-25 November 2021 (Virtual)

- CGG Delivers New Multi-Client Screening Study for CO2 Storage Sites in UK and Norway Northern North Sea. Nov 25, 2021. www.cgg.com

- CGG and Geoptic Sign R&D Collaboration Agreement for Carbon Capture & Storage Monitoring. 27 May, 2021. www.cgg.com

Recommended Reading

WTI Delivered to East Houston Hits Highest Premium in Nearly Three Years

2024-05-01 - Oil takeaway capacity from the Permian Basin will tighten next month due to scheduled pipeline maintenance.

CPS Closes $785MM Deal for Talen Energy’s Texas NatGas Plants

2024-05-01 - CPS Energy has acquired all assets associated with the 897-MW Barney Davis and 635-MW Nueces Bay natural gas plants in Corpus Christi, Texas, and the 178-MW natural gas plant in Laredo, Texas.

Repsol Plans to Double Oil Production in Venezuela

2024-05-01 - Spain’s Repsol plans to double its oil production in Venezuela and continue with its diluent swap agreements with the OPEC country as approved by the U.S. government.

Permian Gas Finds Another Way to Asia

2024-04-30 - A crop of Mexican LNG facilities in development will connect U.S. producers to high-demand markets while avoiding the Panama Canal.

ARC Resources Adds Ex-Chevron Gas Chief to Board, Tallies Divestments

2024-02-11 - Montney Shale producer ARC Resources aims to sign up to 25% of its 1.38 Bcf/d of gas output to long-term LNG contracts for higher-priced sales overseas.