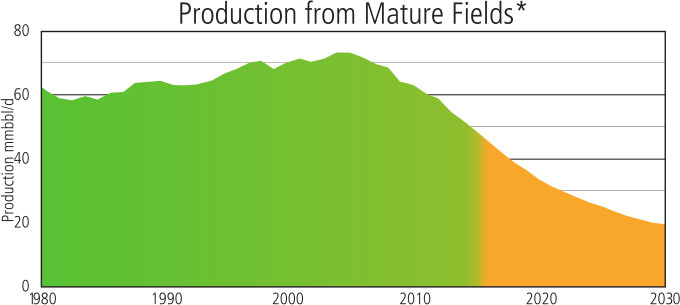

The old adage, “the best place to find oil is where it has been found already,” helps explain why more than 70% of global oil and gas production comes from fields that are more than 30 years old. Mature fields, commonly described as developments that have produced more than 50% of their reserves, are predictable in terms of both production and revenue. Infrastructure is in place. However, as production curves decline and the production infrastructure ages, these fields become technically, operationally and economically challenging.

The challenge is magnified in today’s low-price oil environment. Contrary to the notion that the life of a producing asset ends when production runs out, the reality is that the life of the asset ends when profit runs out. This situation presents a conundrum for many operators. For example, an E&P company executive said in an EPmag.com article, “Work on mature fields is absolutely essential for us if we want to meet our objectives.”

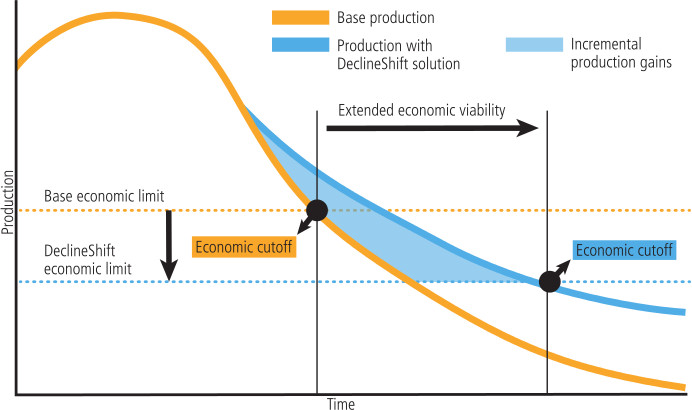

The decline of an asset’s production curve is inevitable, but a more strategic approach to life-cycle management can slow the process and shift the profitability decline. Historically, the most common approach to extending field life has involved measures to tighten opex and/or boost production. However, these measures offer only temporary relief. Extending the profitable life of a mature asset in the current price environment requires an aggressive strategy that focuses on maximizing capital efficiency and returns by spending intelligently on both opex and capex.

Shifting the decline

Baker Hughes has formalized an approach to prolonging the profitability of mature assets in a solution called DeclineShift. The objective is to shift the production and profitability decline of a mature asset based on understanding the individual asset—including the operating environment and what has been done to the field—and the operator’s drivers, and leveraging advanced technologies and services to design and implement a fit-for-purpose solution aligned with those drivers.

The solution follows a phased approach that begins with a close examination of the areas that—individually and collectively—have the greatest impact on the operator’s objectives and drivers for the asset. The examination can range from individual well diagnostics to full-field analysis and typically focuses on three primary challenges:

1. Optimizing production from existing wells by rejuvenating producing wells or reactivating shut-in wells;

2. Maximizing production revenue by optimizing flow (e.g., using advanced chemical services and artificial lift technologies to improve hydrocarbon quality and lift efficiency or minimizing downtime by mitigating undesirable production of byproducts and avoiding deferred production); and

3. Increasing economically recoverable reserves by identifying, quantifying and accessing bypassed hydrocarbons or extending field life using sound reservoir management practices such as optimizing displacement efficiency and controlling reservoir pressures.

Optimizing production by reactivating wells

Surface-controlled subsurface safety valves (SCSSVs) are a vital part of the overall safety system in a producing well. The valves protect the environment, protect assets and, ultimately, protect lives. Government and regulatory bodies around the world have made them mandatory during the completion or workover phase of a well. Specifically, a national oil company (NOC) in the United Arab Emirates has a policy that requires naturally flowing oil and gas wells to have SCSSVs in place.

Over time, numerous SCSSVs in mature fields have become inoperable because of hydraulic control line leaks or blockages. When this situation occurs, wells often are shut in for long periods awaiting availability in lengthy workover rig schedules.

When two wells in a mature field in Abu Dhabi that had previously produced an average of 2,500 bbl/d were shut in because of plugged SCSSVs, the NOC opted for a mature asset well reactivation solution that would enable rigless operations to quickly restore well integrity while minimizing the wellsite footprint and disruption.

The solution included deploying a safety valve system that does not require a workover rig and uses reliable, field-proven capillary and safety valve technology to rapidly restore the safety barrier with the same surface control as originally designed for the well. A new hydraulic conduit controlled the safety valve, and an existing port in the christmas tree was used for tie-in to the emergency shutdown system.

The entire installation was completed in three days, vs. two to three weeks for a workover, and the integrity of all existing surface equipment remained completely uncompromised. Reactivating the two idle wells returned their production to 2,500 bbl/d per well and immediately increased revenue by $500,000 per day. Payback was accelerated by avoiding the long workover queue, and intervention costs were reduced by 66%.

Maximizing production revenue by optimizing flow

The economic viability of a 30-year-old field in Asia was challenged by high-profile pipeline failures, rapidly increasing secondary treatment costs, souring conditions and off-spec crude cargoes. The aging field contained several hundred onshore and offshore wells, more than 100 platforms and more than 2,000 pipelines. Production was about 200,000 bbl/d and 198,000 boe/d. The operator’s objectives were to address production chemical management and lower total cost of operation in a safe, environmentally sensitive manner using local content.

Baker Hughes was selected as the service partner. The flow optimization solution was implemented through a comprehensive production chemical management contract. The solution was efficiently and effectively executed through close operator/service-partner collaboration that included integrating the service company team into the operator’s production chemistry department, enabling the teams to meet a series of mutually developed key performance indicators.

Thirty-six of the 40 chemical-applications engineers and technicians who comprised the service company team were in-country residents, which helped improve communications and service delivery. The close relationships between the two teams also helped facilitate a shared, proactive approach, resulting in less downtime from unanticipated issues.

The solution resolved pipeline integrity issues safely with a combination biocide and pipeline inspection program. Pipeline integrity management reduced maintenance and inspection spend by $56 million/year and deferred capex for the operator. Drag-reducing agents helped improve production volumes through existing pipelines, accelerating production and increasing throughput by 5,000 bbl/d. Demulsifier programs confirmed that crude specifications were met and helped eliminate deferred production and tanker demurrage. The operator’s realized 700% return on investment from the total production chemical management contract reduced emulsion treatment cost by more than 50% and eliminated major pipeline failures to help extend field life.

Holistic field life extension increases recovery

Production from an 80-year-old field in Latin America that is recognized as one of the most complex in the world was declining by 6% monthly. New development wells were believed to be too costly. Previous revitalization attempts had been ineffective, so the operator requested a customized mature field solution in which the service partner assumed management of the field, including all technical and operational aspects, and developed and prioritized a portfolio of production enhancement opportunities.

Working in close collaboration, a holistic mature asset solution over a three-year period was designed and executed. The solution leveraged precise target characterization technologies, created more streamlined well designs and incorporated self-powered production pads using the wells’ gas supply to improve capital efficiency. A broad mix of fit-for-purpose technologies and services, including remote-operations services, were deployed. Thirty wells were drilled and completed, 36 recompletions and 86 workovers were performed, and 77 wells were fractured.

Following implementation of the solution, production increased by 300%, from 2,600 bbl/d to 10,500 bbl/d in the first 12 months. Operation costs dropped 57%, from $4.38/boe to $1.86/boe during the first 18 months. An additional 20,000 bbl of incremental production was realized through strategic well completions and interventions, and the monthly field production decline was cut almost in half to 3.4%. The consistent focus on capital efficiency yielded precise technical solutions to lower cost per barrel and reduced overall field decline, successfully extending the economic life of the asset.

Recommended Reading

Global Oil Demand to Grow by 1.9 MMbbl/d in 2024, Says Wood Mac

2024-02-29 - Oil prices have found support this year from rising geopolitical tensions including attacks by the Iran-aligned Houthi group on Red Sea shipping.

Oil Dips as Demand Outlook Remains Uncertain

2024-02-20 - Oil prices fell on Feb. 20 with an uncertain outlook for global demand knocking value off crude futures contracts.

What's Affecting Oil Prices This Week? (March 18, 2024)

2024-03-18 - On average, Stratas Advisors predicts that supply will be at a deficit of 840,000 bbl/d during 2024.

Oil Broadly Steady After Surprise US Crude Stock Drop

2024-03-21 - Stockpiles unexpectedly declined by 2 MMbbl to 445 MMbbl in the week ended March 15, as exports rose and refiners continued to increase activity.

Russia Orders Companies to Cut Oil Output to Meet OPEC+ Target

2024-03-25 - Russia plans to gradually ease the export cuts and focus on only reducing output.