BP’s Argos semisubmersible production platform, moored in 4,500 ft of water, has gone onstream 6 miles away from the Mad Dog spar. (Source: BP)

Editor's note: This article had been updated to include interviews with Argos' general manager and BP’s senior vice president for GoM and Canada.

First oil has begun at BP’s Argos production semisubmersible in the deepwater Gulf of Mexico (GoM) just six miles away from the Mad Dog truss spar, the operator announced on April 13.

Named Argos as a nod to Odysseus’ loyal dog from Homer’s "The Odyssey," getting the Mad Dog Phase 2 project over the finish line has been something of a journey for BP.

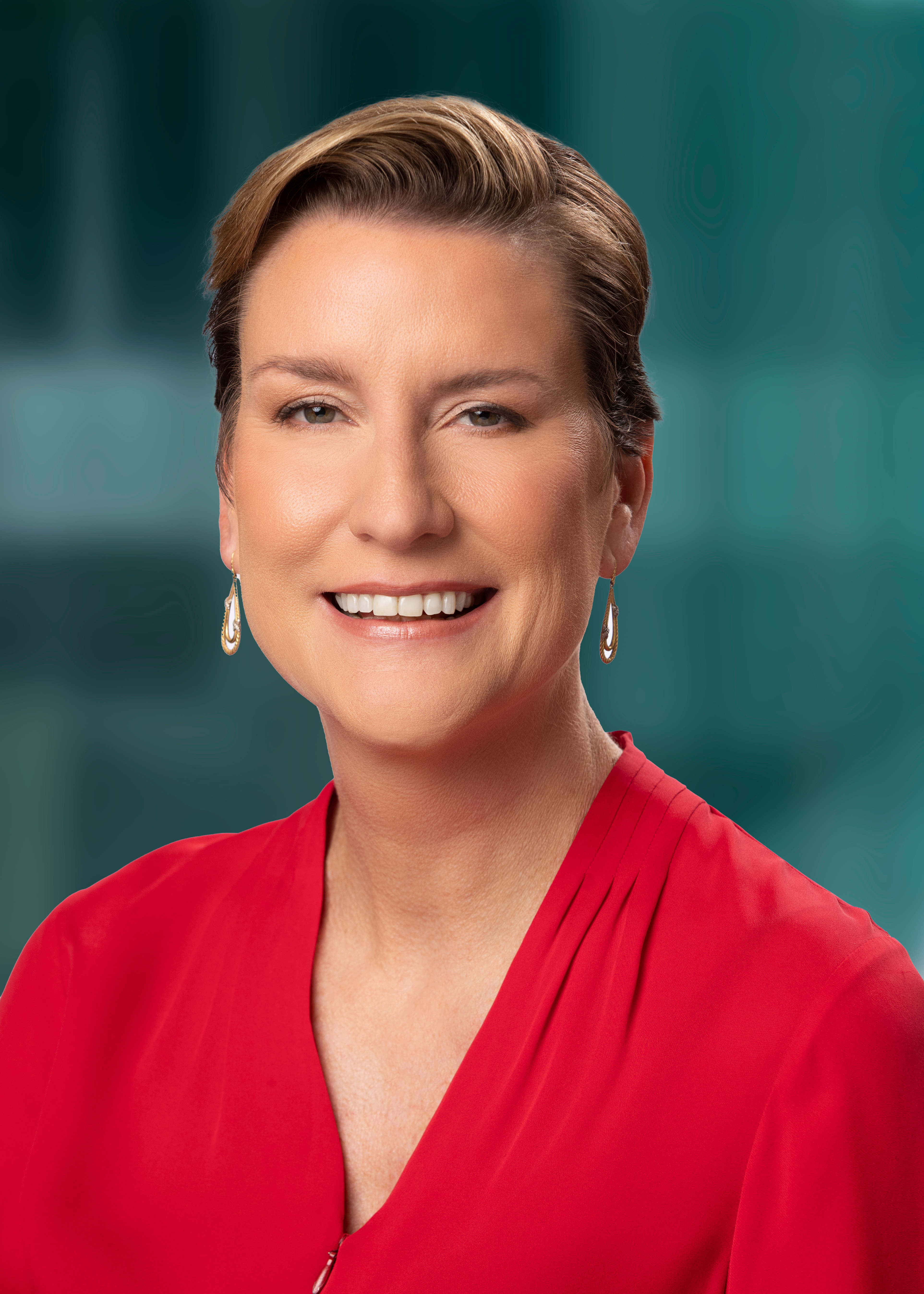

Starlee Sykes, BP’s senior vice president for GoM and Canada, told Hart Energy there was a lot of excitement as the first well producing to the Argos semi started ramping up this week. She said the $9 billion project came in safely and on budget, although it was delayed by the COVID-19 pandemic.

A long journey

The Mad Dog Field, discovered in 1998, began producing to a spar in 2005. Appraisal drilling in 2009 and 2011 at Mad Dog doubled the field’s resource estimate to more than 5 Bboe in place, and BP decided to use a second platform to produce the additional reserves.

In 2013, BP and its partners scrapped initial spar-based development plans for the Phase 2 project as too complex and costly with many execution risks, Chris Ruthven, Argos project general manager, told Hart Energy.

In late 2016, BP sanctioned a simplified and standardized platform design that reduced project costs by about 60%, from over $20 billion down to $9 billion, that was expected to begin production in 2021.

“I've been involved in projects for most of my career and anything at this scale is going to have some challenges,” Sykes said. “We weren't anticipating the pandemic, as you can imagine.”

The pandemic caused some delays with construction on the semi, while a few technical challenges caused some delays after the semi was on site in the Gulf of Mexico.

“As we got closer to first oil, we did have some technical challenges around some of the components of the project,” she said. “Nothing extraordinary, based on the kind of projects I've been involved with that have had much larger issues.”

Construction of the Argos offshore platform began in 2018 by Samsung Heavy Industries in South Korea. In 2021, Argos arrived at Kiewit Offshore Services fabrication yard in Ingleside, Texas, after a two-month, 16,000-mile journey onboard the Boskalis BOKA Vanguard heavy transport vessel.

Other major contracts went to Worly for contracting support, Subsea7 for engineering and installation, OneSubsea for the major subsea equipment and Honeywell for the automation.

Following final preparations and regulatory inspections, the semi was towed 380 miles offshore to the Green Canyon area of the Gulf of Mexico for final hook up and commissioning work.

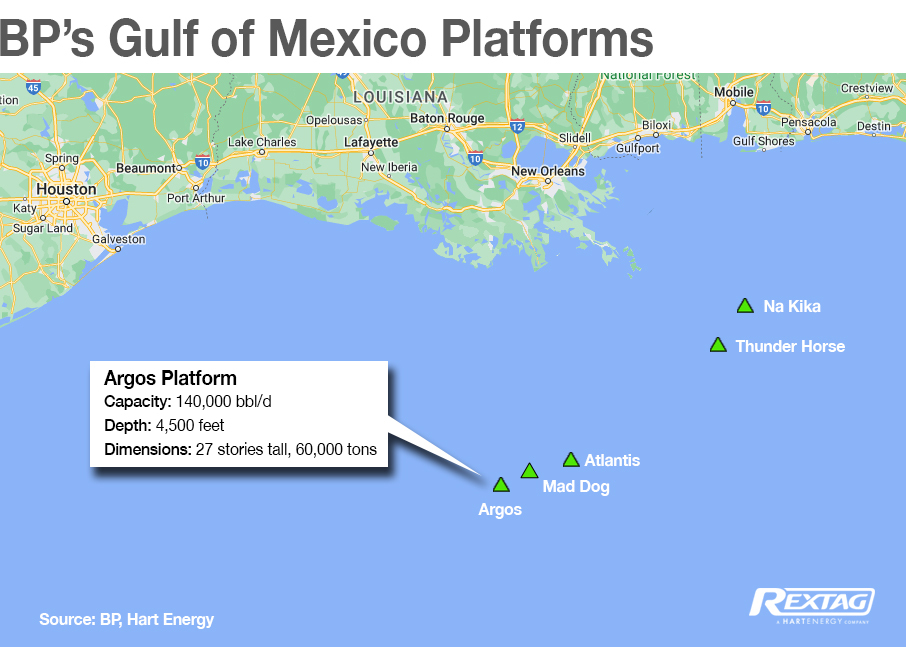

The platform — BP’s fifth platform in the GoM — has a nameplate capacity of 140,000 bbl/d of oil from up to 14 production wells and water injection capacity of 140,000 bbl/d through eight injectors. So far, 11 production and four water injection wells have been drilled. The platform is moored in 4,500 ft water depth about 190 miles south of New Orleans in Green Canyon Block 780.

“It's been an incredible journey,” said Ruthven, who’s been on the “massive legacy project” for over 10 years.

Ramping up

Currently, Sykes said, BP is ramping up the first well producing to Argos.

“We'll continue to ramp up additional wells over the year until we get to plateau production,” she said. “Our focus is really to do it safely” in a controlled way. “We'd rather start up, then stay up than have other operational challenges.”

She said that caution makes sense because of the high value of the wells and the operator’s learnings from years of operating in the deepwater.

She said the semi-submersible platform will increase the supermajor’s gross operated production capacity in the GoM by about 20% as it ramps up production throughout the year. BP’s other operated production platforms in the GoM include Thunder Horse, Atlantis, Mad Dog and Na Kika.

Sykes said BP’s focus in the Gulf of Mexico revolves around producing “resilient hydrocarbons” or those that are high-margin and low-carbon intensity barrels.

“Our strategy is very much to take care of those hubs, keep them full and then find and discover new hubs,” she said.

As such, the supermajor is focused on further development around those existing GoM deepwater production facilities. BP was one of the top bidders in Gulf of Mexico Lease Sale 259 and “looked to shore up our positions around our hubs,” Sykes said.

Waterflooding and futureproofing

Argos is using BP’s LoSal Enhanced Oil Recovery (EOR) with a waterflood injection capacity of more than 140,000 bbl/d of low-salinity water to help increase oil recovery from the Mad Dog field.

“In this field, about 50% of the reserves come from water injection,” Ruthven said.

Sykes called Mad Dog a massive resource.

“It's very early in its production life,” she said, adding that with 5 Bboe of oil in place, “we’ve got a long way to go before we're anywhere near the recovery factor.”

She said, “it wouldn’t surprise me” if BP pursued a third phase to the Mad Dog Field, based on the company’s approach at other large developments.

“You can look at the number of phases on our other fields to kind of infer what's likely in these big developments,” she said, citing additional phases of Atlantis and Thunder Horse and additional tie-ins to Na Kika. “That is definitely part of our strategy.”

Ruthven said the Argos semi design takes that into consideration.

“We designed it with a future in mind. It has capacity for additional water injection. It has facilities for further tiebacks to it and tie-ins,” he said.

Digital advances

The operator called Argos its most digitally advanced platform operating in the Gulf of Mexico. It uses BP’s and Dynamic Digital Twin technology. The Dynamic Digital Twin, a BP patent-pending software that links complex data from Argos to 3D digital models of those systems, allowing remote operators wearing virtual reality (VR) headsets to access data in real time to improve decision making, efficiency and safety.

Ruthven said the Dynamic Digital Twin takes 3D models from the design and engineering phases and combines it with other BP databases.

“Coupled with a photogrammetry survey of the platform, effectively, you can sit in the office and an engineer, an operator can go and visualize exactly how every single item is down to the fine detail, down coating on the pipe,” Ruthven said. “That allows the folks on the onshore side of things to plan their work, to look at how we're going to do maintenance, corrosion monitoring, all those other things.”

When coupled with a Microsoft HoloLens, “you can actually go in and actually physically walk around the facility” in VR, he added.

While the technology was used in the development phase, the expectation is it will be used mostly during operations to help reduce the need for offshore trips to survey and troubleshoot issues.

BP operates the Mad Dog Field with 60.5% interest on behalf of Woodside Energy with 23.9% and Chevron affiliate Union Oil Company of California with 15.6%.

Recommended Reading

Chevron, Brightmark JV Opens RNG Facility in Arizona

2024-04-10 - Eloy RNG produces RNG using anaerobic digesters at the Caballero Dairy in Arizona, Brightmark said April 10.

One Man's Trash? Treasure of RNG Prospects Available for Waste Facilities

2024-02-21 - About 4.4% of current U.S. fossil gas demand could be displaced by RNG from waste, a new Deloitte report shows.

Tangled Up in Blue: Few Developers Take FID on Hydrogen Projects

2024-04-03 - SLB, Linde and Energy Impact Partners discuss hydrogen’s future and the role natural gas will play in producing it.

Energy Transition in Motion (Week of April 5, 2024)

2024-04-05 - Here is a look at some of this week’s renewable energy news, including the U.S. Environmental Protection Agency’s $20 billion ‘green bank.’

Energy Transition in Motion (Week of Feb. 23, 2024)

2024-02-23 - Here is a look at some of this week’s renewable energy news, including approval of the construction and operations plan for Empire Wind offshore New York.