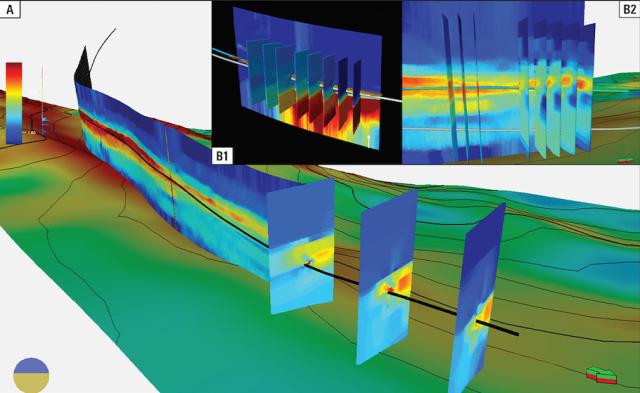

The larger image shows integrating a 1D longitudinal resistivity inversion and a 2D transverse resistivity inversion map in the 3D steering workflow. This enables locating the sweet spot and adjusting trajectory, while inset B1 shows the 2D real-time transverse resistivity inversions enabling mapping reservoir tops in the well landing section. Inset B2 is the advanced lateral inversions that provide complete 3D structural understanding of the reservoir while drilling. (Source: Schlumberger)

Schlumberger has introduced the GeoSphere 360* 3D reservoir mapping-while-drilling service at the International Petroleum Technology Conference (IPTC) on Feb. 22. The service leverages advanced cloud and digital solutions to deliver real-time 3D profiling of reservoir objects. This improves reservoir understanding and enhances well placement to maximize returns from complex reservoirs.

“GeoSphere 360 service is the pinnacle of reservoir mapping while drilling and the first in a series of digitally enabled technologies and services that we will bring to market this year,” Jesus Lamas, Schlumberger’s president of well construction, said. “Unlike conventional technologies, 3D reservoir mapping while drilling identifies fluid bodies and faults—at a volumetric reservoir scale—which is unique in the industry. This is a transformative digital capability that drives improved reservoir understanding, optimized well placement, increased reserves bookings and production per well, and enhanced field-development decision making. Our customers can place fewer, higher-quality wells with greater certainty and confidence, improving returns from complex reservoirs and reducing the carbon intensity of field development.”

Geomodeling at the reservoir scale delivers 3D characterization of structural, stratigraphic and lithographic features of the reservoir, which increases geosteering confidence. The GeoSphere 360 service uses a unique combination of advanced cloud and computing solutions and digitally enabled hardware to acquire 3D electromagnetic data. This data is contextualized in real time to improve the understanding of resistive reservoir bodies and reservoir dynamics, contributing to better field development planning.

The GeoSphere 360 service has undergone extensive field testing in various environments globally. In the Middle East, an operator leveraged the GeoSphere 360 service for real-time 3D mapping of sand channel bodies, resulting in optimal well placement and maximum reservoir exposure.

In North America, an operator used the 3D reservoir mapping-while-drilling service to characterize structural and stratigraphic features of a reservoir, providing seismic scale understanding that led to optimized field development planning. A North Sea operator used the GeoSphere 360 service to integrate data from multiple scales of measurements, enabling strategic geosteering decisions that helped reduce uncertainties, maximize well placement and optimize production potential.

Recommended Reading

Talos Energy Expands Leadership Team After $1.29B QuarterNorth Deal

2024-04-25 - Talos Energy President and CEO Tim Duncan said the company has expanded its leadership team as the company integrates its QuarterNorth Energy acquisition.

Energy Transfer Ups Quarterly Cash Distribution

2024-04-25 - Energy Transfer will increase its dividend by about 3%.

ProPetro Ups Share Repurchases by $100MM

2024-04-25 - ProPetro Holding Corp. is increasing its share repurchase program to a total of $200 million of common shares.

Baker Hughes Hikes Quarterly Dividend

2024-04-25 - Baker Hughes Co. increased its quarterly dividend by 11% year-over-year.

Weatherford M&A Efforts Focused on Integration, Not Scale

2024-04-25 - Services company Weatherford International executives are focused on making deals that, regardless of size or scale, can be integrated into the business, President and CEO Girish Saligram said.