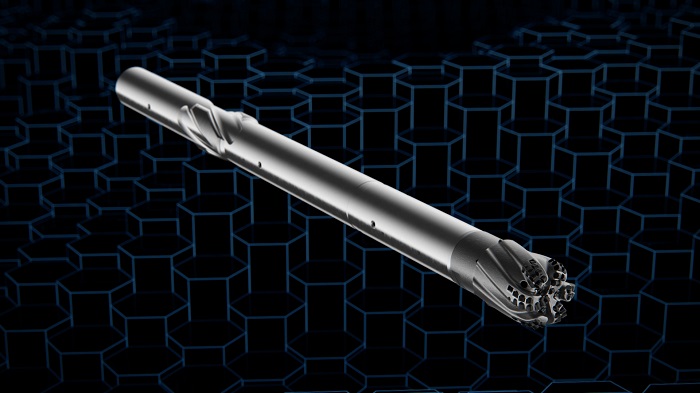

Bernoulli's principle of fluid dynamics, illustrated on the SABER tool is used to steer drill bits downhole. (Source: Enteq Technologies)

The same physics that keeps airplanes aloft in the sky can be used to steer drill bits.

Shell discovered the possibility years ago. Enteq Technologies later licensed the technology and developed it into a modular rotary steerable system that directs the bottomhole assembly (BHA) from the base of the drill bit. Recently, the Steer-At-Bit Enteq Rotary (SABER) tool completed downhole drilling testing at the Catoosa Drill Test Facility in Oklahoma.

Enteq CEO Andrew Law said it’s been a quarter of a century since rotary steerable systems (RSSs) displaced mud motors as the directional drilling tool of choice, with incremental improvements in the following years.

Most of the RSSs are point-the-bit, which changes direction by bending the main shaft running through the bit; or push-the-bit, which uses pads on the outside of the tool to press into the wellbore and change direction.

“Ultimately the fundamental approach has remained unchanged,” Law said.

Enteq’s SABER tool uses fluid forces at the base of the bit to create side steering, he said.

“Every other rotary steerable system uses pads or pistons or a mechanical form of steering,” he told Hart Energy.

The SABER tool creates and controls a system of high-velocity fluid flow and low-velocity fluid flow, which in turn creates low-pressure and high-pressure zones. The fluid forces can then change the direction of the drill bit, he said.

The tool is based on a fluid dynamics concept Swiss mathematician and physicist Daniel Bernoulli published in the 1700s. Bernoulli’s principle states that the pressure in a fluid decreases as its velocity increases, according to Britannica. It is, at its heart, the principle that keeps airplanes in the air.

The shape of a wing “creates a low-pressure zone on the top of the wing and then the wing lifts. What we are using is exactly the same principle, but we are doing it in a different environment,” Law said.

Early breakthrough

During drilling testing years ago, Shell discovered a plugged nozzle in a drill bit created differential pressure that would lift up a block of rock. Following an investigation into the anomaly, Shell carried out a proof of concept on the possibility of using imbalances in pressure as a means of steering a drill bit, Law said.

Enteq later bought the rights to the technology from Shell, carried out additional development and tested the resulting SABER tool in Norway and Oklahoma to prove it could handle directional drilling challenges.

Some are skeptical about the approach.

“People just don't believe that you can get enough side force from using the Bernoulli principle to steer,” he said. “We've created a field-ready commercial prototype of the tool that has proven that this system can work.”

Field testing in Oklahoma was carried out in July following testing in Norway earlier in the year.

In the field, “Nobody's written the rule book on this before, and nobody's written the operations manual. So you are writing the operations manual as you're going along. It's a bit like trying to fly a helicopter and then writing the instructions whilst they're trying to fly the helicopter for the first time,” he said.

During testing, the SABER tool performed as expected in typical reservoir rock conditions, he said.

“We generated a build. We dropped when we needed to. We held azimuth when we needed to, and we turned. We changed azimuth when we needed to,” Law said.

The design is modular and has fewer moving parts than traditional rotary steering systems, he said.

“It is designed to be a rugged and low-cost system,” he said. “The main body of the tool is really robust because we don't have machined parts.”

SABER has an electrical generator, a CPU navigation unit, a drive force to provide rotational force and a bit valve cartridge that directs the fluid flow to steer the bit.

SABER is currently available as a 5-in tool for a 6 1/2 in bit size.

“It’s not quite a rotary steerable in a suitcase, but it's not far off. A rotary steerable in a large suitcase, maybe,” Law said.

Enteq estimates the tool has a total cost of ownership of up to 30% less than a traditional RSS.

Enteq is now commercializing the tool for directional drilling in the oil and gas industry. It has geothermal and methane capture applications as well, Law said.

Recommended Reading

SunPower Appoints Garzolini as Executive VP, Chief Revenue Officer

2024-03-14 - Tony Garzolini will oversee SunPower’s sales, including the direct, dealer and new homes channels, along with pricing and demand generation.

Utility, Clean Energy Company Allete to Go Private in $6.2B Deal

2024-05-06 - The Minnesota-based utility said on May 6 it agreed to be acquired by a partnership led by Canada Pension Plan Investment Board and Global Infrastructure Partners.

BP Restructures, Reduces Executive Team to 10

2024-04-18 - BP said the organizational changes will reduce duplication and reporting line complexity.

JMR Services, A-Plus P&A to Merge Companies

2024-03-05 - The combined organization will operate under JMR Services and aims to become the largest pure-play plug and abandonment company in the nation.

Chord Energy Updates Executive Leadership Team

2024-03-07 - Chord Energy announced Michael Lou, Shannon Kinney and Richard Robuck have all been promoted to executive vice president, among other positions.