Presented by:

The issue of carbon management is increasingly a priority–for the oil and gas industry as well as more broadly.

The energy transition is accelerating, bringing with it pressure to decarbonize more rapidly, but at the same time energy demand is rising and fossil fuels are still required to help meet those needs. Against this backdrop, oil and gas companies are having to strike a balance between decarbonizing and continuing to produce fossil fuels. And the more oil and gas they wish to produce over the longer term, the more important carbon management tools–particularly carbon capture and storage (CCS) and carbon capture, utilization and storage (CCUS)–will be.

“Most of the E&P companies, especially oil majors, consider CCUS a critical carbon abatement tool to fulfil respective net-zero targets,” said Yvonne Lam, head of CCS research for Rystad Energy. “And these energy companies are estimated to spend a significant part of their total capital expenditure on low-carbon business ventures over the next five to six years, including CCUS.”

Companies have different strategies for reaching their decarbonization goals, Lam noted, and therefore it is difficult to say how much CCUS will dominate their carbon management plans. She added, though, that hydrogen and CCUS feature far more heavily in E&P players’ plans than other low-carbon investments such as wind and solar.

“CCUS is definitely part of the game plan and the low-hanging fruit for oil and gas companies,” she said.

CCUS challenges

The E&P sector has been an early adopter of CCUS, both using CO₂ in EOR and sequestering it in underground reservoirs. While interest in utilization of CO₂ for EOR and other applications remains, the majority of proposed CCUS projects are aimed at permanent sequestration.

The approaches companies can take to CCUS are varied, and while some of the technology involved has been proven, other types have some way to go yet.

“CCUS is definitely part of the game plan and the low-hanging fruit for oil and gas companies.” — Yvonne Lam, head of CCS research, Rystad Energy

“There is a substantial amount of new and innovative ways in which you can capture CO₂–too numerous to discuss,” technology firm Delta CleanTech’s executive chairman, Lionel Kambeitz, told Hart Energy. “Most are what we would classify as ‘science experiments,’ as they have not yet proven to be commercially viable from a capital and/or operating point of view.”

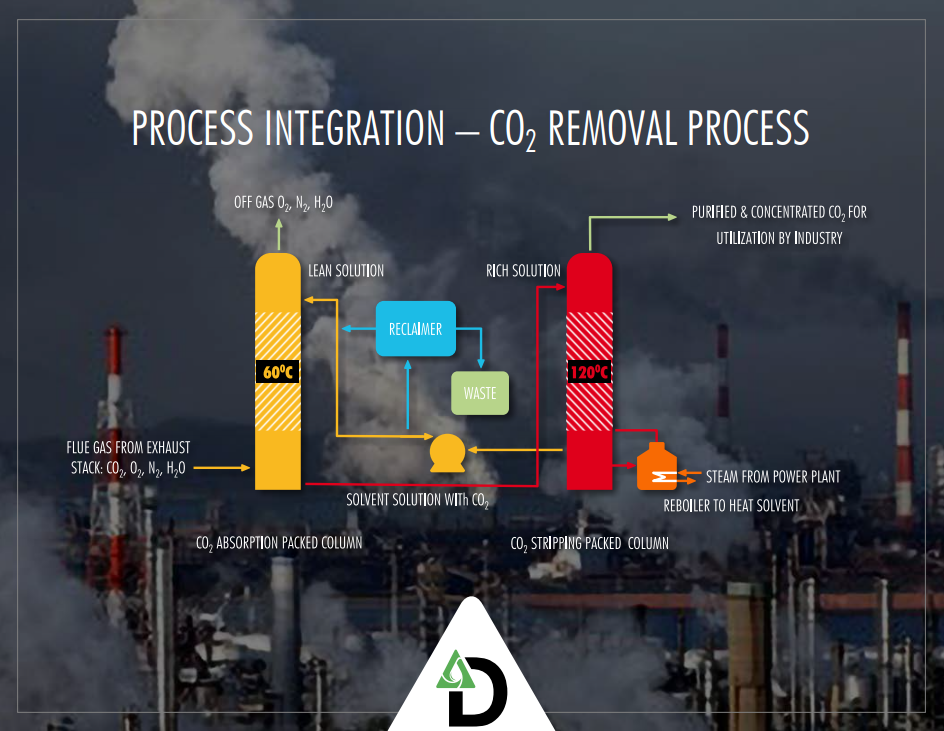

Canada-based Delta itself specializes in post-combustion CO₂ capture, among other areas relating to clean energy technology.

“Delta and three of four of its main international competitors use a variation of the post-combustion CO₂ capture process using mixed solvents,” Kambeitz said. “This is a proven technology and has been used by most of the largest CO₂ capture projects in the world to date.”

Delta’s process has become more efficient over time.

“We have taken a new CO₂ capture process–post-combustion capture using formulated solvents–and modified and improved the process,” Kambeitz said. “Like anything, if you do it enough, you can improve the process over time. We have reduced the capital costs by up to 40% and the operating costs by up to 30%.”

Large and small companies working on CCUS alike will similarly be striving to improve processes and cut costs. The growing number of players participating looks set to accelerate the technological advances that will be required to improve the economics of CCUS.

RELATED:

Where’s the Value in Carbon Management?

Capturing the Moment: Minimizing Emissions through Carbon Offsets, Capture

Lam also noted the variety of technologies that are becoming available to CCUS developers.

“There are multiple separation technologies available in the market today,” she said. “Chemical and physical absorption is the most matured and widely used technology, while others such as membrane separation, cryogenic separation, chemical looping and adsorption separation are the emerging technologies.”

Newer technologies that have yet to be proven include direct air capture (DAC), which is in the spotlight recently thanks to a DAC plant that Occidental Petroleum is developing in the Permian Basin.

“There’s definitely a long way to go for direct air capture technology, but for traditional CCS, we already have mature technology that we could use today,” Lam said. She warned, however, that even more mature technologies had a long way to go in terms of achieving the economies of scale required to meet 2050 net-zero targets.

There are various other obstacles for the oil and gas sector to overcome as well as it works to accelerate carbon capture.

“The biggest challenge currently is not how to capture the CO₂, but rather what do you do with the CO₂ once it has been captured,” Kambeitz said. Citing the example of Canada, he added that both provincial and federal governments there were taking steps to help mitigate the cost of CO₂ capture as well as trying to provide commercial uses for captured CO₂.

Another challenge is the, so far, underperformance of CCUS facilities once they come online. A high-profile example is the CCS project serving the Chevron-led Gorgon LNG terminal in Australia. Chevron said in July 2021 that the CCS system had captured 5 MM tonnes of CO₂-equivalent since starting up in August 2019. This was about 5.2 MM tonnes short of the facility’s capture targets by that date, not helped by technical challenges that had delayed its start-up by more than two years.

The Gorgon facility’s underperformance has raised concerns over other CCUS projects failing to meet carbon capture targets.

“We do see that the capture rates for operational projects fail to meet their targets,” Lam said. “This is because companies announced their maximum capture and storage capacity to attract investment, but these capacities are subjected to multiple risks involved, such as maintenance of the plant, technical failure or unexpected problems from wells in the case of the Gorgon project in Australia).” According to Lam, Rystad generally expects CCUS facilities to have 70% to 80% capture rates rather than the 90% to 95% that companies announce.

Survival of the fittest

Not all companies will be able to overcome these and other challenges. Many of the new projects announced in the past couple of years have had few details worked out thus far. As a result, it cannot be ruled out that they will ultimately be found to be uneconomic.

“In general, we assume that 30% of the announced commercial projects will not move ahead as planned, but cluster projects (large-scale CCS hubs) have a higher chance of moving forward because of government support in building infrastructure, as well as getting the necessary permits for CO₂ storage,” Lam said.

Oil and gas companies are mainly involved in the transportation and storage side of such hubs, she noted. And while the CO₂ could come from oil and gas operations, there are also initiatives underway in which E&P players are proposing to sequester CO₂ on behalf of other industrial emitters.

Last year, more than 50% of the projects announced were cluster projects, according to Lam.

“For cluster projects involving emitters with lower margins, the incentives or investments they could receive will determine if the project will move ahead,” she said.

Regions that are being targeted to be potential CCUS hubs include Canada’s oil sands and the U.S. Gulf Coast, and there are also several separate hub developments underway in Europe. These developments are being spurred in part by favorable local policies, according to Lam, who said Rystad also sees significant potential for the Middle East and Southeast Asia to become major CCUS hubs thanks to their storage potential in saline aquifers.

Inpex’s plans

One of the hub proposals currently being advanced would take place in Darwin, in Australia’s Northern Territory. The Commonwealth Scientific and Industrial Research Organisation (CSIRO), a government organization, will lead a consortium that also includes the Northern Territory state government and several energy companies to develop the business case assessing the viability of a Darwin CCUS hub.

Japan’s Inpex, Italy’s Eni and Australian firms Woodside, Santos, Origin Energy and Xodus Group have all committed to collaborating on the business case.

“The hub concept is not a single project; it offers the potential to develop a series of linked investments forming a multi-industry low-emissions CCUS hub,” an Inpex spokesperson told Hart Energy.

Inpex is the operator of the Ichthys LNG terminal near Darwin, where it is planning to build a CCS facility. Under the company’s Vision@2022 plan, unveiled in February, it will launch CCS at Ichthys in the late 2020s, initially injecting 2 MM tonnes per year of CO₂ through the project.

“Much work has already been carried out to evaluate options for geo-sequestering CO₂ emissions from the Inpex-operated Ichthys LNG project. Ichthys LNG’s onshore facilities feature dedicated plot space and tie-in points for future CCS facilities,” the spokesperson said. “For disposal, we believe the Petrel sub-basin, in the southeast portion of the Bonaparte Basin offshore northern Australia, has great potential as a storage aquifer.”

Inpex is working to bring its Scope 1 and 2 emissions down to net-zero by 2050. Under the Vision@2022 plan, the company will operate five “net-zero businesses” alongside its core oil and gas business.

“The five net-zero businesses include hydrogen/ammonia, CCUS, renewable energy, methanation and forest conservation,” the spokesperson said, adding that these were not necessarily listed in order of priority.

Within the CCUS business, Inpex is targeting CO₂ injection volumes of at least 2.5 MMtonne/year in 2030 and promoting technical development and commercialization of relevant technologies.

“Key initiatives include a CO₂ EOR demonstration project in Niigata, Japan, a CO₂ EOR scale-up in Abu Dhabi in the UAE and CCS implementation” at Ichthys, the Inpex spokesperson said. Indonesia is another country where the company is collaborating on CCS development.

Inpex anticipates a need to study and improve both the technology and economics involved in CCUS in order to facilitate its large-scale development.

“There is a substantial amount of new and innovative ways in which you can capture CO₂–too numerous to discuss. Most are what we would classify as ‘science experiments.’” — Lionel Kambeitz, executive chairman, Delta CleanTech

“From a technological standpoint, challenges include developing technologies to evaluate reservoirs suited to CO₂ storage and reduce operational costs,” the spokesperson said. “From an economic standpoint, the challenge lies in mapping economic projections. This is due to the high degree of uncertainty resulting from the various necessary steps involved in developing large-scale CCS, including conducting research and development and demonstration tests, and developing supply chains.”

The spokesperson also noted that there could be regulatory challenges, citing Japan, where CCS developers currently “lack an environment conducive to business expansion.” This could be remedied, however, by a “comprehensive regulatory system facilitating subsurface permit acquisitions, and policy support in the form of subsidies or tax incentives.” the spokesperson added.

Canadian alliance

Inpex is far from alone when it comes to calling for government support for CCUS initiatives. Similar calls have been made by oil and gas companies globally as they unveil increasingly ambitious project proposals.

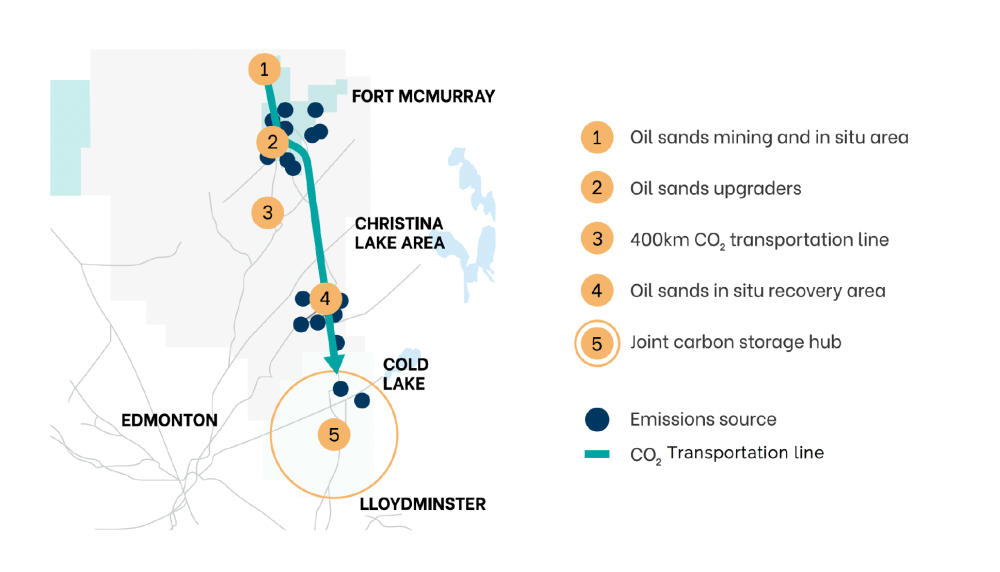

In Canada’s oil sands–another region where a major CCUS hub is under development–a group of leading producers is also counting on government support to help realize its carbon capture plans.

The Oil Sands Pathways to Net Zero Alliance, formed in 2021, comprises Suncor Energy, Cenovus Energy, Imperial Oil, Canadian Natural Resources, MEG Energy and ConocoPhillips. Together, they account for around 95% of Canada’s oil sands production.

The alliance is targeting net-zero emissions from the companies’ combined oil sands operations by 2050, and CCUS is expected to play a key role in achieving this.

“The foundational project of the Pathways Alliance is a carbon capture network,” Pathways Alliance spokesperson Alain Moore told Hart Energy. “At the heart of the network is a proposed carbon transportation line to gather captured CO₂ from more than 20 oil sands facilities (more than 10 initially) and move it to a proposed hub in the Cold Lake area of Alberta for storage.”

Members of the alliance would be both co-investors in the pipeline and hub and its customers, and the line is also expected to be available to other industries in the region interested in capturing and storing their CO₂.

“Because of the amount of capital investment required to build carbon capture and storage infrastructure, the countries that are doing this successfully are all using a collaborative model where governments are providing financial support alongside industry, which range from covering two-thirds to three-quarters of capital costs,” Moore said. “Governments in Canada understand this, and we’re working with them to find a similar made-in-Canada approach to meet our climate goals.”

The alliance has welcomed federal plans for an investment tax credit for CCUS, though the government has yet to decide how much it will be willing to offer to the industry. Moore added that in addition to such incentives, it was also essential for governments to develop enabling policies, fiscal programs and regulations that provide certainty for investors.

“For example, guarantees for availability of carbon sequestration rights, emissions reduction compliance credits and ongoing investment tax credits” could be among these, Moore said.

The oil sands region is already home to operational CCUS infrastructure, and the alliance is confident that these projects–and others under construction in Europe– bode well for building more such CCUS capacity.

“The proposed Pathways carbon capture network is similar to large carbon capture projects already underway in other progressive oil producing nations such as Norway and the Netherlands, where industry and government are working together to reduce CO₂ emissions from industry,” Moore said. “Canada and Alberta also have demonstrated technological prowess for CCUS with both the existing Quest project and the Carbon Trunk Line. So, we are confident current and emerging technologies can get the job done.”

Moore noted that Pathways companies may also have different carbon streams relating to operations beyond the scope of the alliance. Within the alliance, though, a team effort will be required.

“Much like when the Canadian Oil Sands Innovation Alliance was founded 10 years ago, it is vital that we continue to share technologies and best practices that will allow us all to accelerate the pace of improvement in emissions reduction,” Moore said.

Looking ahead

Such collaboration among industry players and other stakeholders will be vital to help scale CCUS.

“By collaborating with other companies, they will not only leverage their existing skills, they will also help share the risk in developing these projects,” said Rystad’s Lam. She cited the Gulf Coast as an example of another region where this is happening. She also sees potential for more partnerships where oil and gas companies sequester CO₂ for other industrial emitters, which do not have expertise with the transport and storage of their emissions.

“Opening up CO₂ storage for other players will definitely help to push up the success rate and deployment of CCS projects,” Lam said.

In the longer term, she sees DAC as “crucial” if the Paris Agreement goal of limiting the increase in global temperatures to 1.5 C is to be met.

“We will definitely need to rely on oil and gas this decade,” Lam said. “Despite the rapid deployment of renewables, it is still not enough to cope up with global energy demand.”

In this scenario, “it is certainly better for the companies to include CCS for new oil and gas projects, whose CO₂ would otherwise be vented,” Lam said.

Rystad recently announced that it expects service sector spending on CCUS to quadruple between 2022 and 2025, topping $50 billion on a cumulative basis over that period. But Lam said that the consultancy anticipates the share of CCUS used by the oil and gas industry to taper off from 2035, while emerging technologies such as DAC take up an increasing share from that point. This, however, is still a long way off.

Recommended Reading

BP’s Kate Thomson Promoted to CFO, Joins Board

2024-02-05 - Before becoming BP’s interim CFO in September 2023, Kate Thomson served as senior vice president of finance for production and operations.

Magnolia Oil & Gas Hikes Quarterly Cash Dividend by 13%

2024-02-05 - Magnolia’s dividend will rise 13% to $0.13 per share, the company said.

TPG Adds Lebovitz as Head of Infrastructure for Climate Investing Platform

2024-02-07 - TPG Rise Climate was launched in 2021 to make investments across asset classes in climate solutions globally.

Air Products Sees $15B Hydrogen, Energy Transition Project Backlog

2024-02-07 - Pennsylvania-headquartered Air Products has eight hydrogen projects underway and is targeting an IRR of more than 10%.

HighPeak Energy Authorizes First Share Buyback Since Founding

2024-02-06 - Along with a $75 million share repurchase program, Midland Basin operator HighPeak Energy’s board also increased its quarterly dividend.