(Source: Shutterstock)

A new digital offering that automates drilling operations is improving ROP in onshore wells.

Dubbed Predictive Drilling, the software is the first offering from a partnership between Nabors Industries and Corva. It was commercialized in August and combines Nabors’ universal rig controls and automation platforms – SmartROS and RigCLOUD – and Corva’s previously-developed artificial intelligence (AI) and control tool.

The control tool was originally used only in an advisory capacity, said William Fox, Corva’s general manager for predictive drilling solutions. The tool provided information but lacked control capability. It was often underutilized due to driller distractions.

The Predictive Drilling combination boosts efficiencies for both the Nabors and Corva systems.

“We found a way to close that gap and go to a closed-loop control,” Fox said. “When Predictive Drilling is enabled, the driller presses a button on their HMI [human-machine interface] and it actually starts optimizing the set points.”

This connection removes thousands of distractions per well from the driller, helping lock in efficiency gains, he added.

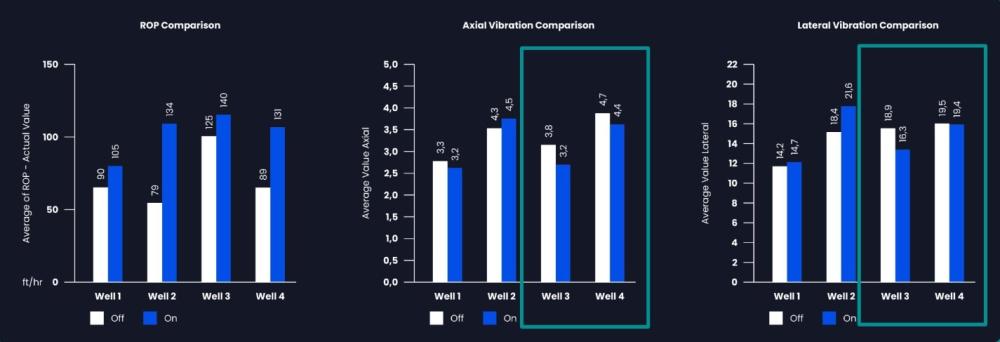

Early deployments in the Delaware Basin have delivered ROP improvements of about 36% and a reduction in average vibrations of 9.7%. The latter was achieved through use of the system’s vibration filter.

Already-existing Nabors systems feed data into Predictive Drilling.

“We use the clean data from Nabors and customer systems to run the Predictive Drilling AI,” Fox said. “Wells drilled using the partnership systems will result in much higher quality datasets that will enable them to run the other analytical tools more efficiently in formation reserve valuation.”

Knowledge is power

Fox said some of the most important data channels the system monitors in its real-time well-site information transfer standard markup language (WITSML) feed are depths, current setpoint and lateral and axial vibrations from the downhole tools. The tool also incorporates outside information such as survey data, fluid reports and existing details on which settings were successful in offset wells.

The tool continually evaluates the most recent 250 ft drilled to determine the level of success. With that data, Fox said, “it’s simulating those conditions and limits, what would be the optimal RPM, weight on bit, and differential pressure setpoints to drive the optimal ROP.”

The Predictive Drilling program’s default setpoint weights are: 70% increasing ROP; 20% decreasing mechanical specific energy; and 10% decreasing rotational energy.

“That’s the current recipe,” Fox said, but the numbers are configurable. It runs continuously on the cloud, requiring internet connectivity.

The 85% rule

No matter how “smart” the AI, human intervention is still required for certain situations. Tatiana Borges, senior product development manager for Nabors, said AI can run as much as 85% of the time, working around planned shutoffs for certain procedures — a level she is learning to accept.

“Eighty-five percent is my new 100,” she said.

Borges and Fox anticipate several significant benefits for drillers. To Borges, faster ROP means a quicker start for production, and the reduced drilling time checks an ESG box by reducing emissions.

But, Fox said, it’s not just about getting a record-setting ROP.

Success “means we can’t break the tools, so we’ve also added vibration filters. We’ve added stick/slip filters and so on to try to get the fastest, safest and smoothest ROP,” he said.

Benefits extend into production long after the well is complete, Fox added. Digitizing the entire process means “you get an absolutely top-notch record of exactly what happened during the well-construction process. That is something that is very valuable for production over the next 10-20 years.”

Because the entire process is on the cloud, Borges said, production team members can watch progress themselves and give input about how drillers can accommodate production needs while the bit is still in the hole.

One concern about any new system is the learning curve, Borges said.

“Simplicity versus speed was a careful consideration in the development process,” she said. “We built upon a familiar solution that was already in the field. We assured that a perfect blend of user-friendliness and enhanced performance would be available right away.”

These changes would impact drillers, she said, so “we always try to make their life easier and avoid changing their workflows.” She estimates training time for Predictive Drilling at about one hour.

In the field

Nabors Industries and Corva announced their strategic partnership in April, saying they aimed to create a “digital and automation offering” for the drilling industry.

A month later, they were testing their first offering in the field.

The goal of the collaboration was to spark a “paradigm shift away from relying only on human intervention and toward data-driven decision making and automated execution,” Borges said.

Fox added that “the greatest immediate effect of Predictive Drilling is to consistently deliver the lowest cost-per-foot drilled, while still being consistent, efficient and predictable.”

The focus, he said, is on helping “customers take their 75th percentile well today and turn it into their 50th percentile well in the future.”

In May, a four-well test in the Delaware Basin showed ROP gains and vibration reductions. It also showed that unplanned downhole trips could be eliminated and bit wear could be reduced. The latter, combined with faster drilling, saved the producer an estimated $50,000 to $100,000 per well.

The future is predictive

Predictive Drilling’s current version is focused onshore, but the companies expect to develop an offshore version. They also see the tool laying the foundation to integrate other sets of products the two companies offer.

With only a few wells drilled by Predictive Drilling 1.0, Fox said a second version is already being developed, incorporating feedback from initial tests. Version 2.0 will include a predictive key performance indicator (KPI) app comparing the predictive AI’s performance to results absent the Predictive Drilling software, he said.

As the AI collects and processes more data, Borges and Fox also expect that information to inform predictive alerts that anticipate certain drilling dysfunctions. That will allow the human crew to take proactive steps to prevent a failure.

“We see a promising trajectory in integrating all the Corva dysfunctions into some proactive automated mitigation, adding to what we already have in there,” Borges said.

Recommended Reading

Marketed: Wylease AFE Asset Packages in Johnson County, Wyoming

2024-04-29 - Wylease LLC has retained EnergyNet for the sale of three Niobrara Shale AFE (authorization for expenditure) packages in Johnson County, Wyoming.

M&A Spotlight Shifts from Permian to Bakken, Marcellus

2024-04-29 - Potential deals-in-waiting include the Bakken’s Grayson Mill Energy, EQT's remaining non-operated Marcellus portfolio and some Shell and BP assets in the Haynesville, Rystad said.

C-NLOPB Issues Call for Bids in Eastern Newfoundland

2024-04-29 - Winners of the Call for Bids No. NL24-CFB01 will be selected based on the highest total of money the bidder commits to spend on exploration of a parcel during the first six years of a nine-year license.

Tivoli Midstream Buys Southeast Texas Coast Infrastructure

2024-04-29 - Tivoli Midstream acquired the Chocolate Bayou from Ascend Performance Materials, including storage and land for development.

Phoenix Capital Group Acquires Uinta Basin Royalty Interests

2024-04-29 - Phoenix Capital Group’s acquisition of 1,500 net royalty acres in Duchesne County, Utah, brings the company's investment in the Uinta Basin to more than $60 million, the company said.