The Montney shale in western Canada is an unconventional tight gas shale distributed over an area extending from north-central Alberta to the northwest of Fort St. John in British Columbia. Somewhat comparable to the Texas' Eagle Ford shale, the Montney also appears to have distinct dry gas, wet gas and oil development areas. The play is a well-pressured mixture of sandstones and shale in its eastern sections while the rock characteristics become more like those of a traditional shale play as it moves from Alberta northwest into British Columbia.

The Montney formation is primarily a natural gas play with many portions of the area providing hydrocarbon-rich natural gas and condensate. The overall play is considered by many to be world-class, with estimates ranging to 450 trillion cubic feet (Tcf) of original gas-in-place. Assuming a low-end 20% recovery potential, the 90 to 140 Tcf potential places the Montney as one of North America's largest natural gas resources.

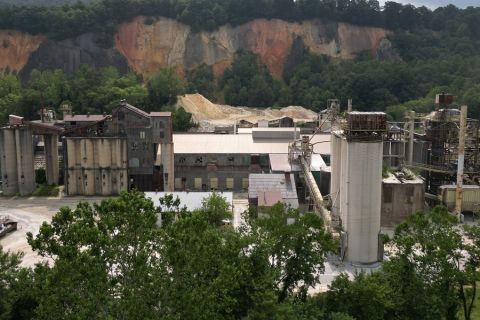

ARC Energy Trust drilled the first horizontal well in the Montney shale in 2005, and pictured here is the first gas plant it built. Source: Arc Energy Trust

At current North American natural gas prices, most of the near-term development is focused on the richer gas portions of the play because liquids price-uplift is required to support overall development economics.

The oil-rich portion of the Montney play has not been thoroughly exploited as yet, but recent activity indicates the Montney Doig sector is an area of interest. With significant demand for condensate to be used for diluent in oil sands operations, Montney area condensate is gathered and routed to the Fort Saskatchewan area via a combination of truck and pipeline. Indications are that diluent demand will double with ongoing oil-sands growth.

Strategic partnerships

Several key upstream operators have entered into joint venture arrangements as parties put together their strategies for future development plans and timelines. Many of these ventures are focused on development of new demand markets for the Montney resource base, recognizing that gas from shale and other unconventional resources being developed in other areas in North America may be sufficient to meet expected demand.

Therefore, these new markets include the potential for liquefied natural gas (LNG) exports at proposed coastal terminals and the potential for a gas-to-liquids (GTL) plant for western Canada. For reference, a 1 billion cubic feet (Bcf) per day LNG facility requires recoverable reserves of about 8 Tcf to support a 20-year project life.

Based on conservative recoverable resource base estimates, the Montney will be able to support substantial LNG exports, assuming proper commercial arrangements are achieved. Table 1 lists the LNG export capabilities currently being considered or studied for western Canada.

Several partnerships have formed around the concept of exporting western Canadian gas resources as LNG to Asian markets. Consortium Kitimat LNG Partners—consisting of Horn River operators Apache Canada Ltd, Encana Corp., and EOG Resources Canada—is proposing to direct Horn River shale volumes to a future Kitimat, British Columbia, LNG liquefaction terminal. This terminal has received Canadian regulatory approval. Phase 1 would provide for 0.7 Bcf per day of export capability by 2015, with a second phase of equal size at a later date. Preliminary site work is under way, though the final investment decision is still pending.

Another LNG-focused consortium is focusing more on the Montney resource base. This group is led by a Shell Oil Corp. affiliate and partners Mitsubishi International, KoGas Canada Ltd. and China National Petroleum Corp. The consortium has purchased property at Kitimat for possible construction on an LNG export terminal, but the parties indicate that another option might be for a floating LNG liquefaction terminal—similar to a facility that Shell is implementing in western Australia. In support of the group's LNG efforts, the participants have entered into a number of upstream partnership arrangements.

First, Encana Corp. has entered into a strategic partnership arrangement with Mitsubishi International to provide for future resource development in the Montney's Cutbank Ridge area. The area of mutual interest will include the Dawson Saturn, Dawson Swan, Cutbank Montney, Candomin and Steeprock Doig developments. The partnership as currently structured will have access to more than 400,000 acres.

Next, Encana Corp. has also entered into an arrangement with KoGas Canada Ltd. (a subsidiary of South Korea's state-owned utility) wherein KoGas will co-invest with Encana for development of certain properties in the Horn River development area, as well as certain properties in the Montney region.

Also, Shell Canada has announced a commercial arrangement with Petro-China International, a subsidiary of China National Oil Co., for participation in upstream development of a portion of Shell's Groundbirch interests in the Montney area.

Separately, Progress Energy Resources Corp., the Montney region's largest acreage holder, and Petronas Group (Malaysia's national oil company) have joined their efforts for overall long-term development in the North Montney area. The agreement not only reflects a Montney upstream investment opportunity, but both parties have indicated a common interest in pursuing LNG export opportunities. Thus, the parties have established an LNG joint venture structure and will evaluate the feasibility of building a unique terminal for future LNG export.

In a somewhat differing strategy, Talisman Energy Inc. completed a transaction with South Africa's Sasol Ltd. for joint development in the Farrell Creek development area and, just a few months later, effected a second transaction with Sasol that provided for joint development in the Montney's Cypress A area. The initial focus is indicated to be to the Farrell Creek assets.

In addition to this upstream investment opportunity and the possibility for future LNG exports, Sasol possesses a proprietary GTL technology and is seeking commercial applications. The partners have initiated a feasibility study to determine whether or not a world-scale GTL facility might be considered for implementation in western Canada, which is another potential demand market opportunity, and which would provide additional price uplift for increasingly available rich natural gas from the Montney's various resources.

Midstream infrastructure

Because the development is occurring in a number of fields across a large geographical area, and because existing midstream infrastructure was designed and implemented to support previous conventional gas efforts, future infrastructure needs are evolving into a re-utilization of the old, enhancements to existing facilities, and unique infrastructure to support future area development.

Yet, the Montney play provides a variety of challenges for developers. Portions of the play are sour (sulfur); require treatment for higher levels of CO2; and contain condensate that must be managed.

Strict regulations regarding CO2 releases into the atmosphere are in effect in British Columbia and are becoming more restrictive in the future; thus, current infrastructure decisions must reflect those regulations.

Regional midstream infrastructure includes a number of dehydration plants, stabilization facilities, CO2 treating facilities of varying designs and technology, H2S and sulfur removal facilities, and traditional gas-processing and related natural gas liquids (NGL) facilities.

Also in the region are a number of acid-gas re-injection facilities, wherein CO2 and H2S gas are re-injected into the ground for permanent sequestration. Additional testing is progressing at various facilities in British Columbia to determine the most-effective means of permanently sequestering additional quantities of CO2, especially as related to the neighboring Horn River shale development where gas contains more than 10% CO2.

With LNG liquefaction appearing to be a chosen, long-term market, minimization of all CO2 quantities and any other impurities while the gas resides in the upstream environment will minimize the need for having to manage such at the proposed coastal liquefaction terminals.

Gas plants

A large number of the area's gas plants have historically been shallow cut (refrigeration-style) plants, meaning that their designs were focused to the heavier (than methane) NGL products. This includes C2 (ethane), C3 (propane), and C4+ (butane, pentanes plus). Ethane was often rejected and returned to the gas stream and sold as gas.

These plants utilized the technology of their day, and their recoveries were effective, if not optimal. Thus, a number of deeper cut plants—often referred to as extraction or straddle plants with additional recovery capability or newer technology—have been located further downstream where the combined gas stream can then be processed again to remove ethane and any remaining NGLs.

During the years when gas prices were higher, ethane was left in the natural gas stream and Canada's chemical industry sought other feedstock. As gas prices have come down and as ethane is increasingly available from upstream sources, removal of ethane is more desirable and western Canada's chemical industry provides necessary demand. A list of the region's various gas-processing plants and related NGL facilities is included in Table 2.

Pipelines

A number of NGL-pipeline investments are under way to accommodate the increasing liquids availability. Pembina Pipeline Corp. has been very active in the Canadian NGL business with an integrated network of existing pipelines, storage, rail and trucking facilities.

Recently, with an acquisition of certain assets from Provident Energy Ltd. Pembina is expanding its Montney area midstream operations and capabilities by integrating those facilities into its network. With implementation of its Musreau deep-cut plant, Resthaven plant and Saturn facility, Pembina will enhance its rich-gas access by more than 600 million cubic feet (MMcf) per day and up to 40,000 barrels (bbl.) of NGLs by 2014.

To accommodate such, planned expansion of its Peace Pipeline and Northern NGL pipeline will increase area NGL capability by 20,000 bbl. per day by yearend 2012, with an additional 35,000 bbl. per day yearend 2013. This provides for a total area capability of 170,000 bbl. per day. The NGLs can then be routed via Pembina's existing pipelines into the Edmonton and Fort Saskatchewan areas for fractionation or other uses.

Due to their proximity to Alliance Pipeline Canada, some operators have chosen to route a portion of their rich-gas volumes directly into Alliance. Alliance has added area facilities to increase its ability to receive volumes into its mainline pipeline from Montney area producers. Veresen is also an active gatherer into the Alliance system. Those volumes are then transported downstream to be processed as NGLs in the U.S. at the Aux Sable gas-processing facility in Channahon, Illinois.

Seeking markets

Dry residue gas service in the Montney area is provided by Spectra Energy Corp.'s BC Pipeline (formerly WestCoast Energy Inc.), a 1,750-mile natural gas-transmission pipeline that can transport 2.2 Bcf per day. The system has two designated shipping zones, the T-North system, which aggregates gas into a centralized compressor station, and the T-South system, which delivers volumes southward from that location to market destinations. Deliveries are made to southern British Columbia inland and coastal markets as well as into the Seattle area at Sumas, Washington.

For many years, an interconnection to TransCanada Corp.'s Alberta system at Gordondale provided routing of limited quantities of British Columbia gas eastward into the system. Small expansions of this export capability have occurred over the years, but limitations remained due to constraints further downstream.

In late 2010, the Alberta system was significantly expanded to accept and remove additional volumes from the developing Montney area of British Columbia via the implementation of the 36-inch diameter Groundbirch Mainline Project. This project highlights TransCanada's ability to build across provincial boundaries, as it is now under Canada's National Energy Board's jurisdiction rather than Alberta provincial regulation.

Recommended Reading

Oil and Gas Chain Reaction: E&P M&A Begets OFS Consolidation

2024-04-26 - Record-breaking E&P consolidation is rippling into oilfield services, with much more M&A on the way.

US Drillers Cut Most Oil Rigs in a Week Since November

2024-04-26 - The number of oil rigs fell by five to 506 this week, while gas rigs fell by one to 105, their lowest since December 2021.

Exxon Mobil, Chevron See Profits Fall in 1Q Earnings

2024-04-26 - Chevron and Exxon Mobil are feeling the pinch of weak energy prices, particularly natural gas, and fuels margins that have cooled in the last year.

Apollo to Buy, Take Private U.S. Silica in $1.85B Deal

2024-04-26 - Apollo will purchase U.S. Silica Holdings at a time when service companies are responding to rampant E&P consolidation by conducting their own M&A.

Marathon Oil Declares 1Q Dividend

2024-04-26 - Marathon Oil’s first quarter 2024 dividend is payable on June 10.