An installation of fiber and pressure gauges at this well in western Oklahoma led to the discovery of the sealed wellbore technique. (Source: Devon Energy)

[Editor's note: This article originally appeared in the October issue of E&P Plus. Subscribe to the digital publication here.]

The holy grail of optimizing well completions is the ability to design in real time a hydraulic fracturing operation. Slowly fading are the days of “pump and pray,” replaced in part by the technological leaps made in the collection and analysis of millions of datapoints. With these datapoints, it is now possible to recreate the subsurface to better visualize the movement of fluid, the length of fractures and more.

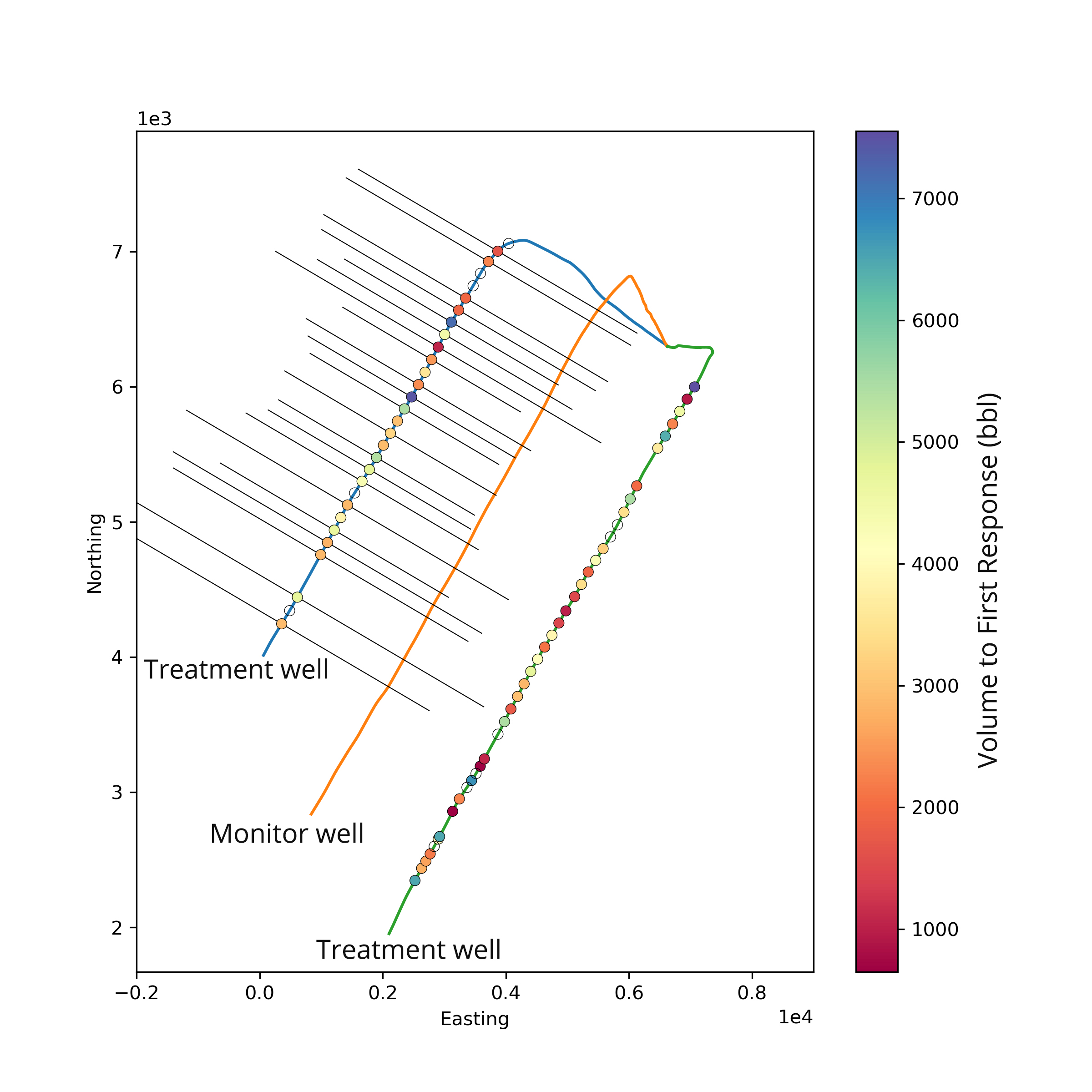

With the commercialization of sealed wellbore pressure monitoring (SWPM), completions engineers can monitor fracture growth and the fluid volumes between treated wells by tracking the pressure response in a nonperforated wellbore. As fractures approach the sealed wellbore, a pressure response is generated. Engineers are able to use the response to determine fluid volumes quickly using pressure gauges mounted at the surface.

SWPM Overhead Fracture Plot

One way to visualize it is to think of a balloon animal.

“Take the balloon and curl it 90 degrees, so it looks like a horizontal wellbore,” explained Kyle Haustveit, a senior completions engineer with Devon Energy. “When you squeeze the base of that balloon, you see the upper half expand. So if you had a pressure gauge at the end of that balloon, you’d see a pressure increase. The squeezing is the same force that a fracture from an offset wellbore applies to the sealed wellbore when it intersects the wellbore. That pressure response we see, when squeezing the balloon, is the same that our transducer sees on the wellhead when we have a fracture intersection from an offset or more than one offset wellbore.”

The sealed wellbore, in a way, is working as an antenna to transmit the pressure response to the surface.

“The small squeeze of probably less than a few centimeters of the casing string creates the pressure signal,” Haustveit said. “We amplify the pressure signal by having the sealed wellbore full of fluid, normally whatever drilling leaves in the hole, some type of freshwater or brine.”

E&P Plus recently talked with Haustveit as well as Trey Lowe, vice president of technology with Devon Energy, and Ryan Guest, director of services with Well Data Labs about the development of the SWPM and its uses at the well site.

E&P Plus: Explain how the Well Data Labs system works.

identified, we’ll work with the operator up front to make sure that we fix those.”—Ryan Guest, Well Data Labs

Guest: Our role really spans the whole process for operators that are looking to use this technique. We’ll meet with them and their associated service companies to review all the details that are required for an optimal SWPM set up, and how to do that in relation to their treatment wells, given what they’re looking to learn, whether they’re trying to understand how best to do their stage spacing and their well spacing, depending on what kind of hypothesis they’re looking at.

After that, we’ll ingest all the data and use our proprietary algorithms and machine learning to provide some detailed visualizations and analysis with regard to cluster efficiency and fracture geometry. And we’ll have our in-house completions experts provide interpretation so that it will help to guide their operators with that information on what to do with the rest of that pad within a formation. And lastly, we’ll provide all of that information back to the operators in the Well Data Labs app, as well as in Spotfire, so they can manipulate and analyze as they see fit.

E&P Plus: Where did this idea come from?

Haustveit: The birth of the sealed wellbore took a while, and it occurred in 2008. We had a large integrated diagnostic in the STACK. The diagnostics included downhole pressure gauges and permanently installed fiber-optic cable. We had six down-pressure gauges at three locations along the lateral to toe at the midsection, not the heel. At each location, we had one gauge that was ported to the inside of the casing and one ported to the outside measuring the reservoir side. We completed our fiber-optic loads last in most cases so that we can use the fiber to monitor cross-well strain. Cross-well strain is much clearer when the wellbore is uncompleted and not perforated. We watched the external gauges and we watched the strain, and we didn’t see a strong relationship between when pressure would respond on the external gauges and when strain would arrive.

It was probably a month after we completed the project that Wolfgang Deeg [completion engineering adviser] first recognized and documented these pressure responses from the gauge inside the pipe. And it’s important to note that the toe sleeve wasn’t open; there were no perforations. He was recording these pressures from the permanent downhole gauges while the wellbore was sealed. They were less than 10 psi, normally between 1 and 2 psi responses.

The team chalked it up as an interesting observation that we really didn’t know what it meant at the time. And it took another month or two before we came back to the strain. It was the first time that we had collected cross-well strain on one of our wells. When we began cross-plotting and overlaying different monitoring techniques, we overlaid the sealed wellbore pressures from the downhole gauges within the strain data. That was really the ‘aha’ moment.

E&P Plus: How is this option different from other options that are available?

Lowe: The first time that we started rolling, we really got serious about trying to understand the geometry of the fractures. I was actually an engineer at the time, and it was almost eight years ago. We spent almost a year and over $2 million installing fiber optics to listen acoustically to fractures. And since that time, we’ve continued to try to improve upon that, and we’ve used strain measurements. We’ve driven the cost down from $2 million now approaching $1 million, and what the team has discovered and basically invented through all of those processes is sealed wellbores. Now we’re talking about measuring fractured geometry, not with million-dollar numbers, but now we’re in the tens of thousands of dollars—so, orders of magnitude cheaper.

E&P Plus: How are the data and pressure readings used?

Guest: The data and pressure readings are run through our machine learning platform and algorithms, and that provides an understanding of fracture geometry and response volumes. It’s then used to gain information and test hypotheses on a pad in a formation, and it can help to inform optimal well spacing, whether wells with fewer stages will perform as efficiently as those with more. And it can predict how long fractures will remain open and help to mitigate depletion issues.

E&P Plus: Do you need the datapoints to be cleaned or quality control-checked before your analysis?

Guest: There is a thorough review and quality control process for the data we ingest. If any issues are identified, we’ll work with the operator up front to make sure that we fix those. Among the most critical steps is ensuring that we have accurate time synchronization of the various gauges, because you’ll have some that are on the monitor well, as well as gauges that are monitoring the treatment wells themselves. We want to make sure that that’s synched up, and we want to make sure that the frac parameters are clear and set and that we’re selecting the appropriate smoothing method.

E&P Plus: What made this technology possible now versus before?

Lowe: Devon has invested heavily in the tools and the processes that speed up the analysis described. When you marry that investment with tools, the engineering talent and the discoveries, they seem to be coming much faster than we’ve seen before. Specifically, several years ago we decided as a company that we were going to collect and stream all of our frac data from our well sites into our own proprietary systems. That forced us to build out the tools and the processes to have good quality data that we could do analysis around.

E&P Plus: Is there a recommended ratio between monitor wells and producing wells?

Haustveit: One monitor can monitor multiple offset wells, but to the number, the more we can get, the better. But it’s really based on the goal of the project. If it’s to be focused on a depleted area, and you’re trying to understand the asymmetry, you may only need one monitor well. If you’re trying to understand the impacts of vertical staggering and multi-vendor developments, it’s best to have a monitor in one or more benches to understand height from a treatment well up or down into a different bench. So it’s tough to put a single ratio on it.

E&P Plus: What further improvements or refinements are planned or in process?

Haustveit: The next big advancement operationally is using a zipper operation, using two wells and creating a sealed wellbore in each well as we zipper by, either setting a different type of plug or ball in place, which we normally do to set a plug, [and] we have our frac ball on top of the plug. We can pressure up on it and then create a sealed wellbore above that plug. That’s going to be a big step forward because it’s going to open the door for a lot more monitoring.

Recommended Reading

How Diversified Already Surpassed its 2030 Emissions Goals

2024-04-12 - Through Diversified Energy’s “aggressive” voluntary leak detection and repair program, the company has already hit its 2030 emission goal and is en route to 2040 targets, the company says.

BKV CEO Chris Kalnin says ‘Forgotten’ Barnett Ripe for Refracs

2024-04-02 - The Barnett Shale is “ripe for fracs” and offers opportunities to boost natural gas production to historic levels, BKV Corp. CEO and Founder Chris Kalnin said at the DUG GAS+ Conference and Expo.