The Velox wellhead system provides superior isolation between casing strings with quick-connect components so that you can lock in pressure in a flash, according to Weatherford. (Source: Weatherford International Plc)

[Editor's note: A version of this story appears in the August 2020 edition of E&P. It was originally published Aug. 3, 2020. Subscribe to the magazine here.]

New wellhead system reduces potential leak paths, enhances safety

Weatherford has released the Velox wellhead system for operators needing to lock in pressure integrity while enhancing safety and improving efficiency. Velox delivers isolation between casing strings with quickconnect components that maintain pressure control, reduce potential leak paths and minimize nonproductive time during installation in many applications, including HP/HT and sour-gas wells. The system expedites installation by enabling the pack-off to be run in a single trip from the rig floor, which removes personnel from the cellar. The system also reduces potential leak paths by eliminating conventional flange-to-flange methods and external lockdown screws. Velox also expedites installation by eliminating wait time for cement to cure, enables mandrel hanger installation from the rig floor rather than the well bay and accelerates assembly to the BOP stack with the Rapid-Lok design feature.

Updated software provides optimization of production assets

ChampionX has released XSPOC 3.0, the latest version of its production optimization software. This release provides a number of powerful updates to the XSPOC platform, enabling set-point optimization of rod lift wells and artificial intelligence (AI)-driven classifications for electric submersible pumping (ESP) wells that allow users to better optimize their production assets with fewer resources and time. The 3.0 update also includes further development of XSPOC’s physics-based diagnostics for ESP and gas-lift wells, including additional flow models and equipment specifications. This update is built on XSPOC’s optimization heritage and takes steps to enable optimized autonomous control for all methods of artificial lift.

New firing system for high-speed, multiwell, zipper frac completions

GEODynamics Inc. has released its EPIC family of integrated technologies that are designed to deliver a fast, fully integrated, addressable firing system that supports high-speed, multiwell, zipper frac completion techniques. The product release includes the EPIC Command Shooting Panel, EPIC Test Surface Tester and EPIC Switches, which offer reliable multifunctionality. The EPIC System is electronic static discharge, radiofrequency, high voltage and without a single point failure, thus intrinsically safe. EPIC Command is a highly intuitive and user-friendly shooting panel. For example, EPIC plots shot data on the touch-panel display in real time for positive shot verification and simultaneously logs the data for future performance review. The system also uses advanced technology to ensure high reliability. EPIC Command is complemented by GEODynamics’ line of EPIC Switches, which can be installed into industry-standard switch subs as an integral part of the pressure bulkhead in a slim pack flying lead design as well as the proprietary module in the company’s STRATX line of tools. EPIC Switches were designed for optimum performance using the EPIC Command system’s advanced telemetry, while also offering robust operation with Warrior software and control panels.

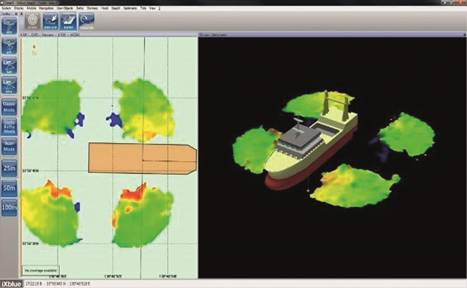

Multibeam sonar offers increased efficiency and safety

(Source: iXblue)

iXblue, a provider of navigation, subsea positioning and imagery solutions for the offshore market, has released the SeapiX-C solid-state 3D multibeam sonar. The technology offers realtime georeferenced static bathymetry capabilities to offshore operators for instant monitoring and decision-making. Offering a new static 3D imagery tool to display the seabed in real time during jackup barges deployment, SeapiX-C enables operators to directly see where they are positioning the legs of the platforms, bringing higher efficiency and safety to deployment operations by removing the need for time-consuming and costly pre-lay diver operations. All realtime bathymetric results, platform information and other critical information are displayed within a single user-friendly interface to facilitate operations.

New ball valve simplifies installation for high-flow applications

(Source: Swagelok)

Swagelok has released its GB series ball valve, a versatile fullbore, bi-directional flow-capable ball valve designed for extended operation in harsh environments at a working pressure of 6,000 psig. The Swagelok GB series ball valve is engineered to provide high flow rates at this working pressure. The valve also simplifies installation, minimizes rework requirements and delivers the reliable shutoff performance needed to keep workers safe and systems operating efficiently in a variety of demanding applications. Examples of ideal applications for the valve include use in hydraulic, injection and fire suppression systems in the oil and gas industry as well as for isolation in highly corrosive alkylation operations in the chemical and petrochemical industry. The Swagelok GB series ball valve provides value by reducing the time and cost required to install and verify the performance of components installed in high-flow industrial applications. For example, the valve is designed for quick, easy setup, with bi-directional flow eliminating concerns of backward installations. The ball valve is also engineered to provide long-term benefit to owners and operators through features, materials and design options that help protect workers and maximize component life in challenging conditions.

Gas compression engine lowers emissions and operating costs

Caterpillar Oil & Gas has released the Cat G3520J gas compression engine, which is designed for oil and gas applications to meet industry emission requirements. Its robust diesel strength design prolongs life and lowers owning and operating costs. With ratings at 1104 and 1286 bkW, the G3520J engine design is built on the reliability and durability of the Caterpillar G3500 LE series. Benefits and features of the G3520J include the ability to burn a wide range of fuels and a broad operating speed range with improved altitude capabilities. The engine also leverages Ultra Lean Burn technology. In addition, the Advanced Digital Engine Management A3 system integrates speed control, air/fuel ratio control and ignition/detonation controls.

Companies collaborate to develop solutions for optimizing reservoir management

Emerson and Quantum Reservoir Impact (QRI) have partnered to develop and market next-generation applications for artificial intelligence (AI)-based analytics and decision-making tools customized for oil and gas E&P. The partnership will help oil and gas customers embrace digital transformation technologies and harness vast amounts of data to optimize their reservoir management strategies. The collaboration combines Emerson’s independent E&P software portfolio with QRI’s industry expertise in applying augmented AI, machine learning and advanced analytics for asset and reservoir management. As part of the ongoing collaboration, the companies will apply advanced computational technologies to help geoscientists and engineers make actionable and reliable field development decisions quickly, mitigating risks and leading to higher productivity and better performance.

New VR training platform aids in dropped objects prevention

The new virtual reality (VR) platform called DROPS VR, from software firm DrillingVR and oil and gas industry safety group DROPS, is designed to drive awareness and education around dropped objects prevention in industries such as oil and gas. DROPS VR is a collaborative online program that encompasses VR training apps, exhibition areas and virtual conference spaces. Firms will be able to access new online drops prevention training tools for free via the system, aiding dissemination of HSE best practices on a global scale. The DROPS VR software enables personnel in all roles to train more effectively to identify and neutralize drops hazards on offshore assets. Best practice drops prevention technology (e.g., high-quality, corrosion-resistant steel mesh nets) can be deployed within the software. The practical application of drops prevention products in a versatile virtual environment prepares personnel for the real world where mistakes cost lives.

Editor’s note: The copy herein is compiled from press releases and product announcements from service companies and does not reflect the opinions of Hart Energy. Submit your company’s updates related to new technology products and services to Faiza Rizvi at frizvi@hartenergy.com.

Recommended Reading

Honeywell Bags Air Products’ LNG Process, Equipment Business for $1.8B

2024-07-10 - Honeywell is growing its energy transition services offerings with the acquisition of Air Products’ LNG process technology and equipment business for $1.81 billion.

TGS Awarded Ocean Bottom Node Data Acquisition Contract in North America

2024-07-17 - The six-month contract was granted by a returning client for TGS to back up the client’s seismic data capabilities for informed decision making.

ProFrac, IWS Taking the Garbage Out of Oilfield Data Transfer

2024-07-16 - ProFrac and Intelligent Wellhead Systems’ MQTT protocol promises to speed up communications at the frac site, not only by saving costs but laying the foundation for future technological innovations and efficiencies in the field, the companies tell Hart Energy.

E-wireline: NexTier Taps Oilfield Grid, Automation for Completions

2024-07-23 - NexTier Completion Solutions is using advanced electric-drive equipment, automation-enabled pump down technology and digital connectivity to optimize wellsite operations during shale completions.

How Generative AI Liberates Data to Streamline Decisions

2024-07-22 - When combined with industrial data management, generative AI can allow processes to be more effective and scalable.