Salt caverns, similar to the one shown here with lights suspended, can be used to store hydrogen. (Source: Roberto Soria/Shutterstock.com)

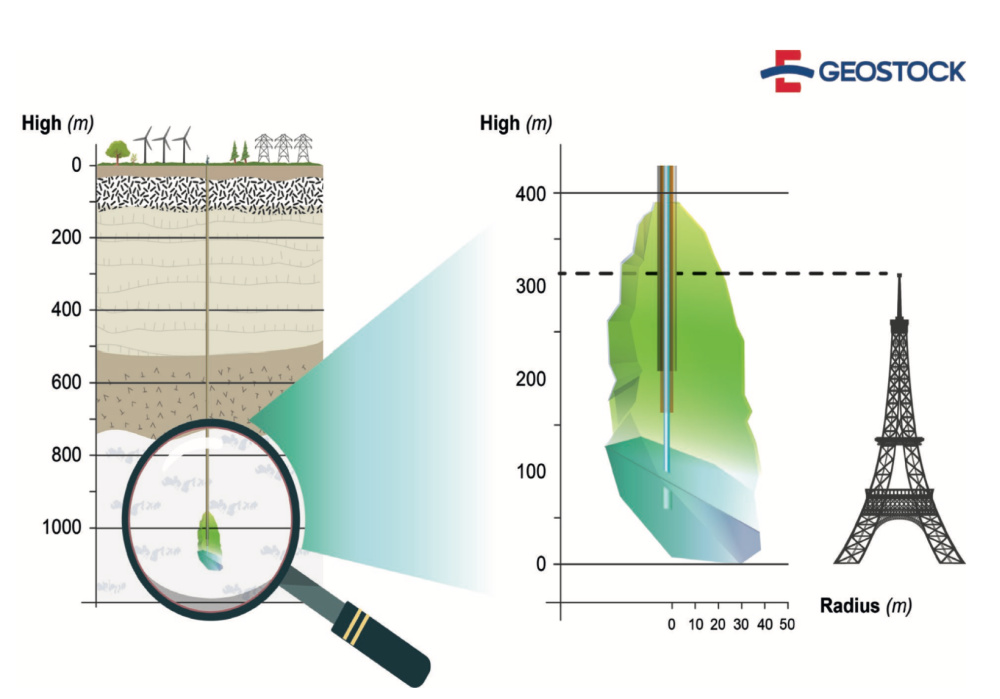

HOUSTON—At more than double the height of The Empire State building belowground, salt caverns about as tall as the Eiffel Tower are capable of storing up to about 4,000 tons of hydrogen.

“This is why you go underground,” said Claire Behar, chief commercial officer for Hy Stor Energy, the company that plans to develop what could be the United States’ largest green hydrogen hub in Mississippi. “You can really get to that scale, and it’s this availability of supply that is needed to transition off of fossil fuels to renewable hydrogen.”

Energy experts are bullish on hydrogen, touting its ability to decarbonize high CO2-emitting sectors such as steel manufacturing, maritime and heavy-duty transport where direct electrification isn’t necessarily the most cost-efficient solution.

Used today mostly in oil refining and for fertilizer production, clean-burning hydrogen—which is produced by passing electricity through water—is versatile and can serve as a fuel and for electricity generation. Pointing to data from the Road Map to a U.S. Hydrogen Economy report, Behar said hydrogen demand could hit 17 million metric tons in the U.S. by 2030 and swell to more than 60 million metric tons by 2050.

“If we’re projecting only 5% is stored underground for these hydrogen demand figures, it means that by 2030 we’re going to need over 200 salt caverns assuming 4,000 tons per cavern, and by 2050, this number is as much as 700,” Behar told attendees at a hydrogen conference in April. “Salt cavern storage is the solution. … Salt cavern storage of hydrogen is the only commercially available technology today for seasonal renewable energy storage.”

Net zero by 2050 is too far away to act, given the impacts of climate change evident today, according to Behar.

“We need to be acting today at scale and in a reliable, resilient fashion that is not intermittent and this is our focus at Hy Stor. Our lens is not 2050; our lens is 2025,” she said. “We’ve spent the past three years putting the pieces together, getting our acreage, getting our permitting, getting both local and state support so that we’ll be breaking ground with construction by the end of this year and in-service by 2025.”

Hy Stor announced in October 2021 plans to develop, produce, store and deliver green hydrogen at scale in the U.S. Working with partners Conner, Clark & Lunn Infrastructure, Hy Stor’s Mississippi Clean Hydrogen Hub—the company’s first major project—is expected to produce an estimated 110 million kg of green hydrogen annually and store more than 70 million kg of green hydrogen in its underground storage caverns. It would be one of the world’s largest.

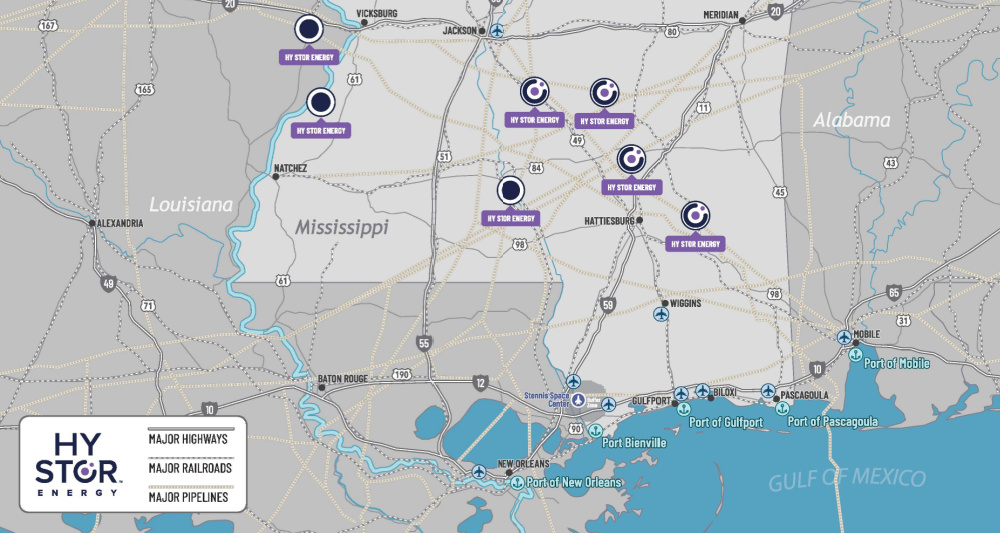

“Our footprint stretches from just outside of Jackson, approximately 200 miles all the way down to deepwater ports with access to the Port of Gulfport, Pascagoula, New Orleans, Port Mobile,” Behar said. “We have over 50,000 acres currently in our control, with four salt domes fully permitted … and three more under our control.”

The outsized acreage will give customers the ability to co-locate with the company, putting supply, demand and storage within close proximity. She called storage “the buffer that bridges the gap between supply and demand.”

Following her talk at the World Hydrogen North America conference, Behar sat down with Hart Energy to speak more about the project, hydrogen hubs and production along with challenges and opportunities facing the burgeoning sector. Her comments were edited for length and clarity.

Hart Energy: What role does hydrogen storage play in advancing global hydrogen demand and consumption?

Claire Behar: Hydrogen storage really is the core. It’s interconnecting. As they are developing all of these hubs in the United States, the storage component is really how you secure the availability of supply, and it’s connecting all of the demand centers with the supply centers.

HE: What are your thoughts on the need for hubs to focus more on demand instead of production?

CB: There are all of these announcements coming out with electrolyzer companies saying we’re going to build this much supply, but there needs to be an end user for that. A question that keeps coming up is who do we see as the first movers on the demand side. It’s really these hard-to-decarbonize sectors such as steel, maritime shipping. They know that they need to convert, and they know that the only way to convert their operations renewably is with hydrogen.

HE: Besides costs, what is the greatest challenge facing the scale-up of hydrogen production?

CB: Storage components because when we speak with customers you really can’t convert—take a steel mill for example. You can’t put in the capital cost in order to build a green steel mill if you’re not going to have that security of supply. So, these customers need a reliable 24-7 source of energy storage.

HE: Where do you see new opportunities emerging to monetize and implement clean hydrogen beyond storage?

CB: Our location in Mississippi has so much opportunity in that we have those ports—Ports of Pascagoula, Gulf Port—which are so underutilized. … These ports are like 20% utilized and we can see Mississippi and the U.S. really being a leader in decarbonization of the ports.

HE: What stage of development is Hy Stor Energy in with the Mississippi Clean Hydrogen Hub? How is the regulatory approval process coming along?

CB: We’re fully permitted for the storage of hydrogen. We have our water permit. We have our acreage. We’re good on the permitting and so our plan is to break ground on construction by the end of this year. We are applying to the federal government hydrogen hub program. We also already have capital. We’ve been working on this project for years.

HE: How quickly can the hydrogen be retrieved and transported when needed?

CB: In terms of injection and withdrawal capabilities, with salt cavern storage, it’s on demand availability. So, you can serve those hourly markets and daily markets, but then the size has the ability to also serve the long-duration markets—multiday, multiweek feasible storage—and that’s really the critical component; that resiliency.

HE: Where are you in the process of development of solar for the project?

CB: The solar is what we’re breaking ground on at the end of this year. We won’t be relying on the grid. Since we are doing it in our own sandbox, that’s how we can control first of all the cost because we’re not having to connect to the grid. It lowers your electricity cost by about 70%. When people talk about the high cost of electrolytic hydrogen, 70% of that cost is the electricity cost. If you can drive that down, that is really what gets your cost down.

HE: What type of challenges have you run into so far?

CB: Advocacy and knowledge. There is a lot of news about hydrogen, but [some people] don’t completely understand what it is. For so long, solar, wind and hydro have been getting all of the attention. I think we need to be loud and proud, advocating and championing for hydrogen. … You can store hydrogen, you can transport it; it’s available on site when you need it. That’s why hydrogen is like the final piece that links together all of the renewable sources. There is going to be a portfolio of our clean energy economy but hydrogen has a critical role to play.

Recommended Reading

Orange Basin Serves Up More Light Oil

2024-03-15 - Galp’s Mopane-2X exploration well offshore Namibia found a significant column of hydrocarbons, and the operator is assessing commerciality of the discovery.