Even though the current implementation of AI is a new frontier for the industry, it is similar to well optimization of the past, said James Meek, manager of asset optimization for Vital Energy Inc. (Source: Shutterstock)

The oil and gas sector, already reaping the benefits of automation, is on the cusp of a technological revolution, as drilling advances and AI are poised to redefine operational standards.

Industry experts delved into how both are reshaping the operational landscape of the sector during Hart Energy’s recent Executive Oil Conference and Exhibition in Midland, Texas.

At the forefront: drilling automation.

Automation delivers consistency

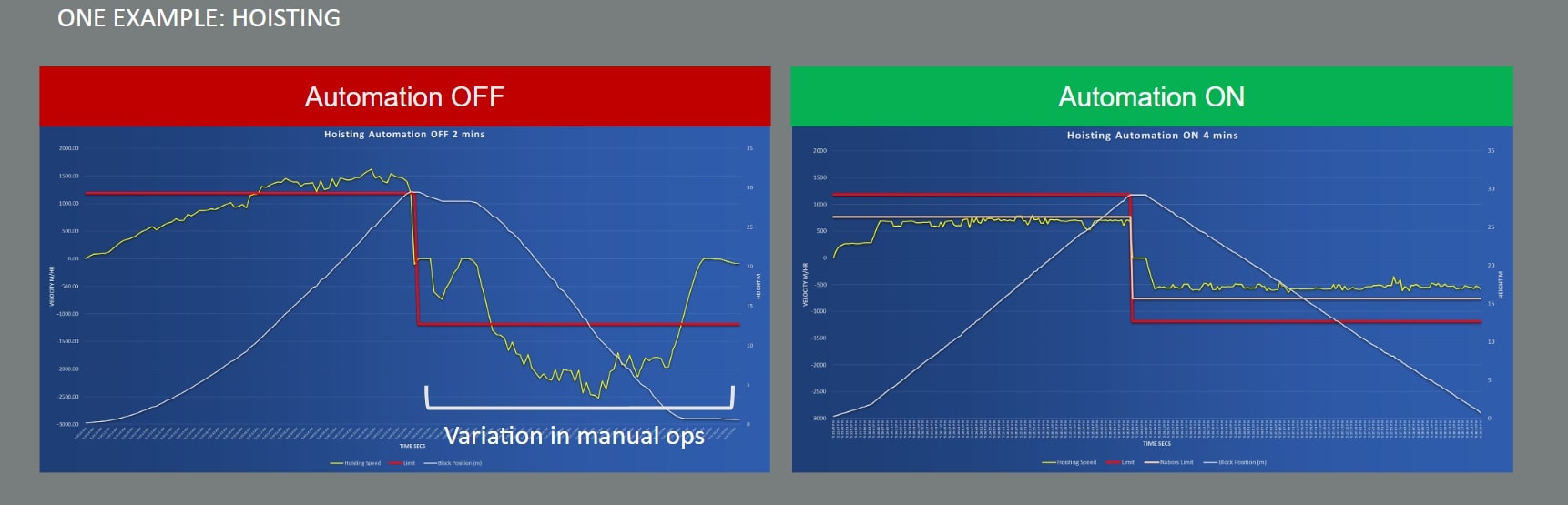

Automated drilling has the potential to improve performance, wellbore quality and well placement, said Shashi Talya, production manager of drilling automation at Halliburton — all while providing a level of consistency normally difficult to achieve through traditional methods.

“Consistency is a key word, and I think that’s where automation, AI, machine learning will help us get there,” he said during his Nov. 16 panel. Talya’s fellow panelists agreed that consistently maintaining high levels of efficiency during the drilling process is a more sustainable and achievable goal than aspiring to break records during each drilling campaign.

A study conducted by Halliburton in Norway showed just how much consistency can improve drilling operations, Talya said. While ROP increased an average of 23.4% without automation, there was a clear increase in well delivery when automated drilling was deployed. Study data collected over the course of three years also showed an increase in well placement accuracy.

"We definitely see an increase in performance... every quarter when we look at the data from the customer, we see continuous improvement," he said.

Integrating AI into rig systems also benefits the oil patch, Talya said. Collaborations with technology partners resulted in innovations, such as automated connections during drilling operations, that were part of a Halliburton project in Iraq.

During the project, Halliburton used a smart system designed by Nabors, which Talya compared to an iPhone update. “Think of it as taking your phone back to the shop and now you've got a smarter operating system, and your iPhone is now suddenly far lot more automated.”

The upgraded smart systems provided better control over critical parameters, mitigating risks during operations and improving ROP by more than 40%.

Even though the current implementation of AI is a new frontier for the industry, it is similar to well optimization of the past, said James Meek, manager of asset optimization for Vital Energy Inc.

“We have this ‘Measure, Improve, Automate’ way to think about the world, that is no different than how we've been optimizing oil and gas in the ‘20s, ‘30s, ‘40s and ‘50s,” he said. “The first thing that we did as an industry, we said ‘Is the measurement and the data we're getting accurate?’ If not, we need to automate an alert, let it call for home and create a task in an automated fashion. We have algorithms internally that do this for us. The next thing that we do as [an] industry, we try to improve the asset using current methods.”

AI slowly gaining trust

While on a familiar path as other technological improvements, oil and gas companies have shifted how they adopt some innovations, Meek said. The industry, for example, is still in an “immature space” regarding AI. And, inevitably, there are bumps along the way to maturity.

Accuracy remains a big issue for AI, and operators are still more likely to trust humans to handle the ever-changing oilfield environment.

Sammy Haroon, founder and CEO of AlphaX Decision Sciences, said AI doesn’t work like high school science equations that always arrive at the same answer given the same input.

“Physics is 100% accurate, 100% of the time – or 100% of the systems when they are completely described,” Haroon said. “I'm [in] the business of subsurface. Subsurface is a complex system… artificial intelligence is never 100% accurate or accurate 100% of the time, but it's getting closer.”

Even with inaccuracies, of which there are often few, machine learning is actually learning, due to the amount and quality of data being provided to the software, Haroon said.

Drilling performance is showing marked improvement with the infusion of automation. The industry's data innovation teams play a pivotal role, leveraging robust data architecture and demanding high quality data to elevate the accuracy and reliability of AI models.

“From the first well drilled in Texas in 1865 to Mitchell Energy's first slick water frac in 1998, technology has been the backbone [of the oil and gas industry],” Haroon said. “In the 21st century [we] have a mission to bring artificial intelligence to oil and gas, and with this mission I believe we're not [a] 25-year sector, we're not a 50-year sector. I believe artificial intelligence has the strength to make us a 200-year sector through all the capabilities that it offers.”

Recommended Reading

Exxon’s Guyana Gas Project a “Win-Win,” Set for Hook-up by Year-end ‘24

2024-04-26 - Exxon Mobil Corp. CEO Darren Woods said the company’s gas-to-power project in Guyana as a “win-win proposition particularly for the people of Guyana” when completed and hooked-up by year-end 2024.

Segrist: The LNG Pause and a Big, Dumb Question

2024-04-25 - In trying to understand the White House’s decision to pause LNG export permits and wondering if it’s just a red herring, one big, dumb question must be asked.

Texas LNG Export Plant Signs Additional Offtake Deal With EQT

2024-04-23 - Glenfarne Group LLC's proposed Texas LNG export plant in Brownsville has signed an additional tolling agreement with EQT Corp. to provide natural gas liquefaction services of an additional 1.5 mtpa over 20 years.

US Refiners to Face Tighter Heavy Spreads this Summer TPH

2024-04-22 - Tudor, Pickering, Holt and Co. (TPH) expects fairly tight heavy crude discounts in the U.S. this summer and beyond owing to lower imports of Canadian, Mexican and Venezuelan crudes.

What's Affecting Oil Prices This Week? (April 22, 2024)

2024-04-22 - Stratas Advisors predict that despite geopolitical tensions, the oil supply will not be disrupted, even with the U.S. House of Representatives inserting sanctions on Iran’s oil exports.