The North American midstream sector is on a growth trend, driven by take-away and processing demand from exploration and production companies ramping up to take advantage of increasing natural gas production, climbing oil prices and the search for value-adding natural gas liquids.

Even low gas prices are showing a silver lining as the 22-to-1 oil-to-gas price ratio drives power generators to displace coal with gas. Nearly one-fifth of U.S. coal-fired power-generation plants are set to retire during the next 10 years in response to new air, waste and water regulations, according to the January 2010 ICF International Integrated Energy Outlook Projects report.

Meanwhile, given the current apparent financial recovery, companies are expected to announce many new projects for 2011 and the next few years. Also, the Alerian MLP Index’s advance of 27.4% on a price basis and its 35.9% gain on a total-return basis in 2010 (compared to the S&P 500’s gain of 12.8%) are bringing investors back to the table.

In more good news, the Federal Energy Regulatory Commission released its five-year review of oil pipeline pricing index that will be implemented for the policy cycle of 2011 to 2015. This includes a proposed producer price index for finished goods of +2.65% for the five-year period beginning July 1, 2011. The new index represents an increase of 135 basis points, which, according to a recent report from Raymond James Equity Research, could allow liquids pipelines an upward tariff adjustment of 6.8%.

Also, despite the recent recession, it is important to note that many current projects are the result of increased natural gas production from 1998 to 2007, because pipeline construction is driven by long-term trends. During that time, gas production in the most rapidly expanding production areas of northeast Texas, Wyoming, Colorado and Utah increased 129%, while the areas’ proved reserves grew by 188%, according to data reported by the EIA.

These areas were major contributors to the 4% overall hike in gas production and the 45% rise in U.S. proved reserves. Additionally, the Marcellus shale-gas play in the Northeast and other North American unconventional gas and oil plays (see Table 1) are expected to further push new projects to move production to profitable nearby markets and realign gas flows.

Welders work to connect in-field pipelines in the growth-oriented midstream industry.

New projects: Canada

At press time, construction of an estimated 40,650 miles of new pipeline is forecast to begin in North America by 2015, compared to 27,023 miles forecast in 2010. The new estimate includes 10,346 miles in Canada and 30,296 in the U.S. Not all will come to fruition, as some projects must compete with others, and some, such as the Alaska Pipeline project, will always be built “10 years from tomorrow.” Nonetheless, the wealth of proposals on the table is evidence of growing interest in midstream-infrastructure construction.

In Canada, about 2,166 miles will move natural gas, while 986 will transport crude oil. About 811 miles will carry condensate, or light-crude oil, if the Northern Gateway Pipeline project (727 miles) and the Mitsui diluted heavy-oil pipeline (84 miles) are both completed.

Enbridge Inc.’s Northern Gateway project includes twin pipelines stretching from an east inland terminal near Bruderheim, Alberta, to a west marine terminal near Kitimat, British Columbia. One of the lines, a 36-inch-diameter pipe with initial capacity of 525,000 barrels per day, will carry crude oil westward. The other, a 20-inch-diameter line capable of moving 193,000 barrels daily, will carry condensate to the east. In June 2010, Enbridge filed its Northern Gateway application with Canada’s National Energy Board. If approved, construction will begin in 2014.

Elsewhere, the proposed 249-mile Alberta Backbone CO2 pipeline is expected to be completed in 2015, and the 311-mile Kearl to Edmonton blended bitumen pipeline could be in service as early as 2013. Other crude pipelines include Nipisi, the Christina Lake expansion and the Wood Buffalo lines, among others.

Canada’s proposed natural gas pipelines include a 110-mile Slave Lake dual pipeline, the 288-mile Pacific Trails pipeline, the 559-mile Atlantic Connector line and the Mackenzie Valley project, among others. Also on the books with a 2013 completion date is a 96-mile, Horn River shale-gas pipeline, a 149-mile refined products pipeline between Saint Laurent-Levis and Montreal, and the 188-mile Southern Lights diluents project.

New projects: U.S.

New projects scheduled to begin construction in the U.S. by 2013 surpass Canadian projects, with an estimated 8,451 miles of crude-oil lines, 15,185 miles of gas lines (including at least 4,000 miles in shale plays), 1,140 miles for CO2, 1,474 miles for ethane, 1,700 miles for ethanol and 650 miles for NGLs.

One of the more notable is the $12-billion Keystone pipeline system, which will link Canadian crude oil with refining markets in the U.S. On June 30, 2010, TransCanada began commercial operation of the first phase of the Keystone system, highlighted by the conversion from gas to crude, and construction of an innovative bullet line to carry crude nonstop from Canada to market hubs in the U.S. Midwest. Keystone Cushing (Phase II) is an extension of the Keystone system from Steele City, Nebraska, to Cushing, Oklahoma. The 36-inch pipeline is under construction and will connect to storage and distribution facilities at Cushing.

TransCanada received approval in March 2010 to expand the Keystone crude-oil pipeline system. When completed, the expansion will increase capacity from 590,000 barrels daily to about 1.1 million per day. The system is 83% subscribed with long-term, binding contracts that include commitments of 910,000 barrels per day for an average term of 18 years. The first phase of the Keystone Pipeline has been completed and commercial deliveries of crude oil to U.S. Midwest markets at Wood River and Patoka, Illinois, began on June 30, 2010.

The Keystone XL project would link up with a portion of the Keystone Pipeline that has been built through Kansas to Cushing, Oklahoma. The pipeline will continue through Oklahoma to a delivery point near existing terminals in Nederland, Texas, to serve the Port Arthur marketplace.

While the Keystone XL expansion would provide a stable supply of crude oil to U.S. oil refineries, concerns over the environmental impact of a possible incident (an indirect result of BP Plc’s oil spill in the Gulf of Mexico and Enbridge’s California leak) have generated major regulatory setbacks in recent months.

In the northern U.S., El Paso Midstream Group Inc., a subsidiary of El Paso Corp. and Spectra Energy Corp., is planning a 994-mile Marcellus Ethane Pipeline System (MEPS) to move some 60,000 barrels daily from the Marcellus shale play to destination interconnect points with third-party ethane pipelines and storage facilities near Baton Rouge, Louisiana. MEPS will include a combination of new pipeline and existing rights-of-way and infrastructure, including Spectra’s Texas Eastern system in Pennsylvania and Ohio and El Paso’s Tennessee Gas Pipeline system running from Ohio to the Gulf Coast, converted to ethane service. The estimated in-service date is April 1, 2013. The project is just one of several intended to move ethane from the rich-gas areas of the play to economical markets, as no large ethane market currently exists in the Northeast. Other midstream operators are considering moving ethane to Sarnia, Ontario.

Also in the Marcellus, NiSource Gas Transmission & Storage and UGI Energy Services Inc. are partnering to develop a new gas pipeline to move some 500 million cubic feet per day of increased gas production along NiSource’s Columbia Gas Transmission system in Clearfield, Centre and Clinton counties to interconnections with four other pipelines in north-central Pennsylvania and southern New York. The project has a fourth-quarter 2010 in-service target date.

In other shale plays, Oneok Partners LP plans to invest up to $470 million between now and the end of 2011 in infrastructure projects in the Williston Basin’s Bakken shale in North Dakota and in the Woodford shale in Oklahoma. Spending plans include some $200 million for new well connections, expansions and upgrades to its existing gathering systems, and new compression.

In the Haynesville shale, Enbridge Energy Partners plans to expand its East Texas gas-gathering system by constructing three lateral pipelines into producing areas and a large-diameter lateral from Shelby County to Carthage, Texas. The expansion will increase the company’s take-away capacity from Shelby, Nacogdoches and San Augustine counties to 900 million cubic feet daily. To date, the company has secured 400 million cubic feet per day in commitments. The $142-million project includes 50 miles of 16- to 24-inch-diameter pipelines in the three counties mentioned above, and a 38-mile, 24-inch lateral from Shelby to Carthage. Also planned are a treating facility and additional compression. The projects are expected to be completed in early 2012.

In the Eagle Ford shale, Kinder Morgan Energy Partners has formed a joint venture with Copano Energy to construct a $137-million, 85-mile, 24- and 30-inch pipeline by summer 2011. The system will move SM Energy’s gas from La Salle, Dimmit and Webb counties in Texas to the Freer compressor station in Duval County, and from there to Kinder Morgan’s Laredo-to-Katy pipeline for final delivery into Copano’s Houston Central gas-processing plant.

And, as always, TransCanada-ExxonMobil and BP-ConocoPhillips continue to struggle over which partnership will build an Alaska Gas Pipeline. The TransCanada joint venture plans a $10-billion (or so) 52-inch, 2,140-mile pipeline system from Prudhoe Bay, Alaska, to Red Deer, Alberta, where it will connect with two branches, one going east to Chicago and one going west to San Francisco. Construction of the pipeline, which would move some 4.5 billion cubic feet per day, is expected to launch in 2012 and be completed in 2018.

The BP joint venture would build a 48-inch, 2,000-mile system transporting 4 billion cubic feet daily. It would begin in Alaska’s North Slope with a gas-treatment plant and terminate in Alberta, Canada; or, it could add another 1,500 miles to Chicago.

In May 2010, Alaska Governor Sean Parnell signed legislation for initial planning and development. The bill, HB 369, establishes an in-state gas line project coordinator and development team, charged with defining a workable plan, including routing, permitting and financing, to be presented to the Alaskan Legislature in July 2011.

Globally, about $193 billion will be spent on onshore pipeline projects through 2015. According to Douglas-Westwood’s third edition of The World Onshore Pipelines Report, published in November 2010, about 74% of expenditures will take place in North America, Asia, Eastern Europe and the former Soviet Union. About 68% of the total will be spent on gas pipelines.

Machines make quick work of pipe-laying efforts.

Processing

Along with pipeline-capacity increases, gas-processing facilities are showing a trend toward new or expanded capacity in the U.S., much of it near shale-gas plays.

This year, Dominion Transmission sealed a deal with PPG Industries on an option to purchase land at PPG’s Natrium, West Virginia, commodity-chemicals plant for construction of a gas-processing and fractionation facility. The company plans to separate NGLs at the 56-acre site as part of its previously announced Marcellus 404 Project. The facility will be designed to phase in service for processing of up to 300 million cubic feet daily of rich-gas and fractionation capacity for up to 38,000 barrels per day of NGLs.

The site in Marshall County, West Virginia, is close to Dominion’s TL-404 pipeline, an existing transmission line in Ohio and West Virginia that Dominion plans to convert into a wet-gas service line. It is also close to railroad, pipeline and barging services for marketing NGLs.

Also in West Virginia, Magnum Hunter Resources Corp. plans construction of a new 200-million-cubic-feet-per-day processing plant. The cryogenic plant, which will treat and process gas liquids transported on the company’s Eureka Hunter Pipeline System line in northwestern West Virginia, is expected to be online by October 2011. Gas will come from the company’s 50,000 net acres in West Virginia and Ohio, where the gas trends in the range of 1,200- to 1,400 Btu.

In western North Dakota, Bear Paw Energy plans to build a processing plant near Watford City. The facility will cost about $175 million to build and will process about 100 million cubic feet daily. Gas production in western North Dakota is on the rise, following increased oil production.

In Pennsylvania, Rex Energy LLC plans a new gas-processing plant in Butler County. The facility will be capable of processing 20- to 25 million cubic feet per day at start-up and 40 million per day by first-quarter 2011. In anticipation of continued activity in Butler County, Rex Energy has begun planning a second plant in the area.

In Canada, Spectra Energy Transmission plans a new 200-million-cubic-feet-per-day gas-processing plant west of Dawson Creek in the Montney play of northeast British Columbia. The Dawson plant will be built in two phases, with the first 100 million of daily processing capacity available in late 2011. The remaining capacity will be available in early 2013.

In Colorado, Enterprise Products Partners began operations at its newly completed Meeker II gas-processing plant in the Piceance Basin. The Meeker II expansion doubles the capacity to 1.5 billion cubic feet per day and it can extract up to 70,000 barrels per day of gas liquids. As part of the project, Enterprise constructed a new 13-mile,

w4-inch-diameter NGL pipeline to link the plant to the TEPPCO Chaparral pipeline, which moves NGLs to the fractionation complex at Mont Belvieu, Texas. Enterprise has also begun operations at its recently expanded Shilling and Thompsonville processing plants in South Texas.

In Texas, Eagle Rock Energy has commenced commercial operation of the Phoenix gas-processing plant in the Panhandle. The company has also completed acquisition of gas-gathering and related facilities in Wheeler and Hemphill counties in Texas for some $27 million. The assets include more than 200 miles of gathering pipeline, compression and dehydration facilities.

In the Rockies, Williams Partners LP began operating its fourth cryogenic processing train at the Echo Springs processing plant in Carbon County, Wyoming. The plant adds some 350 million cubic feet per day of capacity and 30,000 barrels daily of NGLs production, roughly doubling Echo Springs’ capacity in both cases.

In Canada, Duke Energy Transmission received National Energy Board authorization to operate the recently redesigned facilities at its Fort Nelson gas-processing plant in northeast British Columbia. The redesign work results in 88 million cubic feet per day of additional capacity, boosting the total by 11% to 878 million per day. The project included changing the treating solution in two of the existing six processing trains.

Storage

Since the beginning of 2005, U.S. gas-storage capacity has grown from about 8.237 trillion cubic feet to nearly 8.691 by October 2010, according to recent data from the EIA. In fact, some 163 billion cubic feet of gas storage was added in 2010, with about 60% going into salt caverns and the rest into depleted reservoirs.

This year, construction plans include a new facility in Colusa County in northern California to be built by Central Valley Gas Storage LLC, a subsidiary of Nicor Inc. The Central Valley gas-storage project is a high-deliverability depleted reservoir with multi-turn services. It will interconnect with PG&E’s gas-transmission system. Central Valley’s facilities include an 11-billion-cubic-feet working-gas reservoir, nine directional drilled injection and withdrawal wells and a gas-handling facility with 10,650 horsepower of compression and dehydration facilities, and a 14.7-mile, 24-inch lateral between the gas-handling facilities and PG&E’s transmission system. Construction is expected to be completed in fourth-quarter 2011, with firm storage services starting April 1, 2012.

In Alaska, a joint venture between Semco Energy and MidAmerican Energy Holdings Co. will begin construction of a $180-million gas-storage facility on the Kenai Peninsula. Semco subsidiary Enstar Natural Gas Co., the gas utility serving south-central Alaska, and two regional electric utilities, Chugach Electric Association and Anchorage’s city-owned Municipal Light and Power, have contracted for the initial capacity of 11 billion cubic feet. The joint venture will consider an expansion to 16 billion. Semco owns 70% of the project and MidAmerican owns 30%. MidAmerican stepped into the project when TransCanada Corp., which had been pursuing the project with Semco, decided to withdraw.

Near the Henry Hub in Louisiana, AGL Resources’ subsidiary, Jefferson Island Storage & Hub LLC, plans to expand its gas-storage facility. The two additional caverns will increase working-gas capacity from 8 billion to about 20.

Also, new oil storage is on the way at the Cushing Hub in Oklahoma. Magellan Midstream Partners LP plans to construct an incremental 2.25 million barrels of crude storage in conjunction with a private investor group. Combined with an initial 2 million barrels announced in May 2010, the project now totals 4.25 million barrels of storage supported by long-term customer contracts. Magellan will be the majority owner and operator of the storage, which is expected to be fully operational by the end of 2011. Also, the company completed its acquisition of 7.8 million barrels of crude storage and more than 100 miles of active petroleum pipelines from BP Pipelines Inc. for $289 million.

Elsewhere, Sempra Pipelines & Storage, a unit of Sempra Energy, announced that its Mississippi Hub gas-storage facility is now operational. Sited at the Bond Salt Dome in Simpson County, Mississippi, the Mississippi Hub has access to the shale-gas plays in East Texas and Louisiana, traditional gas supplies in the Gulf of Mexico and along the U.S. Gulf Coast, and liquefied natural gas imports. A second cavern, which will add 7.5 billion cubic feet of working-gas storage capacity, is under construction and is slated for completion in second-quarter 2012.

Recommended Reading

TGS, SLB to Conduct Engagement Phase 5 in GoM

2024-02-05 - TGS and SLB’s seventh program within the joint venture involves the acquisition of 157 Outer Continental Shelf blocks.

StimStixx, Hunting Titan Partner on Well Perforation, Acidizing

2024-02-07 - The strategic partnership between StimStixx Technologies and Hunting Titan will increase well treatments and reduce costs, the companies said.

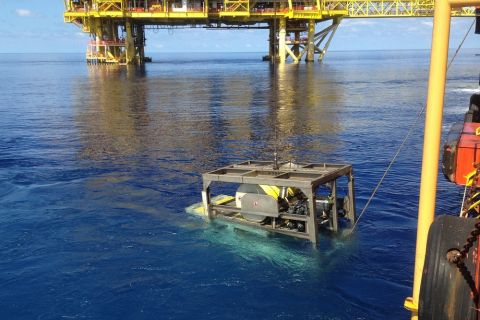

Forum Energy Signs MOU to Develop Electric ROV Thrusters

2024-03-13 - The electric thrusters for ROV systems will undergo extensive tests by Forum Energy Technologies and SAFEEN Survey & Subsea Services.

Axis Energy Deploys Fully Electric Well Service Rig

2024-03-13 - Axis Energy Services’ EPIC RIG has the ability to run on grid power for reduced emissions and increased fuel flexibility.

TotalEnergies Rolling Out Copilot for Microsoft 365

2024-02-27 - TotalEnergies’ rollout is part of the company’s digital transformation and is intended to help employees solve problems more efficiently.