Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

DNV, the independent energy expert and assurance provider, is looking for partners to join a new joint industry project (JIP) to accelerate the development of floating offshore wind substations. The objective is to align industry best-practice and update available substation standards making requirements and guidance more applicable to the infrastructure for floating wind. Kristin Nergaard Berg, senior principal consultant, offshore wind project engineering and due diligence with DNV, explains:

- The substation is a very important structure for a conventional offshore wind farm and is critical for power transmission. Why do you think the level of industry attention on the development of substations for floating offshore wind hasn’t been as high?

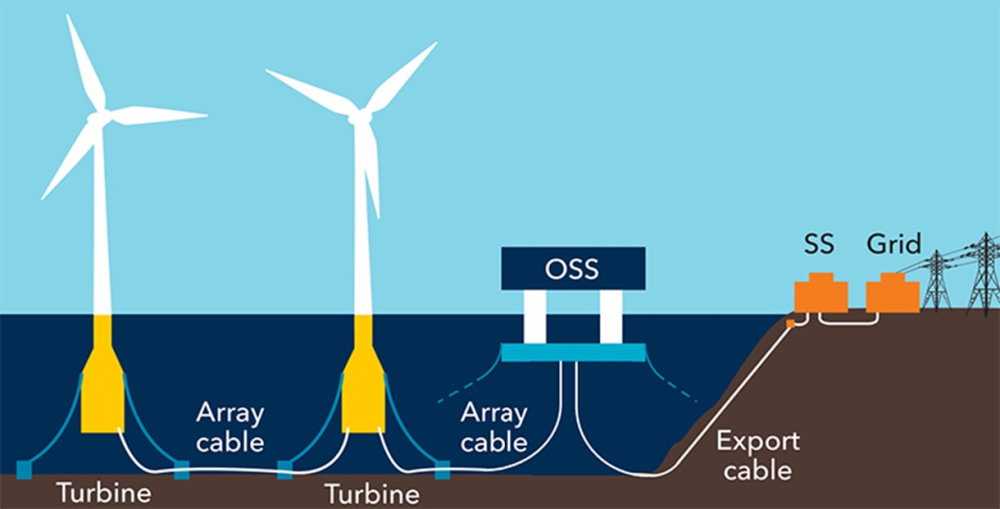

So far, the focus of offshore wind has mainly been on developing bottom-fixed wind farms, maturing the technologies required and ensuring projects are economically viable. In recent years, the industry’s attention has turned towards floating wind to access new and more attractive wind resources. Initially, the focus for floating wind has been on the floater, mooring, integration with existing turbines generally made for bottom-fixed structures. Further, qualifying these technologies, piloting integrated systems, and managing risks. Substations come as a next step when considering scaling-up from single or few turbines to wind farms. From the response received so far from the industry, floating substations is now definitely on the agenda of many players.

- There is currently no standard available for floating offshore wind substations, just bottom-fixed: DNV-ST-0145. What similarities will the updated standard have to this and what differences will be addressed?

While there are some similarities related to the basic function of a substation, for example, safety principles, the marine environment and so on, the floating case sets special requirements to ensure that the power equipment is suited and qualified for the floater movements. Further, also requirements for the floating structure needs to be formulated based on the current requirements for floating wind turbines structures (DNV-ST-0119) and oil and gas floating structures.

- What were the key findings from the call for comments to the JIP? How will this insight be used for developing concepts for floating substations?

The standard DNV-ST-0145 does not cover power cables, and generally there are limited requirements and guidance for dynamic power cables today, although DNV-ST-0119 addresses this to a certain extent. From our discussions with the industry, this is a subject that the JIP needs to study. Power cables are critical for power transmission, both from the floating turbines to the substation and for export to shore. The floating case requires cables of a dynamic design which introduces increased risk for fatigue, and larger wind farms will generally need export cables of higher operation voltage than those that have been qualified for dynamic cables to date.

DNV will address this in the JIP, and plans to agree with the JIP participants in which standard the findings related to cables will be implemented.

- Please provide some real-life examples of risks (commercial, technical, health, safety and environmental) that are being targeted in this JIP?

Commercially, some examples include specifications and standards that can be used for purchasing and contracting and transparency on technology maturity. On the technical side, requirements for power equipment availability and reduced risk for outage, loss of power production from wind farm, excessive energy system loss or low efficiency, cable fatigue and requirements for qualification.

- The objective of the JIP is to align industry best-practice allowing for an accelerated technology development and to close gaps in available substation standards. Can you explain this further?

There is currently no standard that addresses how to design and qualify a floating substation. Though there is an awareness that floating substations brings new risks, there is not an industry-aligned understanding of the detail of these risks, how to mitigate them and the efforts involved. There also exists different opinions on how mature the different technology components are for this application. In this project, DNV is aiming to bring together developers, infrastructure operators, technology developers and suppliers to map out state-of-the-art solutions. In other words, where is industry with the required technologies today? What technology gaps are still there and how shall these be qualified? What existing standards can we learn from and what do they lack for this new use-case?

- DNV’s latest ETO predicts that the installed floating wind capacity will grow to over 260 GW and that the technology will reach commercial-scale deployment in the next 15 years. How dependent is that projection on the acceleration of floating substations?

This projection is dependent on the acceleration of substations to convert the power for transmission to consumers as floating wind farms typically will be at some distance from shore. For some floating wind areas, you may have the option of using bottom-fixed substations, say, down to 100 m. There are also initiatives looking at subsea substations, where the whole substation is placed on the seafloor. However, DNV experiences that for most of these 260 GW wind farms, floating substations will be the solution the industry is looking for. DNV, therefore, thinks it is fair to say that the industry needs floating substations to achieve the predicted scale-up of floating wind and contribute to a sustainable energy transition.

- Overall, what tangible value can be derived from working together in a JIP format for the development of new technologies to advance the energy transition?

Speed is essential to the energy transition. DNV experiences that clearer requirements increase speed and quality, enable implementation of new technology and frees capacity for more innovation. In DNV’s JIP model, several companies work together and are part of defining new requirements. In this way, the results benefit from the most up-to-date experience on the industry’s status and challenges, and the working model also speeds up the implementation of new requirements in the industry. From other DNV-led JIPs, the firm also receives a lot of feedback on the networking effects of different parties working together, increasing the understanding of the challenges in the different steps of a value chain, which in turn benefits value creation in the longer run.

Kristin Nergaard Berg is a senior principal consultant, offshore wind project engineering and due diligence in energy systems at DNV, supporting customers within offshore wind; floating and bottom fixed. She has worked in the energy business since 2001 and in DNV since 2008. In many of her assignments she works as the interface between technology, people and project management, covering such areas as JIP’s, technology qualification and advisory. She has an MSC in Physics from 2001.

Kristin Nergaard Berg is a senior principal consultant, offshore wind project engineering and due diligence in energy systems at DNV, supporting customers within offshore wind; floating and bottom fixed. She has worked in the energy business since 2001 and in DNV since 2008. In many of her assignments she works as the interface between technology, people and project management, covering such areas as JIP’s, technology qualification and advisory. She has an MSC in Physics from 2001.

Recommended Reading

CEO: Coterra ‘Deeply Curious’ on M&A Amid E&P Consolidation Wave

2024-02-26 - Coterra Energy has yet to get in on the large-scale M&A wave sweeping across the Lower 48—but CEO Tom Jorden said Coterra is keeping an eye on acquisition opportunities.

E&P Earnings Season Proves Up Stronger Efficiencies, Profits

2024-04-04 - The 2024 outlook for E&Ps largely surprises to the upside with conservative budgets and steady volumes.

Oil and Gas Chain Reaction: E&P M&A Begets OFS Consolidation

2024-04-26 - Record-breaking E&P consolidation is rippling into oilfield services, with much more M&A on the way.

Uinta Basin: 50% More Oil for Twice the Proppant

2024-03-06 - The higher-intensity completions are costing an average of 35% fewer dollars spent per barrel of oil equivalent of output, Crescent Energy told investors and analysts on March 5.

73-year Wildcatter Herbert Hunt, 95, Passes Away

2024-04-12 - Industry leader Herbert Hunt was instrumental in dual-lateral development, opening the North Sea to oil and gas development and discovering Libya’s Sarir Field.