Presented by:

Editor's note: This "Tech Trends" section appears in the new E&P newsletter. This weekly section highlights the latest upstream technologies and services for the oil and gas industry. The copy herein is compiled from press releases and product announcements from service companies and does not reflect the opinions of Hart Energy. Submit your company’s updates related to new technology products and services to Ariana Hurtado at ahurtado@hartenergy.com.

Subscribe to the E&P newsletter here.

Service delivers real-time insights to optimize reservoir exposure and enhance well economics

Schlumberger has released the PeriScope Edge multilayer mapping-while-drilling service. The service expands the depth detection range and improves resolution compared to existing services while using cloud and digital solutions to offer reservoir insights. This reduces uncertainty and ensures optimal reservoir exposure while drilling, enhancing well construction efficiency. Measurements expand the depth of detection and improve the resolution compared with previous bed-boundary detection services, enabling the service to deliver clearer boundary delineation, even for multiple layers of 3 ft or less. The multilayer service uses deep-resistivity technology and a traverse antenna for multidirectional measurements to reveal up to eight bed-boundary layers, providing definition and certainty beyond a 25-ft radius. Leveraging these capabilities, the PeriScope Edge service helps drillers sustain a more accurate trajectory while inside the reservoir, which contributes to greater reservoir exposure that leads to optimal production.

Bringing benefits of cloud geoscience technologies to E&P in China

CGG GeoSoftware and Amazon Web Services (AWS) extend their collaboration in the global E&P industry to China. GeoSoftware 11.0, CGG’s portfolio of reservoir characterization and petrophysical interpretation software solutions, is now available in the AWS China region for the Chinese E&P industry. To resolve common reservoir modeling challenges in China, owing the complex geology, thin layers and strong heterogeneity within reservoirs, greater accuracy is needed in estimating uncertainty to reduce risk. Jason RockMod geostatistical seismic inversion within the product is designed specifically to address these challenges by providing highly detailed reservoir characterization to produce more accurate reservoir models. By combining Jason inversion technology with the ability to scale and access vast computing resources, it is possible to explore more modeling scenarios with greater complexity and simultaneously generate dozens to hundreds of realizations from geostatistical seismic inversion. AWS offers elastic and scalable cloud infrastructure to run these applications, enabling geoscientists, engineers and researchers to innovate beyond the limitations of on-premises infrastructure.

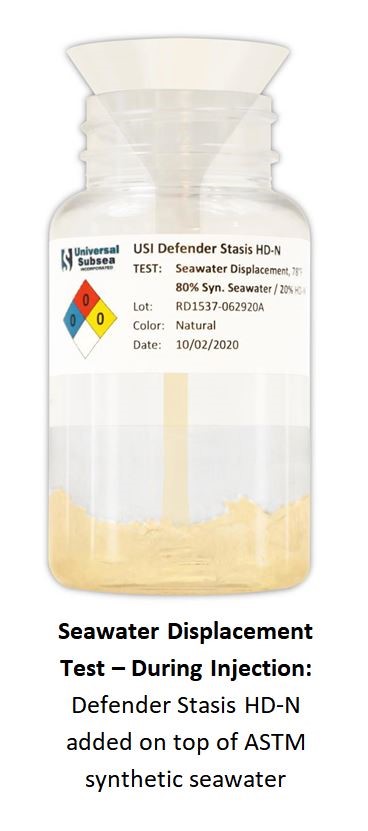

High-density equipment preservation and hydrate prevention fluid deployed to four Gulf of Mexico subsea wells

Universal Subsea Inc. has developed and deployed the industry’s first high-density subsea equipment preservation and hydrate prevention fluid. This environmentally friendly fluid has been injected into the access bore of four subsea wells in the Gulf of Mexico to date. Defender Stasis HD was formulated to protect subsea tree mandrels, tree access bores, tubing head spools and similar subsea equipment. The fluid has properties that protect subsea equipment from corrosion, calcareous deposits and marine fouling, while preventing costly methane hydrate formations in the access bore of trees where gas may accumulate. It is nontoxic, biodegradable, non-bioaccumulating, non-sheen forming and non-hydrate forming. This high-density synthetic oil is classified as a subsea equipment preservation fluid in compliance with U.S. EPA NPDES GMG290000 and is approved for direct release from sea to subsea oil and gas facilities. The product meets the strictest regulatory requirements for offshore oil-producing nations worldwide.

Improving supply chain efficiencies with blockchain smart contracts

A partnership between Kongsberg Digital and Data Gumbo enables Kognitwin

customers to take advantage of the combined power of digital twins with Data Gumbo’s interconnected industrial smart contract network, GumboNet, powered and secured by blockchain. The combined technology offerings improve supply chain efficiencies and transactional accuracy and transparency to drive value for heavy asset industries. Kognitwin changes the nature of working with industrial data, allowing data streams to change enterprise workflows. When deployed with automated smart contracts on GumboNet, customers, vendors and suppliers can integrate specific transactional data, resulting in comprehensive real-time and predictive digital replicas of industrial heavy assets. It will integrate with GumboNet to codify the triggering of supply chain transactions on smart contracts and automated payments. End users will experience real-time updates to contractual transactions based on current data sets, viewable in the digital twin context. The partnership addressed global operators’ need to improve supply chain management by empowering operators to reduce processing times, access real-time data to increase confidence in processing and aid strategic business decision-making throughout their supply chains.

A comprehensive 3D visualization of critical assets in oil and gas

Eye-bot Aerial Solutions and VEERUM have partnered to deliver access to the most comprehensive advanced 3D datasets in the oil and gas construction and infrastructure sectors. Combining Eye-bot’s 3D datasets, derived from drone- and ground-based data collection and data processing, with VEERUM’s asset management and visualization software equates to unparalleled value for asset and capital project managers as well as myriad other stakeholders. The collaboration between the companies enables an asset owner to remotely access, collaborate and analyze asset data in the context of 2D and 3D modeling. The collaboration can reduce operational site exposure hours by 50%, reduce inspection costs up to 25% and improve construction progress reporting by more than 30% in accuracy and availability.

Longest stroke and heaviest lift rod pumping surface unit

Logan Industries International Corp. has partnered with inventor Dave Krug to manufacture the 480 PLUS rod pumping surface unit in Texas. Initially, the product was focused on electric submersible pump conversion wells, where increased polished rod travel along with heavier lift ratings provide improved fluid production and fewer rod reversals. Simplified mechanical arrangements are combined with true downhole pump process control. The operation is derived from the real work produced downhole (previous pump strokes ability to fill with fluid plus the rod’s capability to fall), not a preset motion profile. Both process variables, monitored in real time, regulate rod string direction, dwell, speed, force limiting and total strokes per minute. All this is accomplished without the use of a variable speed electric motor drive, meaning no nuisance faults during brown outs. Additionally, 480 PLUS has no minimum speed due to cooling and lubrication requirements.

Recommended Reading

U.S. Shale-catters to IPO Australian Shale Explorer on NYSE

2024-05-04 - Tamboran Resources Corp. is majority owned by Permian wildcatter Bryan Sheffield and chaired by Haynesville and Eagle Ford discovery co-leader Dick Stoneburner.

Scott Sheffield Among Investors in Australian Shale Gas IPO

2024-06-27 - The operator who sold Pioneer Natural Resources Co. to Exxon Mobil in May for $59.5 billion joins his son Bryan Sheffield in shale gas investment Down Under.

US Shale Leaders Set Pricing for Tamboran Resources’ IPO

2024-06-17 - Tamboran Resources’ appraisal wells indicate the Beetaloo Basin target formation is similar to the Marcellus Shale in its geophysical properties.

Aussie Shale’s Tamboran Resources Prices IPO in Range but for Fewer Shares

2024-06-27 - Among those buying the Australian shale-gas developer’s pre-trade shares were U.S. wildcatter Bryan Sheffield and completions pressure-pumper Liberty Energy.

Berkshire Hathaway Boosts stake in Occidental Petroleum to Nearly 29%

2024-06-19 - Warren Buffett's Berkshire Hathaway Inc. acquired another 2.95 million shares in Occidental Petroleum.