Sponsored by:

Editor's note: This "Tech Trends" section appears in the new E&P newsletter. This weekly section highlights the latest upstream technologies and services for the oil and gas industry. The copy herein is compiled from press releases and product announcements from service companies and does not reflect the opinions of Hart Energy. Submit your company’s updates related to new technology products and services to Ariana Hurtado at ahurtado@hartenergy.com. Subscribe to the E&P newsletter here.

Valves reduce nonproductive time and risk of catastrophic well loss

SPM Oil & Gas has released its KOP AM20 Series Gate Valves, which are designed to reduce nonproductive time and the risk of catastrophic well loss while lowering inventor costs. The valves allow shut in flow for every operation of the wellhead, tree system and choke-and-kill manifolds, from drilling and completion to pumping and production. The valve offers safety by ensuring a gas-tight seal from pressures as high as 10,000 psi and advanced coating guards against high wear, corrosion resistance and low-friction factors for low-operating torque. The series features a simplified design that is not only smaller and lighter for greater cost savings but also provides part interchangeability to simplify inventory requirements. It withstands harsh conditions for more than 600 endurance cycles, representing a 60-year lifespan without grease injection. The KOP AM20 Gate Valves increase the maintenance period by 50% compared to other gate valves in the market.

Technology reduces decision-making time and costly mistakes in the field

Ikon Science has released user-centric enrichments within Curate. Curate is a scalable, cloud-enabled, subsurface knowledge management product that enables energy companies to best leverage and contextualize disparate existing data, regardless of the source, for data democratization and business learnings that drive faster and more accurate decision-making. It helps companies accelerate exploration, minimize portfolio risk and optimize production activities, achieving greater results while preserving capital and human resources for a stronger bottom line. The additions include a collaborative workspace, well viewer, seismic viewer, attribute analyzer and mapping and contouring features. Linking these user-centric enhancements with tailored workflows into the single cloud-enabled workspace, the technology provides immediate open access to enterprise data and best-in-class workflows from anywhere for real-time dynamic collaboration within and across projects. This empowers energy companies to minimize missteps in the field and greater realize greater efficiencies for a stronger bottom line.

Seismic data tool focuses on user experience

Ikon Science also has released the RokDoc version 2021.4. Functionality enhancements include an updated version of the Rose Diagrams plots in the Pressure and Stress Module. The technology can extract more value from multicomponent seismic data by using PP-PS mode in the joint impedance and facies inversion, and it better controls default colors in plots, new-window behavior and 2D session management. It also includes an updated saturation workflow with the option to apply Backus averaging on multiple well logs and an improved external interface that gives users the ability to capture parameters, control units and test code in real time. By bringing digital transformation to knowledge management, Ikon aims to help customers make the best moves by improving accuracy, accelerating results and lowering costs.

Collaboration helps streamline how energy operators acquire, process and action field data

Schlumberger and AVEVA will integrate edge, AI and cloud digital solutions to help operators optimize oil and gas production. The companies will work together to streamline how energy operators acquire, process and action field data for enhanced well-site efficiency and performance. Initial focus of the collaboration includes linking edge systems to applications in the DELFI cognitive E&P environment to better manage equipment health and optimize performance. The collaboration will bring to market the Internet of Things (IoT) and cloud capabilities of both companies. This includes the data management platform capabilities of the AVEVA PI System and Schlumberger domain expertise and analytics capabilities provided by Agora edge AI and IoT solutions and the DELFI environment. The companies also plan to join technology integrations, sales and service support and go-to-market activity.

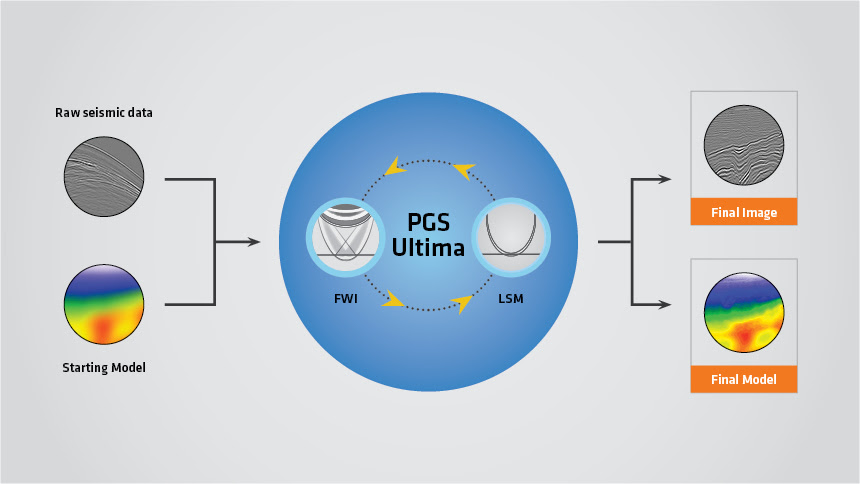

A new imaging tool provides better images faster

PGS Ultima is a move away from traditional sequential processing to a simultaneous inversion combining velocity model building and least-squares imaging. With the tool, accurate models and images can be derived faster, as the simultaneous inversion resolves both using the same raw seismic data. Ultima can bypass most processing in a seismic sequence because it uses raw seismic data as input, and it has the potential to reduce the time taken for an imaging sequence by up to 50%. Full waveform inversion (FWI) is normally run at the beginning of a processing sequence and is the main tool for velocity model building. Least-squares migration (LSM) requires an accurate velocity model, so it happens much later in the flow. The simultaneous nature of PGS Ultima means FWI and LSM are now performed in a single framework. It uses raw seismic data, models the full acoustic wavefield, and outputs accurate velocity models and reliable reflectivity.

Recommended Reading

Continental Resources Makes $1B in M&A Moves—But Where?

2024-02-26 - Continental Resources added acreage in Oklahoma’s Anadarko Basin, but precisely where else it bought and sold is a little more complicated.

APA Closes $4.5B Callon Deal, Deepening Permian Roots

2024-04-01 - About two-thirds of Apache’s daily production will come from the Permian Basin after APA Corp. completed its $4.5 billion takeout of Callon Petroleum.

Analysts: Diamondback-Endeavor Deal Creates New Permian Super Independent

2024-02-12 - The tie-up between Diamondback Energy and Endeavor Energy—two of the Permian’s top oil producers—is expected to create a new “super-independent” E&P with a market value north of $50 billion.

Marketed: EnCore Permian Holdings 17 Asset Packages

2024-03-05 - EnCore Permian Holdings LP has retained EnergyNet for the sale of 17 asset packages available on EnergyNet's platform.

Diamondback Energy to Acquire Permian’s Endeavor for $26B

2024-02-11 - Diamondback Energy will acquire Endeavor Energy in a cash-and-stock agreement that will create a Permian juggernaut with a combined value of more than $52 billion in a merger of near equals.