The Equinor-operated Veslefrikk platform. (Source: Equinor. Photo by Øyvind Hagen.)

When T.D. Williamson Inc. (TDW) and Oceaneering decommissioned a pair of pipelines for Equinor in March 2022, they did it from far afield.

Both companies had been working independently on remote monitoring and control technologies. At Equinor’s urging, Oceaneering and TDW ensured TDW’s SmartPlug pipeline isolation tools and Oceaneering’s Liberty ROV could communicate with each other by interfacing the isolation tools through the Liberty ROV Telemetry System to shore. After pre-project planning and testing, the two companies were able to support the decommissioning from shore of a 10-inch outside diameter (OD) gas pipeline and a 16-inch OD oil pipeline at Equinor’s Veslefrikk Field in the Norwegian North Sea. The work, done in 185 m water depth in March 2022, saved eight days of vessel time and associated emissions through the joint approach.

For the project, TDW and Oceaneering worked together much more closely than usual, Gary Anderson, TDW senior manager for sales, eastern hemisphere said.

“The interface we would normally have with subsea companies such as Oceaneering is normally minimal,” he said.

Separately, both companies had been developing remotely controlled systems for use offshore.

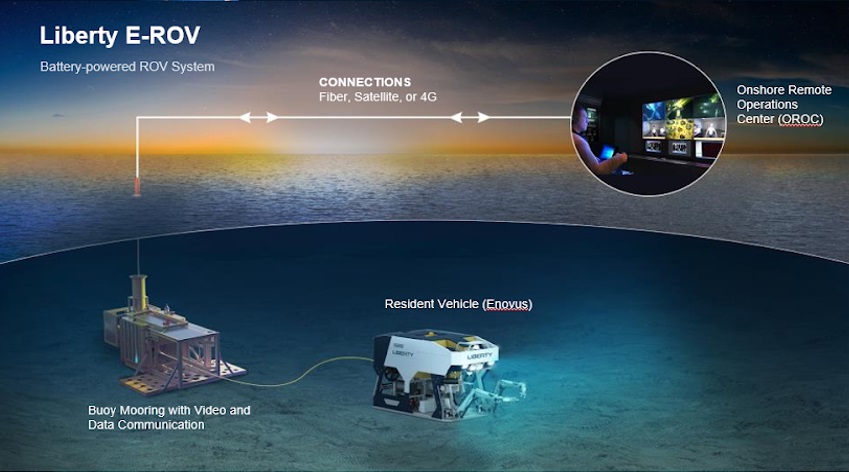

“We had developed a system to remotely communicate with our SmartPlug isolation tool from afar so we didn't need to be on the platform or vessel,” he said. “Oceaneering had developed the Liberty E-ROV system, which they can operate remotely.”

Equinor, aware of both efforts, urged the companies to see if further collaboration could benefit the project, he recalled.

Typically for a subsea pipeline isolation, TDW would mount its equipment on an ROV, and the isolation tool’s operator would communicate with the tool from the vessel that deployed the ROV, Anderson said.

This operation would be different because Oceaneering’s Liberty E-ROV, which can be piloted from an onshore control room, wouldn’t need on-site vessel support.

The companies worked together to ensure TDW’s communication system for the tool would ride alongside the ROV’s communication system.

“There was an immense amount of upfront engineering and upfront planning,” he said.

Kenneth Solbjør, subsea robotics product manager at Oceaneering, called remote piloting the future of ROVs.

“It gets people away from offshore,” he said.

Vessels add mightily to ROV operations budgets and emissions levels, he added. An alternative is a resident subsea robot relying on an integrated buoy system for communication to shore, which means the vessel can be present for deployment and recovery but otherwise is not necessary on site, Solbjør said.

Oceaneering, which has logged more than 14,000 hours of onshore piloting of its Liberty E-ROV system since 2019, has 10 ROV control rooms dotting the globe. The largest of these onshore remote operation centers, in Stavanger, Norway, is where Oceaneering and TDW carried out the Equinor Veslefrikk decommissioning project.

“When you walk into these rooms onshore, you are actually offshore, is the philosophy,” Solbjør said.

The big test of the systems being able to work together, Anderson said, was “when we took our equipment round to the office and hooked it up with the Liberty E-ROV interface and established pretty quickly that this was going to work.”

Even with those concerns addressed, he said, the remote-controlled equipment pairing had not been in the water together, let alone carried out an operation near or on a pipeline.

“At that point, we were going into the unknown,” Anderson said, but at least communications weren’t a concern. Going in, he said, the thinking was that “as long as the communication link was there through the Liberty E-ROV, we should not have a problem in communicating with our tool. And that was exactly the case.”

Isolation tool, isolated

Together, TDW and Oceaneering participated in the decommissioning of the pair of pipelines at Equinor’s Veslefrikk platform in 120 m of water. During the project, TDW’s isolation tool was used in the pipeline to make it possible to depressurize one side of the pipeline, while the other side remained at full operating pressure. Once the isolated pipelines were depressurized, saturation divers were able to cut the pipelines.

The pipelines were capped, and the isolation tool was removed from the oil line. It was not possible, however, to remove the tool from the gas pipeline because it ran into a subsea template, Anderson said, and TDW knew that from the outset.

“We had no ability to get the tool out,” he said. “The tool will remain there until the rest of the pipeline is recovered.”

The 16-inch oil pipeline was connected to an existing pipeline system via a Y piece, so it was possible to recover the isolation tool from the other end of the pipeline, he said.

“One was non-recoverable, one was recoverable, and that really depended on where the isolation was. In this case, the subsea template prevented any recovery, and the subsea Y piece allowed for recovery,” Anderson said.

For its part, the Liberty E-ROV was on location at the pipeline where the plug needed to be set, Arve Iversen, subsea robotics project manager at Oceaneering, said.

“T.D. Williamson developed the smart plug technology. They sat in our control room on the beach with a laptop and sent a signal through our ROV system to their communication transducer, and they activated the plugs that way,” Iversen said.

Deploying the Liberty E-ROV from a vessel that was able to leave during the operation saved eight days of vessel time, he added.

“This saved a lot of dollars and at the same time a lot of CO2 emissions,” he said.

Solbjør said the combination of the two technologies made the pipeline decommissioning possible at “a fraction of the price” of traditional methods while being “much more environmentally friendly.”

Solbjør said uptime on the E-ROV is “way beyond 99%,” and when there were issues with the system in its early days of development and deployment, Oceaneering as designer and manufacturer of the unit, was able to correct them quickly.

The E-ROV has racked up more than 14,000 hours of onshore pilot experience while saving 19,000 tons of CO2 emissions in the four years since the robot’s initial deployment, but uptake of the remote technology hasn’t been speedy.

“It's considered new technology,” Solbjør said.

He said there can be trust issues with new technology and often operators want to “sit on the sidelines” to see how the new equipment works in the field for other operators.

“I think they don’t want to be the first one to use it,” Solbjør said. Once they see it actually works, they may opt to try it. “Change is not easy.”

Anderson said the collaboration “benefited us, it benefited Oceaneering, and it certainly benefited Equinor in the long run, both from a technology perspective and a commercial perspective because of the vessel saving time” as well as the continued gas and oil production during the pipeline isolation phase.

Equinor tapped the TDW-Oceaneering remote ops pair-up to collaborate on additional decommissioning projects in the North Sea at similar water depths. Those projects were successfully carried out over the summer.

And given the aging infrastructure throughout the industry, Anderson sees the potential for more collaborative projects.

“We’ve spent the past 50 years developing an offshore infrastructure,” he said. “The reality is that there’s a lot of these assets that now need to be decommissioned.

Recommended Reading

US Drillers Add Oil, Gas Rigs for Third Time in Four Weeks

2024-02-09 - Despite this week's rig increase, Baker Hughes said the total count was still down 138 rigs, or 18%, below this time last year.

US Drillers Cut Oil, Gas Rigs for the First Time in Three Weeks

2024-03-08 - The oil and gas rig count, an early indicator of future output, fell by seven to 622 in the week to March 8, the lowest since Feb. 16.

US Drillers Cut Oil, Gas Rigs for Second Time in Three Weeks

2024-02-16 - Baker Hughes said U.S. oil rigs fell two to 497 this week, while gas rigs were unchanged at 121.

US Drillers Add Most Oil, Gas Rigs in a Week Since September

2024-03-15 - The oil and gas rig count, an early indicator of future output, rose by seven to 629 in the week to March 15.

US Gas Rig Count Falls to Lowest Since January 2022

2024-03-22 - The combined oil and gas rig count, an early indicator of future output, fell by five to 624 in the week to March 22.