Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

Horizontal wells offer increased reservoir contact and generally deliver much higher levels of productivity than their vertical counterparts, but these performance gains come at a cost. Managing horizontal wells and understanding their interactions with the reservoir are extremely complex challenges for petroleum engineers and asset management teams. New diagnostics technology from TGT, specifically designed to assess flow in horizontal wells, can deliver a much clearer picture of well system behavior.

Operating companies want to maximize hydrocarbon recovery in the safest, cleanest and most economical way possible. To do this, they need reliable information on fluid behavior within the well system, that is, the wellbore and the immediately surrounding reservoir rocks. Having an accurate picture of fluid flow in these areas gives teams greater confidence in the decisions they take to enhance production, maximize recovery and rectify well problems.

Flow analysis in horizontal wells is notoriously challenging. Variations in well angle and the extended reservoir contact as well as the presence of mixed fluids and segregated flow, formation changes, fractures and intricate completions all add to the complexity. Conventional production logging tools designed for flow assessment in vertical wells often struggle to deliver what is required.

Under favorable conditions, production logging technology may be able to map the multiphase flows encountered in a horizontal wellbore, but it cannot quantify the flow of fluids exiting or entering the reservoir behind the completion. This means that teams that rely exclusively on flow profiles from wellbore production logs are not seeing the true flow dynamics across the well system. Basing development, production or remediation plans on an incomplete or incorrect flow diagnosis may lead to flawed decisions, lower productivity and reduced asset performance.

More accurate horizontal flow diagnostics

For many years, petroleum engineers have been looking for ways to overcome the drawbacks of conventional production surveys in horizontal wells. Specifically, they wanted a system that could deliver continuous flow profiles across a variety of completion and reservoir scenarios, including fractured formations. The team at TGT has addressed these needs by creating the Horizontal Flow product, which is a new flow-diagnostics resource powered by Cascade3 technology.

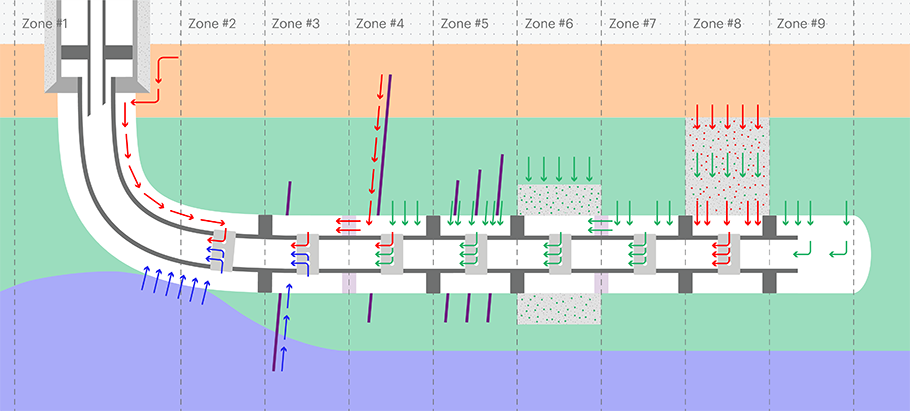

The basis of this new technology is an advanced modeling and simulation engine that predicts the hydrodynamic and thermodynamic behavior of fluids and their surroundings as those fluids flow through the well reservoir system. Purpose-built for horizontal wells, it combines advanced hydrodynamic (fluid motion) and thermodynamic (heat and energy transfer) modeling technologies to translate temperature, pressure and other well system data into continuous reservoir flow profiles.

Crucially, the flow profiles produced reflect flow into and out of the reservoir, thereby delivering a true picture of inflow and outflow in even the most challenging wells, including those with natural or hydraulically induced fractures. This is important because, although fractures can boost the performance of a well or reservoir, they can also provide pathways for water or gas breakthrough. The new technology evaluates all three common types of flow pattern (radial, spherical and linear/fracture) encountered in horizontal well systems. This makes it possible to provide an accurate assessment of the linear flow that is occurring in fractures and to determine fracture contribution. This is particularly useful when combined with the Chorus acoustic sensing system that identifies fracture locations along the wellbore.

Armed with detailed insights into the complex flow regimes in well systems, asset teams can manage well and reservoir performance much more effectively. The new approach enables them to

- Establish reliable flow profiles;

- Locate water or gas breakthroughs;

- Reduce carbon footprint;

- Maintain a more accurate reservoir model;

- Measure effective pay length;

- Make more accurate reserves assessments;

- Reveal crossflows;

- Assess inflow control devices and packers;

- Assess fractures;

- Make more accurate production forecasts; and

- Optimize completion designs.

The new workflow can also be used to estimate or validate other key parameters such as reservoir pressure, permeability and skin factor. This independent verification of key parameters can help reservoir engineers to resolve uncertainties, improve history matching and optimize their dynamic reservoir model.

Horizontal wells represent a significant resource investment. Production engineers, reservoir engineers and the wider asset team need to ensure that each well system performs to expectations by achieving production targets and maximizing recovery. TGT’s new Horizontal Flow diagnostics technology solves key challenges and helps keep well and reservoir performance on track.

Recommended Reading

BP Pursues ‘25-by-‘25’ Target to Amp Up LNG Production

2024-02-15 - BP wants to boost its LNG portfolio to 25 mtpa by 2025 under a plan dubbed “25-by-25,” upping its portfolio by 9% compared to 2023, CEO Murray Auchincloss said during the company’s webcast with analysts.

BP Restructures, Reduces Executive Team to 10

2024-04-18 - BP said the organizational changes will reduce duplication and reporting line complexity.

Kimmeridge Fast Forwards on SilverBow with Takeover Bid

2024-03-13 - Investment firm Kimmeridge Energy Management, which first asked for additional SilverBow Resources board seats, has followed up with a buyout offer. A deal would make a nearly 1 Bcfe/d Eagle Ford pureplay.

M4E Lithium Closes Funding for Brazilian Lithium Exploration

2024-03-15 - M4E’s financing package includes an equity investment, a royalty purchase and an option for a strategic offtake agreement.

Laredo Oil Subsidiary, Erehwon Enter Into Drilling Agreement with Texakoma

2024-03-14 - The agreement with Lustre Oil and Erehwon Oil & Gas would allow Texakoma to participate in the development of 7,375 net acres of mineral rights in Valley County, Montana.