Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

A digital completion technology has delivered more than 36,000 stages without a single wireline or pressure control incident. This incident-free safety and reliability track record encourages oil and gas operators to adopt a digital infrastructure to improve hydraulic fracturing and wireline operations. Intelligent Wellhead Systems Inc. has achieved this with its inVision technology platform.

The digital infrastructure technology integrates software, sensors and engineered safety controls to automate standard operating procedure compliance for operating frac valves and remotely supervising wireline operations. Reduced frac valve activation time has reached 55%, and wireline valve action times have been cut by 59%. Well swap times on some pads have been reduced by half.

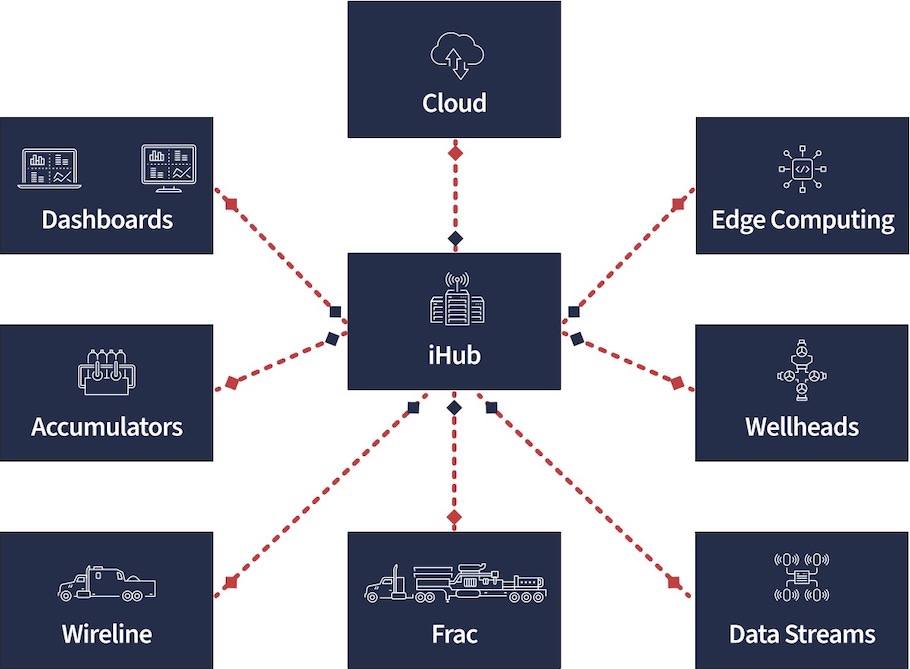

The technology features a robust data acquisition and control system, iHub, the digital completion technology brain at the wellsite for integrating hydraulic fracturing, wireline and pressure control job data to create customized workflows, threshold alerts and other analytical applications. The latest platform innovation is implementing operator-driven analytics on the Edge or in the Cloud. Operators and service companies can implement their completion performance-enhancing algorithms by accessing real-time frac, wireline, pressure control and other third-party data. iHub real-time bidirectional sync capabilities eliminate the gap between Cloud and field implementations, and APIs are available to ensure connectivity and integration with other applications.

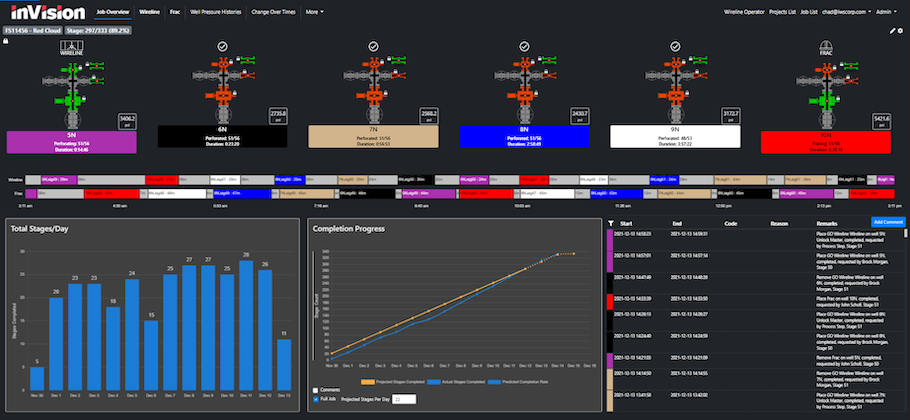

Along with these innovations, inVision software technology includes a remote operations dashboard that visualizes critical completion data to help users reduce risk, lower cost and improve uptime. The real-time, configurable digital display, a virtual window into all onsite operations, is accessible on wellsite tablets and remote desktop computers. Visualizing valve placement and well activity status helps reduce human error and improves decision-making.

The software leverages a variety of inVision sensors and engineered controls that improve completion efficiency:

- Valve position sensors provide digital valve position verification to eliminate manual visual inspection.

- Valve handle position sensors give users a visual representation of the wellhead valve alignment by measuring the position of the control valve handle.

- Pressure sensors on the backside of each well detect when frac pressure exceeds frac threshold pressure to prevent users from unlocking the wrong valves.

- Wireline spools detect the wireline presence in the well and prevent users from unlocking valves that may cut wireline.

- Hydraulic valve lockouts prevent accidental well shut-ins and include a visual valve position indicator and digital and manual emergency bypasses.

If a wellsite user requests access to a well and the inVision software detects wireline in the hole or active frac pressure, the request is disabled. If the system detects it is safe, and the request is approved, a three-way Digital Handshake is initiated and conducted over inVision tablets. Each user enters their unique PIN, and the process is executed and recorded. If an unsafe condition is detected at any time, the inVision system locks out the relevant valves and notifies the user, then unlocks once safe conditions have been restored.

On two-well simul-frac operations, the inVision Digital Handshake process and interlock controls are being used to keep well swaps safe and streamlined. With at least twice as many valves involved in simul-frac operation well swaps, inVision standard operating procedures have been adopted to support complex valve sequencing to reduce human error.

For single well fracs, zipper fracs, and simul-frac operations, inVision digital completion time-series data are delivered with a standard data model that can be analyzed and visualized on the Corva Completions suite that automates engineering analysis and modeling. The inVision SIMOPS app lets engineers develop key operational learnings from digital completion data with Corva’s data analytics and AI technologies. Data and plug-and-perf reports generated by inVision are also easily imported to WellView, Peloton’s integrated well data lifecycle analysis and visualization solution.

The ability to remotely actuate hydraulic valves to reduce wellsite personnel exposure to potential hazards is the latest inVision development. Automating remote operations of valves promises to improve stage efficiency further.

In field test, this development will see its first commercial application at the end of March 2022 with Aethon Energy, an operator in the Haynesville that has leveraged the inVision Technology Platform since 2020.

Recommended Reading

What's Affecting Oil Prices This Week? (May 6, 2024)

2024-05-06 - Stratas Advisors forecast that oil demand for 2024 will increase by 1.41 MMbbl/d in comparison to 2023 and that oil demand will increase by 810,000 bbl/d in comparison to 2Q23.

It’s Complicated: E&Ps Find Some Financial Tailwinds, But It’s Not All Smooth Sailing

2024-05-03 - Relatively stable WTI prices in the $80s/bbl provide some breathing room as companies allocate cash for operations, and pragmatism is seeping into the energy transition movement.

Pitts: US, Qatar Face off in LNG ‘Olympics’

2024-05-03 - In the LNG exporting space, the U.S. is squaring off with its fiercest competitor, Qatar, with both countries expected to outpace Australia

Chesapeake Stockpiles DUCs as Doubts Creep in Over Southwestern Deal

2024-05-02 - Chesapeake Energy is stockpiling DUCs until demand returns through growth from LNG exports, power generation and industrial activity.

Majors Aim to Cycle-proof Oil by Chasing $30 Breakevens

2024-02-14 - Majors are shifting oilfields with favorable break-even points following deeper and more frequent boom cycles in the past decade and also reflects executives' belief that current high prices may not last.