Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

As the emphasis in the oil and gas industry moves toward smarter, more efficient and environmentally conscious ways to explore and develop new fields, digital technology is playing a pivotal role in opening up new horizons.

For the Austrian-based integrated oil, gas and chemicals company, OMV, going digital has been a primary focus. In 2018 the company invested heavily in preparing for a rapidly changing industry landscape, and its E&P arm began to pursue a strategy to become a digital frontrunner in the upstream industry.

One of its main areas of concentration was the automation of workflows for the design, planning and execution of oil and gas wells.

The challenge: standardizing processes and connecting silos

Part of OMV E&P’s ambition for digital transformation has been around improving the planning process for its onshore development wells. Many of these are located in challenging drilling environments, where the simplest of tasks, like compiling data to share and checking its accuracy and currency, can consume up to 60% of workforce time.

Previous plans had been drawn up using traditional software, which isolated working teams in silos and dislocated the planning process. Well planners had to access history data and lessons learned in a range of different formats, including PDFs, spreadsheets and word-processing applications. Relevant information was stored in multiple, disconnected offset-well databases, making data hard to access and the entire process both time-consuming and inefficient.

OMV E&P sought a simplified and optimized well-planning solution that would enable teams to work smarter and faster.

Cloud-based solution

To tackle issues with the well planning process, OMV E&P worked with Schlumberger to deploy its cloud-based DrillPlan coherent well construction planning tool, which is enabled by Schlumberger's DELFI cognitive E&P environment.

The well construction planning tool integrates the results from drilling projects into a single, shared database, allowing teams of all disciplines—from operations to geology, petrophysics to completions—to work across the same platform, with the most up-to-date data and insights at their fingertips.

The solution’s circular workflows allow plans to be reworked and improved as new data become available, enabling future programs to learn from the lessons of all well drilling operations to date.

The results: leaner, quicker and more efficient processes

For OMV E&P, connected digital solutions are breaking down the silos. What would have taken three or four years to do is now taking just a couple of months, enabling the planning of wells at much lower costs and greatly reducing ecological footprints.

Using the well construction planning technology for onshore development wells in Austria, OMV E&P’s well planning teams were able to access and visualize offset well data more easily, without having to research past reports.

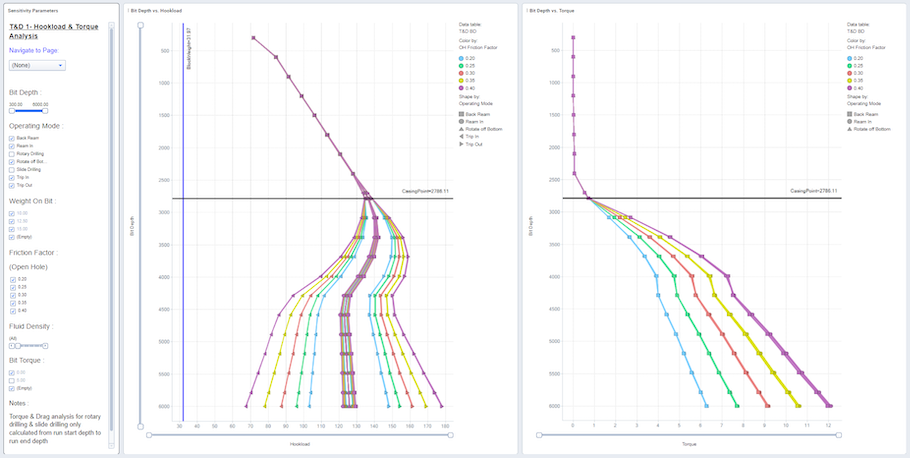

Sensitivity Analysis Visualization—Hookload and Torque Analysis

The automation of repetitive tasks and validation workflows enabled higher-quality drilling programs to be produced more rapidly and more coherently. Engineers were able to identify and analyze risks more quickly, incorporate lessons learned and integrate these into their execution plans to maximize performance.

Cloud adoption led to a raft of statistically significant time savings across the planning phase. The well construction planning tool's powerful data-handling capabilities significantly accelerated the concept selection process, cutting the time taken from two weeks to just two days—resulting in a 600% improvement in efficiency.

Automated reporting capabilities reduced the time required to generate a multiwell drilling program by more than 50%, and the time taken to implement direct learning from offset wells was cut by more than 15%.

Where engineers once needed to enter planning data multiple times into different software interfaces, it became possible to input information a single time to be automatically shared across the well project and applied to different design components. This reduced the time previously spent on reviewing documents and double-checking data by 25%.

With all of these benefits combined, the well construction planning tool helped map out eight wells in the time it would normally take to plan one.

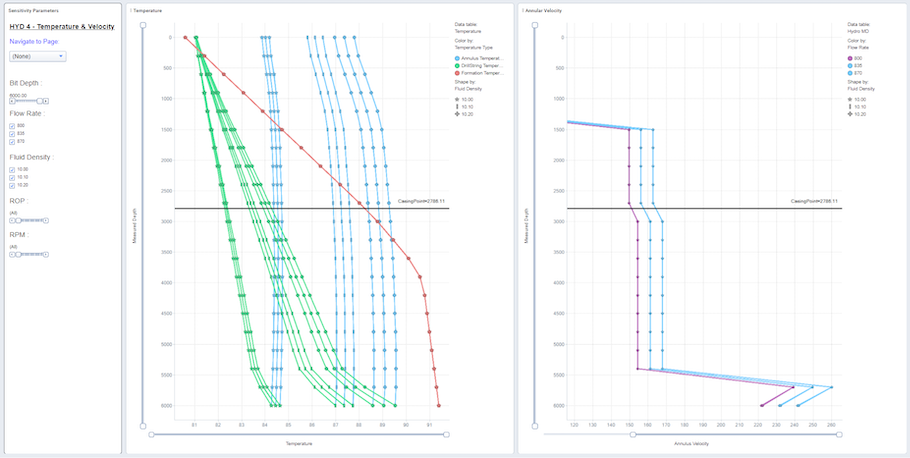

Sensitivity Analysis Visualization—Temperature and Velocity Analysis

A digital road map

The positive outcomes OMV E&P achieved for its Austrian onshore wells have fundamentally changed its perspective on well planning and engineering. The coherent well construction planning technology and the cognitive E&P environment are seen as pivotal in helping achieve digital transformation. This is because they are core in securing the move to automated workflows for delivering efficient and effective projects.

On the back of OMV E&P’s success with its Austrian wells, the well construction planning tool has been rolled out by OMV Petrom to plan onshore wells for its Romanian assets.

Digital transformation is key to the oil and gas industry of the future. With the farsighted adoption of cloud-computing solutions, OMV E&P is now better equipped to reap the rewards the digital revolution can bring to business.

Recommended Reading

Deep Well Services, CNX Launch JV AutoSep Technologies

2024-04-25 - AutoSep Technologies, a joint venture between Deep Well Services and CNX Resources, will provide automated conventional flowback operations to the oil and gas industry.

EQT Sees Clear Path to $5B in Potential Divestments

2024-04-24 - EQT Corp. executives said that an April deal with Equinor has been a catalyst for talks with potential buyers as the company looks to shed debt for its Equitrans Midstream acquisition.

Matador Hoards Dry Powder for Potential M&A, Adds Delaware Acreage

2024-04-24 - Delaware-focused E&P Matador Resources is growing oil production, expanding midstream capacity, keeping debt low and hunting for M&A opportunities.

TotalEnergies, Vanguard Renewables Form RNG JV in US

2024-04-24 - Total Energies and Vanguard Renewable’s equally owned joint venture initially aims to advance 10 RNG projects into construction during the next 12 months.

Sitio Royalties Dives Deeper in D-J with $150MM Acquisition

2024-02-29 - Sitio Royalties is deepening its roots in the D-J Basin with a $150 million acquisition—citing regulatory certainty over future development activity in Colorado.