Stretching hundreds or thousands of feet into the dark waters below a mobile offshore drilling unit (MODU) is the conduit through which all operations and fluids fl ow. The primary purpose of the vessel’s offshore riser system is to enable the safe transportation of fluids and gases from beneath the seafloor and the surface, and vice versa. From the running, operation and retrieval of drillpipe to well control operations and more, any and all processes that require a surface connection to the well are made possible through riser systems.

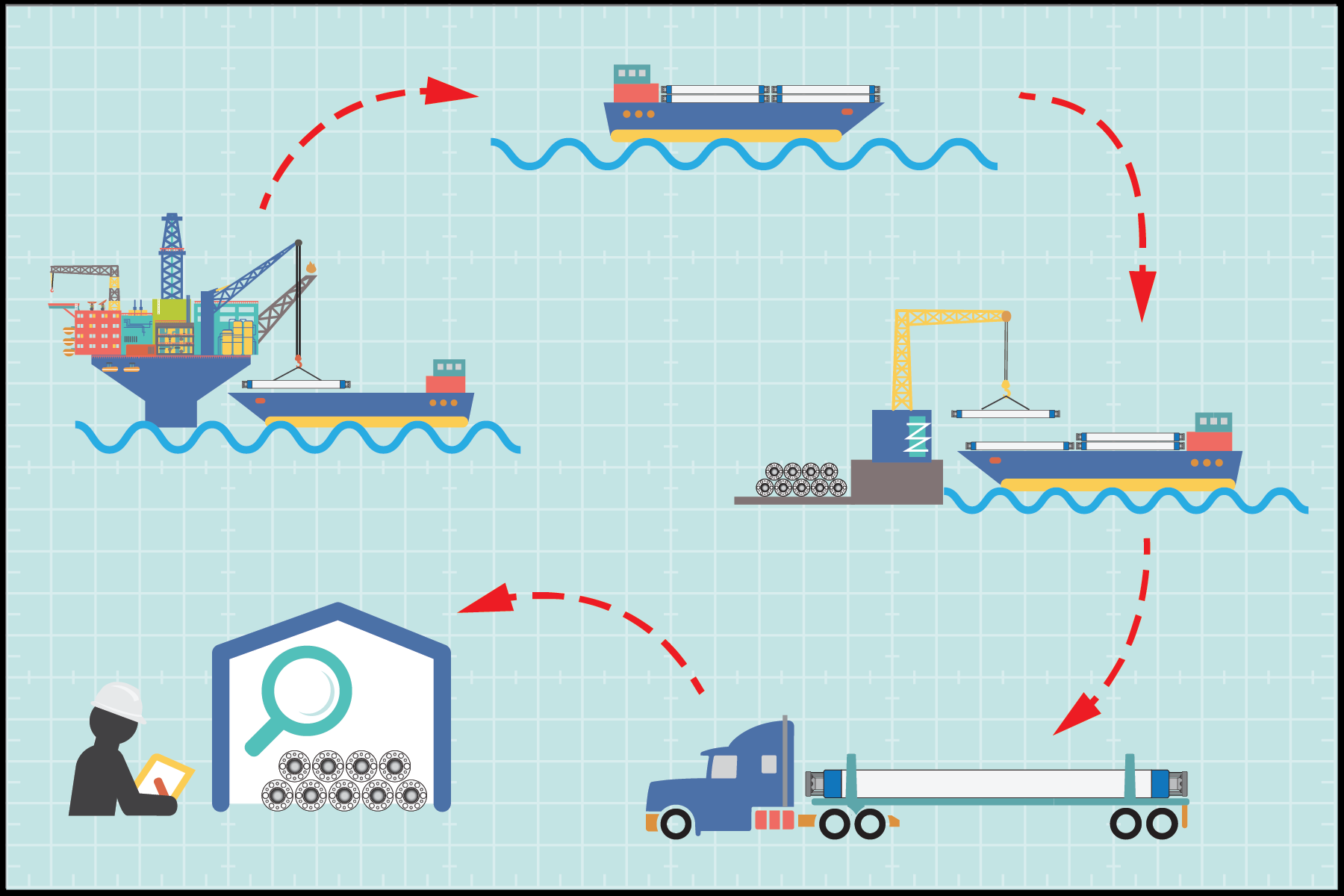

The connection is established through a series of 27-m (90-ft)-long riser joints connected together. The integrity of these individual riser joints is paramount, presently requiring inspections every fi ve years to identify any flaws in need of repair. Logistically complex, the inspection process requires the physical transportation of the joints and other components by water to a landbased facility for disassembly, inspection and repair. This approach requires extensive boat trips and trucking of the riser, according to Stress Engineering Services (SES), a provider of consulting engineering services.

SES sought a way to reduce the complexity and the time and costs associated with the MODU inspection process. By partnering with LaserStream, a specialist in the use of laser-based measurement for the inspection of oil and gas equipment and pipe/tubing, a new approach was developed.

The companies combined the power of conditionbased maintenance and monitoring with laser measurement to determine the condition of drilling riser joints, predict when vital components will require service and determine remaining component life. The program uses synchronized drilling and metocean data, along with measured loads on the riser and wellhead system, data analytics and more.

In addition, the process includes data collected through the use of a laser profilometry bore erosion measurement and inspection system (BEMIS). Featuring a scanner head that rotates 250 rpm, the BEMIS can collect more than 3,000 points of measurement in each rotation. These measurements are collected on the inside diameter (ID) of the main bore and auxiliary line between wells to characterize the state of the drilling riser joints. The datapoints are analyzed using the LaserViewer software to map and determine material loss, characterize features to determine what caused the anomaly and perform detailed dimensional analysis of the entire tube, according to SES.

The BEMIS is deployed through the ID of the riser via a tethered crawler while the riser is on deck and eight joints can be inspected in one day. Field results are available at the site, and a final report identifying damage is available within a week.

Recommended Reading

CEO: Baker Hughes Lands $3.5B in New Contracts in ‘Age of Gas’

2024-07-26 - Baker Hughes revised down its global upstream spending outlook for the year due to “North American softness” with oil activity recovery in second half unlikely to materialize, President and CEO Lorenzo Simonelli said.

Pemex Hits Debt Target, Struggles to Reverse Production Declines

2024-07-26 - Pemex achieved its long-term debt target, which aimed to gets its financial obligations below the $100 billion, while struggling to halt production declines.

Dividends Declared in the Week of July 22

2024-07-25 - Second quarter earnings are underway, and companies are declaring dividends.

NextDecade Appoints Former Exxon Mobil Executive Tarik Skeik as COO

2024-07-25 - Tarik Skeik will take up NextDecade's COO reins roughly two months after the company disclosed it had doubts about remaining a “going concern.”

Freeport LNG Parent Receives Junk-level Credit Score From Fitch

2024-07-25 - Credit-rating firm Fitch Ratings cited the 2 Bcf/d Texas plant’s frequent downtimes among the factors leading to lowering Freeport LNG Investments LLLP’s credit grade on July 25.