Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

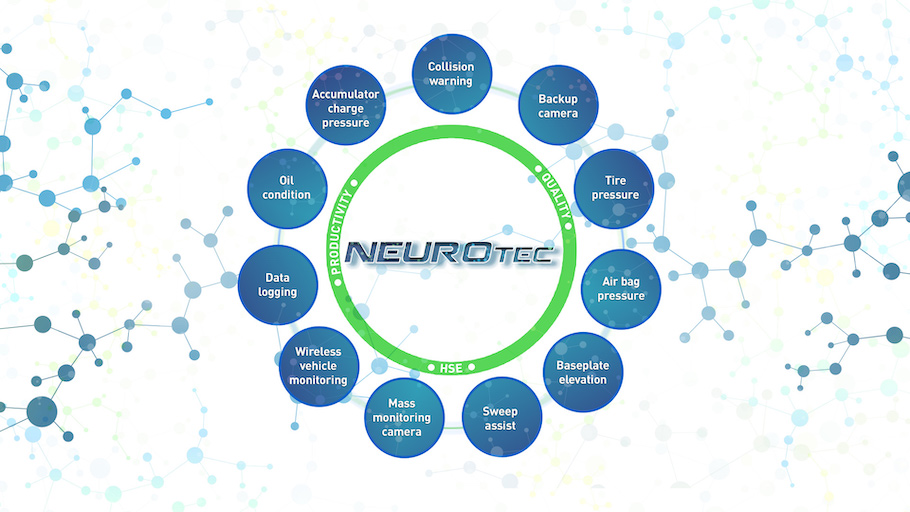

INOVA Geophysical, a land seismic technology company, recently released its NEUROtec technology platform that integrates digital control into critical aspects of the vibroseis vehicle, which enables monitoring systems, automation, safety compliance and maintenance awareness.

"This technology gives instant and remote access to a whole new set of vib functions and has not been done before," the company stated in an email to E&P. "NEUROtec reduces HSE risks and eliminates manual monitoring, while ushering in a new generation of evolved vibroseis that saves a significant amount of time and money."

INOVA Geophysical

In an exclusive interview with E&P, INOVA's Arjun Selvakumar, senior vice president of engineering and technology, provided an in-depth look at this new technology, its applications as well as current R&D in the works.

E&P: What is NEUROtec, and what is the industry need for this technology?

Selvakumar: At INOVA, we are constantly reviewing aspects of the seismic surveying operation to understand how we can improve and optimize. NEUROtec is an example of one such initiative that was launched within the vehicles product line to do just that. It is a collection of smart technologies that enables a new generation of vibroseis that is safer to use, more environmentally friendly, more productive and with exceptional broadband geophysical performance. NEUROtec represents the driving force behind the evolution of vibroseis.

E&P: How is this different from other vibroseis products on the market, and how have other services/tools failed to meet this need?

Selvakumar: Traditional seismic vibrators are large, heavy instruments that require precise control and operation to deliver high-quality vibroseis source energy for subsurface imaging. It requires detailed setup, constant machine-condition and output monitoring, and careful operation. And this needs to be performed thousands of times per day. While improvements have been made over time, much of this has been focused on the quality of the source signal whereas the instrumentation, monitoring and control of the seismic vehicular operations have lagged behind vehicles in other industries such as construction, agriculture, transportation, etc. It has required manual methods that have done little to minimize operator fatigue, improve operational efficiency at a high and consistent level throughout the entire work shift of each operator, or reduce HSE exposure in uncharted, off-road conditions where the job is frequently performed. Previous generations of vehicles have continued to employ manual, labor-intensive methods with little automation of the vibroseis operation whether it be vehicular movement or the vibroseis actuation. Health and monitoring have been done through discrete, non-networked sensors and gauges that require the constant vigilance of the operator.

E&P: How did INOVA Geophysical develop NEUROtec?

Selvakumar: We took our 40-year experience with vibroseis technologies that have spanned numerous successful vehicle generations including the AHV-IV PLS 380 and AHV-IV PLS 364 class as well as the smaller, lighter Univibe UV2 vehicle. In addition, we recently introduced the AHV-V 480 Titan vehicle that provides low-frequency energy in a broadband vibe. Each of these vehicles provided key technologies that have been integrated and further developed into a modern technology framework that is NEUROtec. This new framework is based on a central networked architecture that interconnects all the sensors, systems and controllers on board the vibrator. This network includes parallel processing computers networked together and provides four essential functions: 1) full monitoring of the vehicle, 2) reporting health and status to the operator in a logical and ordered fashion, 3) using the actionable information to automate routine decisions or create condition-based prompts and alerts for operator-based decisions, and 4) automation of certain operations to improve performance and repeatability.

E&P: What are the tool's capabilities and its application?

Selvakumar: The capabilities can be split into these major categories: vibroseis and vehicle operational areas; HSE elements; and status and machine health monitoring and logging. Vibroseis operations are repeatedly performed thousands of times a day by each vehicle as part of a fleet that can number anywhere from 10 to 100. Automating aspects of braking and accelerating to the next source point is of key interest to the operator. Navigation tools within this framework help locate and reach source points (waypoints) in an automated fashion. There are dozens of sensors monitoring the engine operation, hydraulic systems, drive systems, etc. These monitoring systems also provide a window into critical functions of the vibroseis—monitoring engine dynamics, fluid levels and pressure, and many others. Using computers, NEUROtec provides condition-based alerts and prompts significantly reducing the burden on the vehicle operator. Through NEUROtec’s record logs, historical data can be used to examine performance of fleets and identify vibroseis units that need maintenance or repair before issues become critical. Akin to certain automotive platforms, NEUROtec allows INOVA to extend vehicle capability even after vehicles are deployed with little to no cost to operators.

E&P: Do you have any recent case study details to share?

Selvakumar: The AHV-V TITAN vehicles with this technology are being used in the Gulf region in a high-productivity, seismic survey employing 10-plus fleets over the past year. These NEUROtec-enabled vehicles have helped the customer achieve their high-productivity goals and operational confidence due to the advanced features mentioned earlier. In the new COVID-19 world where international travel has been severely restricted, identification and correction of issues can be performed remotely without INOVA personnel on the ground.

E&P: With a large focus on ESG, how does this technology meet current needs to be environmentally friendly and reduce HSE risks?

Selvakumar: Environmental and social governance is another area where INOVA has been actively researching and developing products and methods that enhance modern vibroseis. Digital control and monitoring systems are enabling technologies that allow scrutiny of any function of the vibroseis that is critical to safety and operations. These include systems such as cameras and imaging technology that help with blind spot coverage, obstacle detection and avoidance. Cameras are outfitted within the NEUROtec framework to detect fuel, oil and hydraulic fluid spills from the vehicle and take corrective action to avoid impacting the environment as well as avoid expensive downtime and remediation penalties on the operator.

In addition, a digital vibroseis infrastructure is used to ensure the driver is wearing a seatbelt or induce other user-required prerequisites before driving or operating the vibroseis. NEUROtec also reaches other areas of the vibroseis, such as interfacing to new engine technologies that require less fuel, generate more horsepower and reduce ambient noise generation. They also come with specific enhancements such as low-sulfur fuel requirements and emission standards that meet current and future regulations.

E&P: Is there any additional work planned to put into development and/or additional industry applications it might have beyond those defined in your scope of work?

Selvakumar: We have several projects underway with one being to safely automate the synchronization of the vehicular movement and stoppage versus the seismic actuation function. This requires safety protocols to be followed and avoid automation pitfalls that could be encountered when aspects of human intervention are bypassed. Another project is to strengthen the level of vehicle health and QC [quality control] monitoring, logging, parsing and presenting trend information such that predictive maintenance can be undertaken. NEUROtec’s objectives aim to provide a safer and cleaner operating vibroseis coupled with lower cost and better controlled operations. In summary, continued development of NEUROtec technologies are well underway and geared toward a new generation of vibroseis that provide significant value and benefits to contractors, operators and their ultimate customers.

E&P: As an expert in this field, what do you see as the path forward for seismic and exploration technology?

Selvakumar: With year-on-year pressure on exploration capital budgets of major oil companies, there is increased pressure on equipment providers to lower system pricing, which has increasingly commoditized the product offerings. There is diminishing opportunity for significant cost reduction in this space. Going forward, the focus will and should shift from the equipment assets to the operational improvements. This will be directed at reducing the surveying operational costs, turnaround time and operational speed, improvement of health and reduction of the safety risk exposure and reducing the environmental impact of the operation as fossil fuel exploration gets increased scrutiny from governmental and societal stakeholders. The seismic service and equipment providers will need to increasingly work together and within these fast-changing boundary conditions to achieve these goals and provide an effective solution.

Recommended Reading

Canada Likely to Delay Trans Mountain Pipeline Sale

2024-07-26 - The Canadian government will likely stall the sale of the Trans Mountain oil pipeline until after the national election in 2025.

Report: TC Energy Close to Selling $726MM Pipeline Stake to Indigenous Groups

2024-07-24 - The Canadian government has given preliminary approval for a loan to indigenous groups to buy a stake in TC Energy’s NGTL pipeline system.

Alaska Approves Plan to Build $56.6MM Pipeline for LNG Imports

2024-07-24 - Natural gas utility Alaska Pipeline Co., an affiliate of Enstar Natural Gas, received approval from the state to build the 16-mile pipeline, which will be connected to a terminal at Port Mackenzie, near Anchorage.

Private Equity Firms Buy Pipe-coating Company MCIP

2024-07-23 - Milestone Capital and D2 Equity Capital acquired purchased a majority interest in family-owned pipe-coating business MCIP.

Williams Begins Louisiana Project Despite Lingering Legal Dispute

2024-07-22 - Williams Cos. Informed FERC that the Louisiana Energy Gateway project will begin construction despite an ongoing dispute with midstream rival Energy Transfer.