From a North Sea discovery to a $2.4 billion water treatment project, below is a compilation of the latest headlines in the E&P space.

Activity headlines

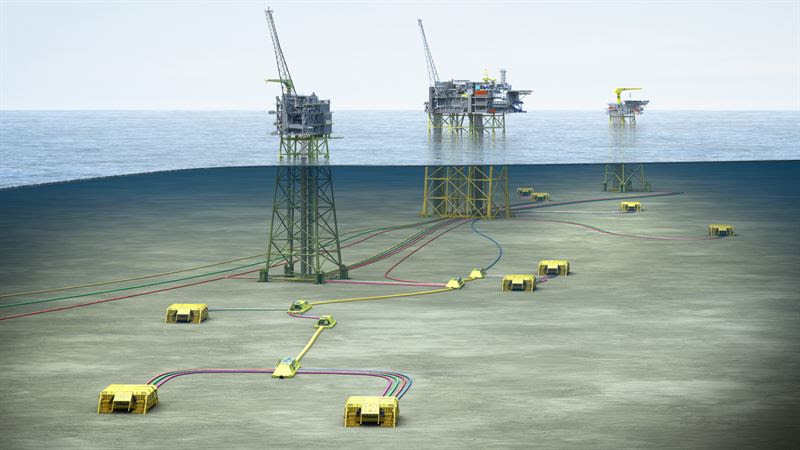

Find Ups Yggdrasil Possibilities

Aker BP reported a significant oil discovery with its Øst Frigg Beta/Epsilon exploration well in the Yggdrasil area of the Norwegian North Sea.

On May 25, Aker BP said preliminary estimates of the well in PL 873 and PL 442 indicated gross recoverables of between 40 million barrels of oil equivalent (MMboe) and 90 MMboe. Pre-drill estimates had ranged from 18 MMboe to 45 MMboe.

Aker BP said the find enhances the resource base for the Yggdrasil development, which was previously estimated at 650 MMboe. At the end of 2022, Aker BP submitted a plan for development and operations (PDO) to Norwegian authorities, with production scheduled to begin in 2027.

Aker BP said it will evaluate the find as a potential addition to Yggdrasil.

Aker BP operates PL 873 with 47.7% interest on behalf of partners Equinor with 40% and PGNiG Upstream Norway with 12.3%. Aker BP operates PL 442 with 87.7% interest on behalf of PGNiG with 12.3% interest.

Enauta Adds to Atlanta Reserves

Enauta Participações SA announced May 23 it had confirmed oil through the 9-ATL-8DP well in a new reservoir section, the Atlanta NE accumulation, offshore Brazil.

Atlanta NE is in the larger Atlanta Field, which is under development. Enauta estimates resources in place exceed 230 MMbbl. Drilling and logging of the well are complete, and more studies are planned.

Enauta is developing the Atlanta Field in 1,500 m water depth with an FPSO. The six wells connected to the FPSO Atlanta are expected to produce up to 50,000 bbl/d, with Phase 1 first oil expected in mid 2024.

Contracts and company news

Aker BP signed a contract with Heerema Vlissingen on May 23 for the Munin jacket in the Yggdrasil area of the North Sea, Aker BP said on May 25.

Munin will be an unmanned production platform in the northern part of the Yggdrasil area in the North Sea. Aibel is delivering the topsides.

Aker BP’s Peter Kupka, project director for fixed facilities deliveries in Yggdrasil, said the Munin jacket award is the final major fixed facilities contract to be awarded for the project.

Aker Solutions will handle detailed engineering of the jacket, which will be fabricated at the Heerema yard in Vlissingen in the Netherlands. Jacket procurement will start in the autumn, and construction is set to start in the beginning of 2024. Installation is set for 2025.

The Munin jacket will be 130 m high and weigh 5,800 tonnes. Eight 60-m piles will be used to secure the jacket to the seabed in water depth of 105 m.

Yggdrasil consists of the Hugin, Fulla and Munin license groups. The area contains a total of around 650 MMboe. Final investment decision (FID) for the Yggdrasil area came in December 2022, and total investments are estimated at $10.4 billion.

$2.4B Water Treatment Project Planned

ADNOC and Abu Dhabi National Energy Co. PJSC (TAQA) announced on May 24 they had awarded a $2.4 billion strategic investment project to provide sustainable water for ADNOC’s onshore operations.

The project calls for a centralized seawater treatment facility and transportation network for operations at the Bab and Bu Hasa fields in Abu Dhabi. This project will replace the current high-salinity, deep aquifer water systems at the fields, reducing water injection related energy consumption by up to 30%, the companies said. The project will be connected to the grid.

ADNOC and TAQA will each hold 25.5% in the project company, with the remaining 49% stake awarded to a consortium of Orascom Construction and Metito.

The project will deliver more than 110 million imperial gallons per day of nano filtered seawater through 75 km of transportation, 230 km of distribution pipelines and two pumping stations.

Partners in Kenya Block Back Out

Two companies are withdrawing from Tullow Kenya-operated licenses in the South Lokichar Basin in Kenya, Tullow Oil reported May 23.

With TotalEnergies and Africa Oil each pulling out of Blocks 10BB, 13T and 10BA, Tullow’s operated interest moves from 50% to 100%. In a press release, Tullow said the partners, which each held 25% interest, were pulling out of the block for “differing internal strategic reasons.”

Africa Oil President and CEO Keith Hill said in a press release that the company was exiting the Kenya concessions because “our strategy has shifted to focus on production and high potential exploration opportunities, including our Orange Basin portfolio where we are now appraising the exciting Venus discovery offshore Namibia.”

For its part, Tullow said that full ownership of the project offers more optionality and flexibility, as well as streamlining project delivery. Tullow said it is seeking a strategic partnership this year for the blocks and believes the withdrawal of its partners will create a simpler partnership model.

The Kenyan regulator, Energy and Petroleum Regulatory Authority (EPRA), is reviewing the updated field development plan, which Tullow submitted in March.

TechnipFMC Picked for Dover Tieback

TechnipFMC announced on May 25 that it won an integrated engineering, procurement, construction and installation (EPCI) contract from Shell Plc for its Dover subsea tieback in the Gulf of Mexico (GoM).

Under the deal, TechnipFMC will supply the subsea tree systems in addition to the EPCI of the umbilical, riser and flowline systems.

Dover will tie back to the Appomattox platform, for which TechnipFMC supplied and installed the subsea production systems.

Aquaterra Wins Cypre Riser Work

Aquaterra Energy announced May 23 that it secured a subsea riser contract for BP’s Cypre subsea project in Trinidad and Tobago.

Under the contract, Aquaterra will deliver the Cypre subsea riser system, which will be operated from a jackup rig. It will support gas exploration from seven development wells in about 80 m of water. Drilling activities are expected to commence in 2023 with gas production to begin in 2025.

IKM to Survey Kraken FPSO for Emissions

IKM Testing UK announced May 23 it secured a second contract with Bumi Armada to deliver a drone-based methane emissions survey on the Kraken FPSO in the North Sea. In November 2022, an aerial survey established baseline methane emissions from the Kraken FPSO.

IKM delivered a breakdown of the methane emissions measured during the first project, including an overall asset methane value and localization of methane emissions hot spots. The second drone survey is set to begin in third-quarter 2023 and will see IKM build on the results from the initial work.

Bumi Armada will use the results to inform its Methane Action Plan, with the overall aim of reducing methane emissions from the Kraken FPSO.

Trendsetter Tapped for Guyana Connectors

Trendsetter Engineering Inc. announced May 23 it won a contract to provide Esso Exploration and Production Guyana Ltd. with TC11 Connection Systems for the Gas-to-Energy project in Guyana.

The contract includes Trendsetter’s TCS subsea connectors, hubs and an assortment of pressure caps and tooling. The contract also includes subsea valves, sourced from Advanced Technology Valve (ATV) in Italy. The equipment is slated for delivery in mid 2023.

Rig Extended Offshore Namibia

Northern Ocean said on May 25 that Shell had extended the contract for the Deepsea Bollsta, which has been drilling offshore Namibia, by six months from December 2023 to June 2024. The extension, which includes an option for six additional months, is valued at $88.6 million.

In April, the Deepsea Mira left Norway, bound for Namibia, where it will mobilize for multi-country work for TotalEnergies. Northern Ocean said the rig had experienced delays

loading equipment and performing required maintenance during the transit. The company expected to begin the contract at the end of second-quarter 2023.

Halliburton Adds Odessa Lab

Halliburton has opened a regional laboratory in Odessa, Texas, to serve Multi-Chem customers in the Permian Basin region, the company said on May 23.

The facility includes a team of scientists and lab personnel who can analyze oilfield samples and deliver data-driven insights to technical and field teams, Halliburton said.

“We are also working to link this lab system with customers’ databases to enhance insights, assess risks and drive program performance,” said Jacob Hardy, Halliburton’s North America land region manager.

2H Launches Wellhead Fatigue JIP Phase 2

2H Offshore announced on May 23 it was launching the second phase of its measurement-based wellhead fatigue joint industry project (JIP).

The JIP aims to improve riser, wellhead and conductor fatigue estimates and make drilling operations more reliable and efficient.

In Phase 1 of the project, 2H collaborated with nine major operators to gather and analyze field measurements from ten drilling campaigns in the GoM and the North Sea. The data covered a range of environments, water depths, soil characteristics, riser and wellhead configurations and vessel types. Findings from the analysis verified that industry assumptions for wave and vortex-induced vibration fatigue assessments are conservative. Remaining fatigue life tends to be higher than determined by typical design methods. A more accurate prediction of remaining fatigue life can eliminate the need for costly mitigation methods or unnecessary upgrades and downtime during severe events.

In the second phase, the field data analyzed in Phase 1 will be used to explain uncertainties identified in the riser, wellhead and conductor fatigue analysis. The findings are expected to further improve the accuracy of future wellhead fatigue assessments and provide an industry consensus on design methodology, 2H said.

Harbour Energy Extends Stork Services

Fluor Corp. announced on May 24 a five-year contract with extension options with Harbour Energy.

The deal extends Fluor company Stork’s asset integrity services in the North Sea to Harbour Energy’s Armada, Everest, Lomond and Erskine (AELE) hub, and also extends services to Solan, the J-Area and the Great Britannia Area.

Under the new contract, Stork will deliver asset integrity planning, inspection, fabric maintenance, access solutions, hot bolting and composite repair applications. Stork will also provide deck crew services across the AELE hub.

OMV Continues CGG Center

OMV has awarded CGG a new contract to continue operating a dedicated center at its head office in Vienna for an initial three-year period, CGG said on May 23. During this time, OMV will have in-house access to CGG’s seismic imaging and reservoir characterization technology, as well as its multi-disciplinary geoscience expertise, CGG said.

University Offers Apps for MMP, Viscosity Calculations

A team of University of Houston researchers has developed a series of digital applications to make energy industry processes more efficient. The team announced on May 25 that the three online calculators — the most recent being the UH Hydrocarbon Gas Minimum Miscibility Pressure (MMP) Calculator — are available to industry professionals for free.

The new calculators for hydrocarbon MMP, carbon dioxide MMP and viscosity, can help engineers in the field save time, resources and funds by enabling faster screenings and calculations, the team said. The team is comprised of Birol Dindoruk, the American Association of Drilling Engineers Endowed Professor in petroleum, chemical and biomolecular engineering at UH; Mohamed Soliman, chairman of the UH Department of Petroleum Engineering; and Utkarsh Sinha, who earned a master’s degree in petroleum engineering from UH in 2018.

“We don’t want our ideas and findings to just exist on paper,” Dindoruk said. “We want our tools and techniques to be deployed and used by others to improve the efficiency of these processes.”

By making the apps freely available, the researchers hope to learn from users’ feedback to make improvements and develop new applications.

The UH Viscosity Calculator app calculates the thickness of crude in its natural state, also known as dead oil, needing very little information. It is a full-range method, which can measure a wide range of oil viscosity – from a fraction of centipoise (cp), a unit measurement of viscosity, to a million cp.

The UH Carbon Dioxide MMP Calculator considers the composition and temperature of the oil as input parameters. The proposed hybrid model performs better than existing correlations and machine-learning methods, covering a wide range of MMP values, Dindoruk said.

The UH Hydrocarbon MMP Calculator uses a model called light gradient boost to estimate the MMP for hydrocarbon gas injection. The team also determined the minimum amount of heavier hydrocarbon gas needed to reach the target MMP.

“This helps achieve the desired pressure without needing expensive compressors or risking damage to the reservoir,” Dindoruk said.

Regulatory updates

BSEE Oversees Capping Stack Drills

The Bureau of Safety and Environmental Enforcement (BSEE) said a pair of unannounced equipment deployment drills aimed at evaluating the oil and gas industry’s preparedness to respond to a subsea blowout were successfully completed.

The drill for Beacon Offshore Energy (BOE) started on May 7 and ran through May 10, while Chevron’s started May 19 and ended May 23. The drill called for the operators and their mutual aid partners to deploy and install equipment to cap a blowout in deep water off the coast of Louisiana.

The operators had to deploy a capping stack — which is source control equipment designed to shut off any oil flow from a well if other systems fail, such as the blowout preventer — from their respective storage locations near Houston and Corpus Christi, Texas, to separate areas in the GoM. Once on site, each operator lowered a capping stack onto a simulated wellhead on the ocean floor in about 6,000 ft of water, connected the capping stack to the wellhead, and pressurized the system to 12,500 pounds per square inch to simulate well pressure.

While initial observations indicate the drills met BSEE requirements for deploying source control equipment, BSEE said it will evaluate all aspects and results of the drills and make recommendations in a formal report later this year.

Recommended Reading

Dividends Declared Week of Nov. 4

2024-11-08 - Here is a compilation of dividends declared from select upstream and midstream companies in the week of Nov. 4.

TC Energy Appoints Two Independent Directors to Board

2024-11-07 - TC Energy Corp. appointed Independent Directors Scott Bonham and Dawn Madahbee Leach to its board, the company announced Nov. 7 in a press release.

OMS Energy Files for IPO, Reports Revenue Growth

2024-11-06 - Singapore-based OMS Energy, a wellhead system manufacturer, has not yet determined its price range and number of shares.

Record NGL Volumes Earn Targa $1.07B in Profits in 3Q

2024-11-06 - Targa Resources reported record NGL transportation and fractionation volumes in the Permian Basin, where associated natural gas production continues to rise.

Twenty Years Ago, Range Jumpstarted the Marcellus Boom

2024-11-06 - Range Resources launched the Appalachia shale rush, and rising domestic power and LNG demand can trigger it to boom again.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.