Presented by:

Editor's note: This "Tech Trends" section appears in the new E&P newsletter. This weekly section highlights the latest upstream technologies and services for the oil and gas industry. The copy herein is compiled from press releases and product announcements from service companies and does not reflect the opinions of Hart Energy. Submit your company’s updates related to new technology products and services to Ariana Hurtado at ahurtado@hartenergy.com. Subscribe to the E&P newsletter here.

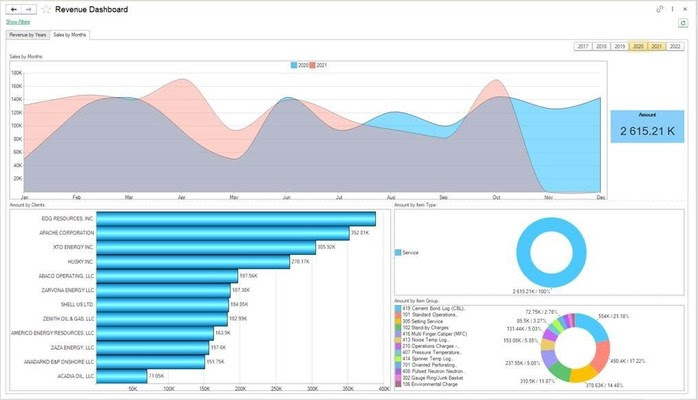

System connects entire organizations through data and delivers real-time insights

Zeno Technologies has released a cloud-based platform to help energy companies, investors and partners drive business performance in the face of new market realities of the production era. Today’s energy-focused businesses need modern tools to unlock data to inform smarter, faster business decisions. Zeno’s Energy Operating System provides the clarity to understand and improve business performance as well as the insight to decisively assess and pursue new investment opportunities. Energy businesses once valued on land potential and top-line growth are now measured on production efficiency and bottom-line free cash flow. This fundamental shift in valuation underscores the importance of optimizing business performance and maximizing productivity. While today most energy-focused organizations base critical business decisions on a patchwork of disparate, legacy data tools, this technology connects entire organizations through data and delivers real-time insights to run their businesses on real numbers, not best estimates.

Digital field ticketing and asset management for oilfield rentals and service industry

RigER Inc. has released advancements to its mobile field ticketing and asset management technology, RigER. It is designed to transform the oilfield service industry by transforming oilfield rental and service operations into a scalable digital enterprise at a cost that meets a midsize company budget. The updated version of RigER has additional capabilities to connect offices, shops, yards and field crews. Latest additions include a secure customer web portal where oilfield service companies can share information about jobs directly with E&Ps; an added QR code to speed up checking in and out equipment, running inventory control and accessing full equipment history, eliminating manual data entry; new configurations designed specifically for trucking and water hauling operations; direct integration with OpenInvoice; an added project management dashboard; an improved job calendar; a rental unit dashboard; and a truck dashboard. With fast implementation, companies can run the new system and start getting benefits in a few months.

Companies enter alliance to develop CCS solutions

TechnipFMC and Talos Energy Inc. have entered into a long-term alliance to develop and deliver technical and commercial solutions to carbon capture and storage (CCS) projects along the U.S. Gulf Coast. The alliance combines Talos’ offshore operational strength and subsurface expertise with TechnipFMC’s extended history in subsea engineering, system integration and automation and control. The alliance was cultivated through a shared vision to responsibly deliver CCS solutions that will accelerate offshore CCS adoption with reliable, specialized CCS systems. Under the alliance, the companies will collaborate to progress CCS opportunities through the full life-cycle of storage site characterization, FEED and first injection through life-of-field operations. This further advances the companies’ leadership in the emerging Gulf Coast CCS market, building on Talos recent successful award as the operator of the only major offshore carbon sequestration hub in the U.S.

Solids control tech reduces emissions by 43% onshore and 42% offshore

Cubility’s MudCube solid control tool reduces waste treatment emissions associated with drilling by 43% onshore and 42% offshore compared to traditional shale shakers. Based on a report commissioned by the company, Cubility estimates that its customers saw CO2 emission reductions of 21,221 mT and 13,037 mT in waste reductions during 2020 with the technology as compared to traditional shale shakers. The report also calculated that the reduction in waste treatment emissions through the product when landfilled would be 75% onshore and 76% offshore compared to shale shakers, and there was a 35% reduction in actual waste. Launched by Cubility in 2012, the MudCube is the first fully enclosed, lightweight solid control system for all types of drilling fluids, providing an alternative to traditional shale shakers. It uses light vibration with high air flow through a rotating filterbelt to separate all types of drilling fluids from drilled solids.

Perflouroelastometer for oil and gas applications

DuPont has released Kalrez OG193 perfluoroelastomers, a 95 durometer, FFKM compound that balances properties for oil and gas applications. It combines rapid gas decompression performance and chemical resistance with good low temperature and thermal stability. It passes the acceptance criteria for multiphase sour aging according to ISO23936-2 and scores the highest rating at the rapid gas decompression test. It is an ideal fit for various applications in both upstream and downstream, such as oilfield production/completion equipment, wireline and drilling tools, pumps, mechanical seals, valves and compressors. Manufacturers, contractors and well operators need to operate with equipment purposefully developed to resist harsh environments and offer a margin for safety. The technology offers versatility without compromise for a variety of key parts including O-rings, packers, bonded seals, chevron stacks, T-Seals and many other applications including production and completion equipment, pumps, valves, compressors and mechanical seals.

Technology for all hydrogen applications

Tenaris has released THera, its latest materials technology for all hydrogen applications. The technology offers robust, high-strength materials with a verified fatigue life and reliable performance in hydrogen environments. THera applications include hydrogen storage systems for refueling stations that are designed for pressures in the range of 240 bar up to 1,000 bar and tube trailers with customized dimensions and lengths to optimize design for reliable hydrogen transportation. It also comprises solutions for industrial segments such as refineries, hydrocarbon processing, steel shops and green/blue processing. The technology also allows to transport safely up to 100% hydrogen gas in high pressure, onshore and offshore transmission pipelines.

Removal of 348 kg of solids in desander project in Trinidad

FourPhase has announced the first-ever successful desander operation in the wider Trinidad region. The operation was successfully completed without safety or operational incidents for one of the major oil and gas operators in the region. During production, the well experienced a heavy accumulation of solids in the injection line resulting in a well shut-in. When the gas-lift valve was pulled from the lowest gas-lift station, debris from the A annulus entered the tubing. A coiled tubing operation was selected as the best course of action to clean out the solids, pull the plug and gain access to the lower zone. This was the first time a desander was used in Trinidad, and the DualFlow 5K cyclonic separation system was selected as the best technology to undertake the job. FourPhase deployed a suite of its own products including the DualFlow 5K desander, flow meter manifold, dual choke manifold, Surface Safety Valve and FourPhase production specification pipework.

Collaborating companies announce courses that simulate real-world environments

Endress + Hauser and the Petroleum Extension (PETEX) will collaborate to provide training courses starting in fall 2021. PETEX will host courses at Endress + Hauser’s Houston campus and will use the manufacturers’ process training unit (PTU). The PTUs are full-scale, working process skids with functional instrumentation and controls, closely simulating a real-world environment. Trainees will gain hands-on experience with the types of configurations, operations, diagnostics and troubleshooting found in actual process plants and facilities. This specific PTU features working gas and liquid systems and is equipped with more than 200 modern Endress + Hauser devices, along with a variety of the latest instrument configurations, communication protocols and software. PETEX is a unit of the Cockrell School of Engineering at the University of Texas at Austin.

Companies partner to accelerate clean energy transition

Petrolern LLC, a clean energy technology and services company, has formed a partnership with Stratagraph, a provider of geological services to the oil and gas industry. This alliance encompasses geothermal energy, carbon storage and cleaner oil and gas. Petrolern is a technology company with capabilities in real-time characterization, monitoring and visualization of subsurface formations. With the combined efforts of both Stratagraph's experience in the geological service sector and the subsurface engineering and digitalization offerings of Petrolern, the organizations will work in tandem with the goal to make a difference in the energy industry and help accelerate the clean energy transition. The partnership has a broad scope of impact, including research and consulting projects, training, software development and field operational services. It effectively integrates capabilities in geomechanics, geology and artificial intelligence.

Pump-per-point synchronous lift system for heavy lifting

The Enerpac EVO-P Pump-Per-Point Synchronous Lift System provides speed and accuracy for heavy lifts. As a pump-per-point system, it features individual hydraulic pumps for each lifting point. This reduces distance from pump to cylinder, minimizing hose lengths and risk of leaks. The hydraulic pumps are two-stage, which is ideal for fast retraction and repetitive operations. The combination of a higher flow rate per cylinder and high accuracy means lift is completed sooner without sacrificing quality. The system has an improved speed option for large cylinders with longer strokes. Due to its high oil capacity in each cylinder, it eliminates the need for custom reservoir designs. The variable frequency drive (VFD) motor controls lifting accuracy and minimizes starts and stops, resulting in faster and smoother lifts, which is ideal for sensitive structures. The VFD speed control allows flexibility when using multiple cylinder capacities on the same lift.

Recommended Reading

US Oil Rig Count Rises to Highest Since June

2025-04-04 - Baker Hughes said oil rigs rose by five to 489 this week, their highest since June, while gas rigs fell by seven, the most in a week since May 2023, to 96, their lowest since September.

Black Gold, LGX Find Multiple Pay Zones in Western Indiana

2025-04-04 - Black Gold Exploration Corp. and LGX Energy Corp. are working to start production at the Fritz 2-30 oil and gas well in Indiana within 60 days.

Pennsylvania City to Turn Coal-Powered Plant into Gas-Fired Data Center Campus

2025-04-03 - Construction on the Homer City Generating Station is expected to start in 2026.

BP’s Cypre Development Off Trinidad and Tobago Delivers First Gas

2025-04-03 - BP Trinidad and Tobago said the Cypre development is projected to deliver approximately 45,000 boe/d at peak.

Sitio Fights for its Place Atop the M&R Sector

2025-04-02 - The minerals and royalties space is primed for massive growth and consolidation with Sitio aiming for the front of the pack.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.