When oil prices are low, the industry is challenged to seek opportunities to optimize every producing asset. On the production side, it is the production engineer’s mission to design the most cost-effective means to recover the greatest amount of production from a well in the shortest amount of time. Conventional artificial lift practice often transitions a horizontal well through multiple artificial lift systems in a strategic attempt to balance lifting reliability and maximize drawdown, all while trying to achieve the lowest possible operating costs. The artificial lift predicament is this challenge to simultaneously maximize drawdown and achieve reliability.

Gas-lift limitations

Once horizontal wells expend their phase of natural flow and an artificial lift system is required, they are known to have production challenges associated with downhole pump gas interference and solids issues. Gas lift often is implemented as a transitional artificial lift solution since it is solids-tolerant, can handle high decline rates and can manage sluggy flow conditions inherent to horizontal wells. Producing fields with gas infrastructure frequently default to this option to capitalize on existing equipment but knowingly sacrifice longer term production and reserves from the limitations of gas lifting.

In the artificial lift predicament, gas lift addresses reliability, but its downfall and limitation is the difficulty of achieving a low producing bottomhole pressure (BHP) to maximize drawdown. To complicate the challenge, gas lift is a highly inefficient process, and the deeper the well, the more limited drawdown becomes.

For example, in a typical 2,000-m (~6,500-ft) true vertical depth (TVD) horizontal well, the lowest producing BHP a gas-lift system can achieve is about 750 psi. Limiting producing BHP to 750 psi results in the well not being produced to its full potential. At some point in the life cycle the well will be forced to move from gas lift to another artificial lift solution such as rod pumping to further increase drawdown and produce at a rate that can economically access the remaining reserves.

Reliability and drawdown

Rather than finding the trade-off balance between reliability and drawdown, consider a way to drive both. Production Plus Energy Services Inc. took on this challenge and identified the root cause of the reliability drawdown trade-off: sluggy, inconsistent messy flow from the horizontal. Traditional artificial lift systems struggle when faced with horizontal wells that present rapidly fluctuating fluid rates and surges, solids issues and gas interference. The consequences of this messy flow are poor runtime, excessive workover costs and inadequate drawdown.

Researchers discovered that the key to the artificial lift predicament in horizontal wells is to smooth flow. The company developed the patent-pending Horizontal Enhanced Artificial Lift System (HEAL) to complement existing artificial lift systems. It settles the messiness of horizontal flow and reduces fluid density to lift fluids up to the vertical where a pump can operate reliably. The system controls solids and gas interference to protect the pump while operating at very low producing BHPs.

The system itself is a mechanical system comprised of a seal, a sized regulating string and a highly efficient vortex separator. To minimize operational risk, the system was designed with no moving parts and does not extend into the horizontal.

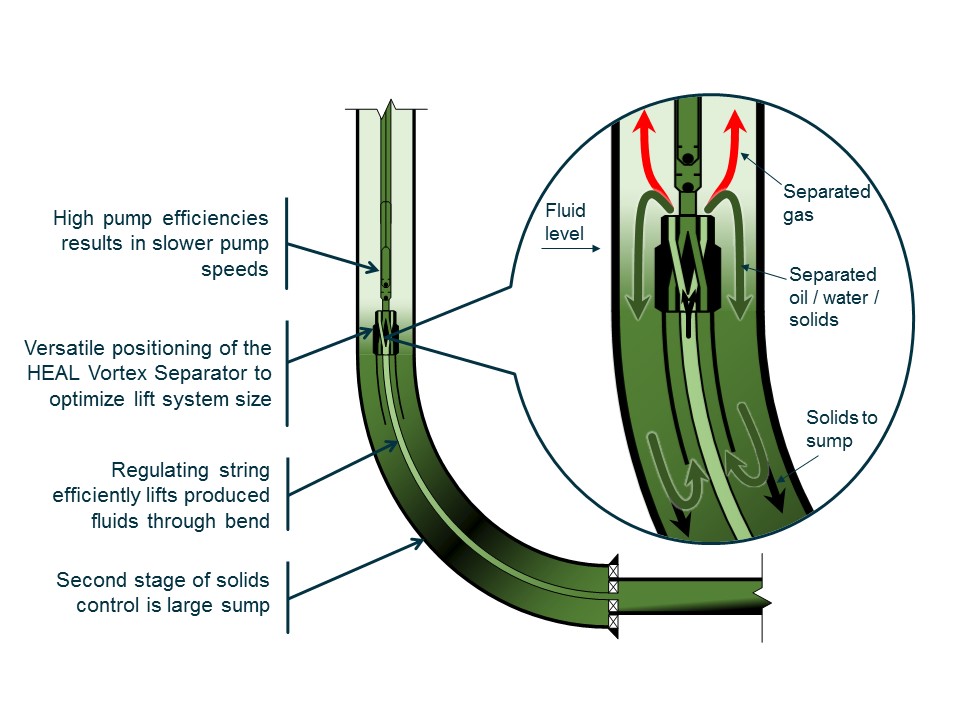

Production from the horizontal is conditioned up the sized regulating string, smoothing flow and reducing density, which results in increased drawdown. Flow from the sized regulating string is discharged to the well’s annulus by the vortex separator, which is placed near or above the kickoff point. The cyclonic effect of the vortex separator efficiently separates gas and solids from the liquid, protecting the pump from gas interference, damage or seizing from solids (Figure 1).

Smooth, even flow of liquid to the pump creates the possibility for exceptional reliability. Reliability is directionally proportional to higher pump efficiencies at slower pump speeds and reduced pump loads—a combination that sets the stage for resolving the predicament of reliability and maximized drawdown.

Case study

The Western Canadian Sedimentary Basin is no stranger to the artificial lift predicament, including a west-central Alberta well in the Montney zone. This horizontal multistage fractured well had a total measured depth of 4,202 m (13,786 ft) at a TVD of 2,441 m (8,008 ft). The well had a high gas-liquid ratio, starting at 34 cu. m/bbl (1,200 scf/bbl) and rising to more than 99 cu. m/bbl (3,500 scf/bbl) as production proceeded.

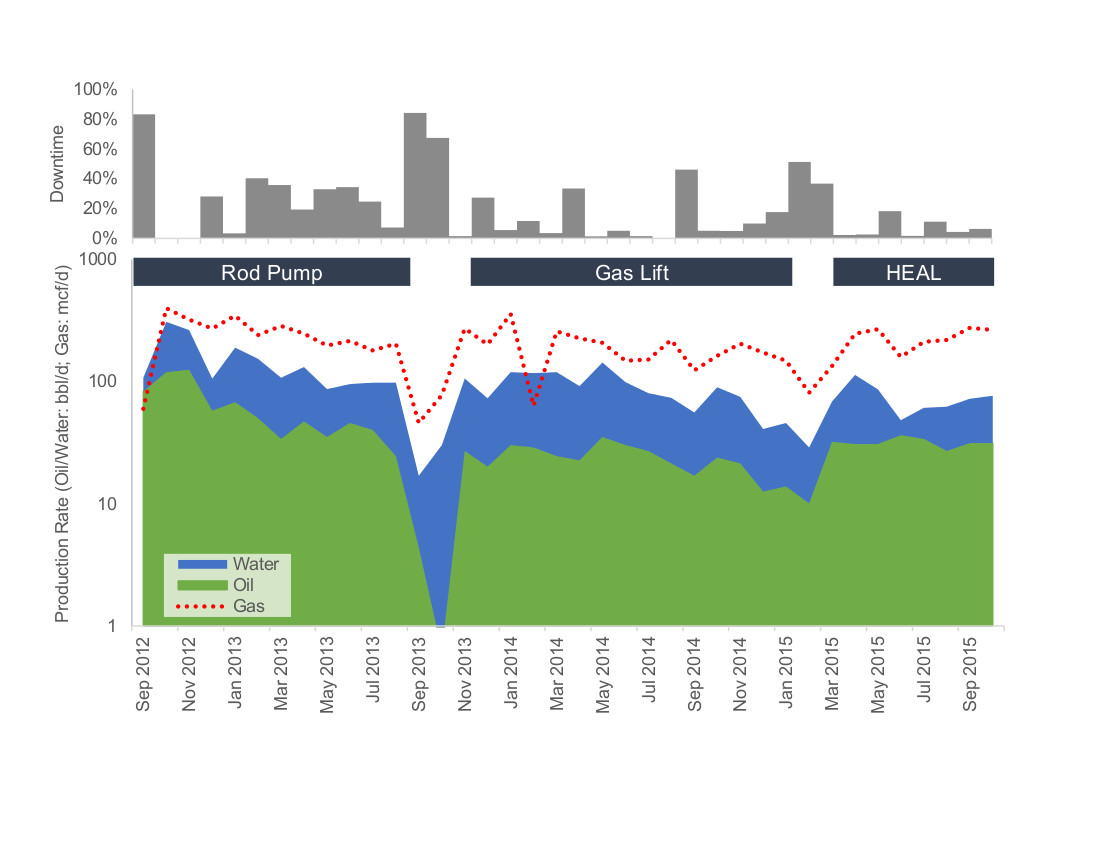

Initially, the operator installed a rod pump that was plagued by runtime challenges and inefficiencies caused by gas interference, averaging monthly downtime of 25%. Gas lift was installed with the expectation of higher production runtime. Gas lifting did provide a solution for reliable production runtime (Figure 2). It reduced the average monthly downtime to 12%. However, drawdown was significantly compromised so that instantaneous production rates diminished by 10% to 15%. Higher runtime realized from gas lift offset the production decrease to keep total fluid rates from the well on trend with earlier rod pump production. The operator was caught in the predicament of balancing reliability against the quest for more drawdown by achieving a low producing BHP.

Beyond the artificial lift predicament, the cost of achieving additional runtime was substantial. The operator had to install the gas-lift equipment and support increased operating costs. Monthly operating cost for gas lift are typically $20,000, while rod pumping operating costs are about $8,000 per month.

The HEAL System was introduced to replace gas lift and return the well to rod pumping. The system was placed downhole below the rod pump in the bend section of the horizontal. Placing the system in the bend allowed the pump to be placed above the kickoff point and into the vertical part of the wellbore, requiring a smaller pumpjack. A conventional installation in this field would require a larger pumpjack and rodstring to achieve the same production rates that the system achieved with the smaller pumpjack.

Produced fluids were efficiently lifted through the bend, achieving lower producing BHPs at greater reliability than previously realized with earlier artificial lift systems installed in this well. The production and value-add benefit to the well continues to be substantial.

Changing the mindset

As the price of oil is remaining low for the foreseeable future, it is becoming increasingly difficult for operators to retain operating margins and to reconcile the artificial lift predicament. In this case study the operator was able to realize the well’s potential by shifting out of the traditional artificial lift approach. With the installation of the HEAL System, the operator was able to complement a current system and capitalize on existing equipment as well as create a situation where the well reliably maximized drawdown and lowered operating costs simultaneously.

Recommended Reading

Apollo to Buy $1B Stake in BP’s Trans Adriatic Pipeline

2024-09-16 - Apollo will purchase the non-controlling interest from BP subsidiary BP Pipelines TAP Ltd. for $1 billion as the oil major continues to make progress on a divestment target of up to $3 billion.

Apollo Closes $1.85B Take-private Acquisition of U.S. Silica

2024-08-01 - Following Apollo’s acquisition of U.S. Silica, the company will be led by current management and CEO Bryan Shinn.

US Silica Investors OK Apollo’s $1.85B Take-private Deal

2024-07-16 - U.S. Silica stockholders approved a $1.85 billion all-cash deal with Apollo Global Management, a transaction that will take publicly traded proppant services provider private.

EQT Closes $5.45B Acquisition of Equitrans Midstream

2024-07-22 - In addition to integrating Equistrans’ midstream assets, EQT will focus on reducing the infrastructure company’s debt of between $7.6 billion and $8 billion. Including equity and debt, the deal is valued at roughly $13 billion.

NOG Updates Share Buyback Following Point Energy Purchase

2024-07-30 - Northern Oil and Gas repurchased 895,076 shares of common stock during second-quarter 2024 at an average of $38.96 per share.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.