(Source: API)

Ten years ago, API collaborated with American Fuel & Petrochemical Manufacturers (AFPM) to develop the Process Safety Site Assessment Program (PSSAP®) for refinery, petrochemical, and chemical facilities as part of the industry’s continual effort toward achieving zero incidents.

Since the program was launched, PSSAP has grown into a vital industry tool to enhance process safety performance—a broad safety framework based on sound design principles, engineering, operating and maintenance practices.

PSSAP helps operators improve safety performance through assessments that facilitate feedback from expert assessors, peer benchmarking and collaboration to improve operations. The program has generated a substantial amount of blinded and anonymized data to facilitate knowledge sharing among operators, with API completing more than 155 assessments globally.

The industry’s focus on process safety performance has led to a significant decrease in incidents over the past decade. Through use of API standards and participation in safety programs such as PSSAP and other industry good practices, the Tier 1 Process Safety Event rate rolling average, which is recognized by the industry as an indicator of key operational performance, has declined by more than 50% for U.S. refineries from 2011 to 2020, according to an API survey.

Developed by industry for industry, PSSAP involves the assessment of a site’s process safety systems by third-party teams of industry-qualified process safety expert assessors. A major strength of PSSAP comes from the participation of these assessors, who are leaders in the field with an average of 40 years process safety experience in the refining and petrochemical industry.

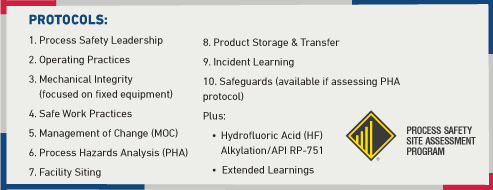

Based on ten protocols, PSSAP assessments leverage industry-supported good practices and are guided by more than 100 API standards. During an assessment, API assessors spend a week on site, evaluating a facility’s written management system as well as implementation of each of the protocols, scoring each requirement. The scoring in each of the protocols allows API to create benchmarking from assessments, resulting in a final report consisting of detailed observations about the 600 requirements contained in the protocols that allow a site to pinpoint specific areas which may need more attention within their process safety management system.

PSSAP highlights the industry’s effort and commitment to enhancing world-class process safety performance metrics and practices, although assessments do not satisfy regulatory auditing requirements—with the exception of Hydrofluoric Acid Alkylation/ API Recommended Practice 751.

Operators say PSSAP and its assessors provide expert input to enhance process safety performance across facilities through feedback, knowledge sharing of good practices, and implementation of improvements.

“PSSAP is an invaluable tool to test the strength of site management systems against industry good practices, and it is clear the API assessors are invested in sharing these practices with the site to help prevent process safety incidents,” said John Elmore, Shell Geismar’s process safety manager.

"The wealth of industry experience held by the assessment team was truly impressive and is key to the value of the API PSSAP. The assessors’ thorough review of site practices and open interaction with site personnel provided clear direction for our process safety journey and has resulted in tangible improvements across the refinery,” said Greg Lucchesi, Motiva’s Vice President and General Manager of the Port Arthur Manufacturing Complex.

PSSAP continuously updates existing protocols with industry good practices and updated API standards to maintain its status as a landmark program for the downstream natural gas and oil industry, while also expanding protocol offerings to be more inclusive of petrochemical, chemical, liquified natural gas, and gas processing facilities.

PSSAP has built on the original protocols, adding two new protocol offerings starting in 2019 for Product Storage and Transfer as well as Incident Learning. API also recently added a protocol on Safeguards in 2022, which is conducted alongside the Process Hazard Analysis (PHA) protocol. Along with these new offerings, PSSAP also created PSSAP Focused, a condensed assessment designed to meet the needs of smaller refineries, petrochemical and chemical operators. For sites where size and scale may not warrant a General Assessment, this new tailored assessment allows sites to receive critical feedback about their programs in targeted areas while still being able to take part in the program.

In 2022, API also launched an Extended Learnings Offering, through which assessors may stay on site (or return within a short time) following a General or RP 751 assessment to provide enhanced good practice sharing and additional time with the expert assessors. While good practice sharing is a pivotal part of assessments, this offering gives assessors the opportunity to provide in-depth discussions on identified observations from the assessment. Such an offering is helpful for sites with a less mature process safety management program.

After a successful first decade, API is committed to expanding the use of PSSAP assessments over the next ten years, helping industry drive toward a shared goal of zero process safety events.

“PSSAP continues to evolve to address industry’s most pressing safety challenges. In the next decade, we plan to make changes to existing PSSAP protocols as industry good practices, technology, and standards evolve as well as to add new protocols based on industry needs. Furthermore, PSSAP anticipates robust international growth by providing assessments to sites around the world that could benefit from the program’s safety systems evaluation and good practices sharing,” said Ron Chittim, API vice president of Downstream Policy.

To learn more about PSSAP and take your first step toward your assessment, please visit us here.