What do jewelers, pistol shrimp and Envorem’s new sludge treatment technology have in common?

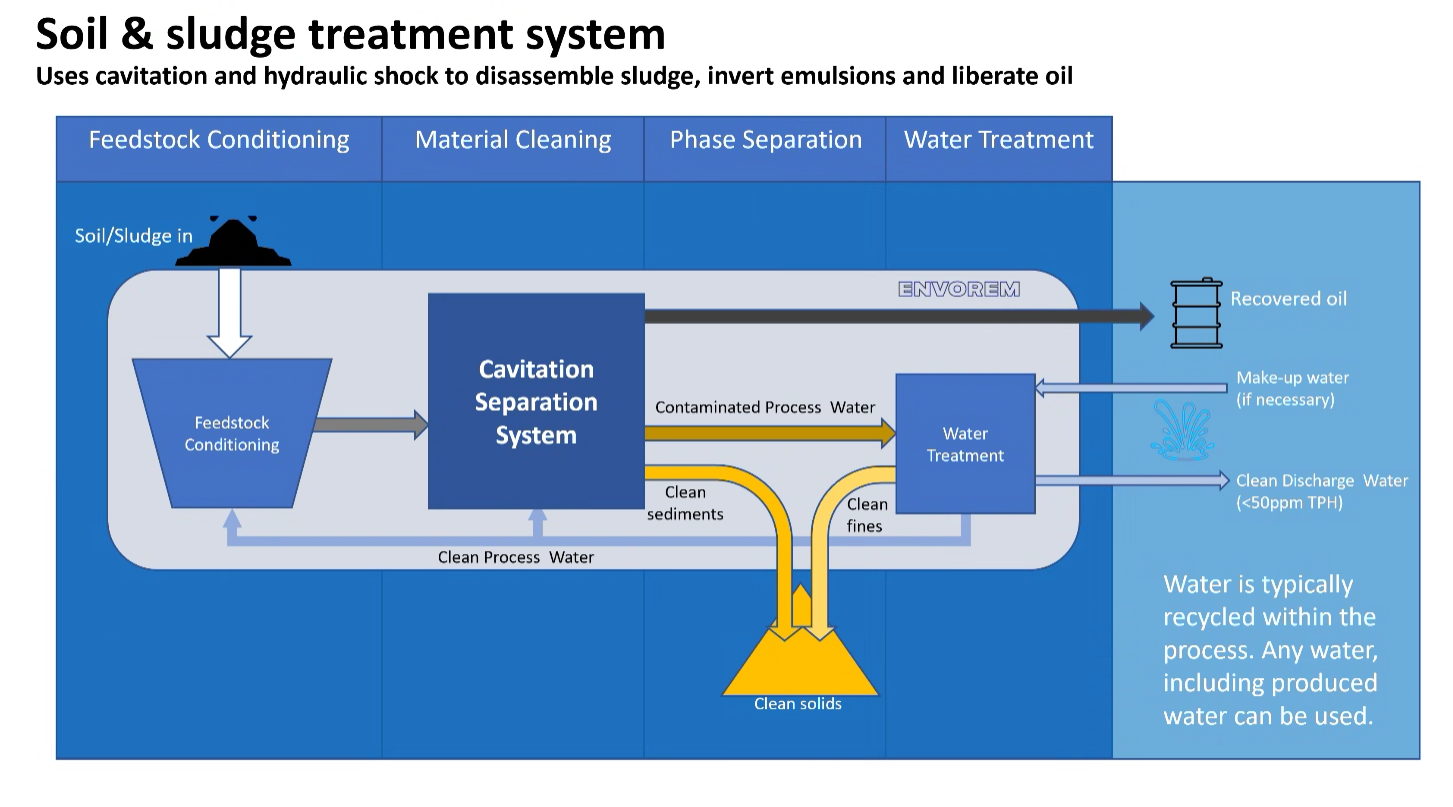

While this is a fairly odd grouping, each use a process called cavitation. Cavitation is the formation of partial vacuums in a liquid by a swiftly moving solid body or by high-intensity sound waves. Envorem CEO Mark Batt-Rawden gives a simpler definition, describing cavitation as what “happens when you move something so fast through a liquid that you vaporize the liquid within itself and it forms these kind of vacuous bubbles that implode really fast.”

Jewelers use this process to clean jewelry, pistol shrimp to defend themselves by creating shockwaves and Envorem to treat waste and recover oil left behind by producers and operators.

“What we're doing is we're harnessing the power of those bubbles to rip the contamination out of the materials that we're trying to clean off the surfaces of the particles and into the water,” Batt-Rawden told Hart Energy.

Normally, processes such as thermal desorption and incineration are used to clean left behind sludge, but they come with significant disadvantages. Desorption requires the contaminated area to first be excavated, which is quite costly, and only works up to a certain depth. Incineration is not only costly, but can also add dangerous pollutants to the air. Cavitation is both efficient and inexpensive, as it just exploits a technique copied from the natural world.

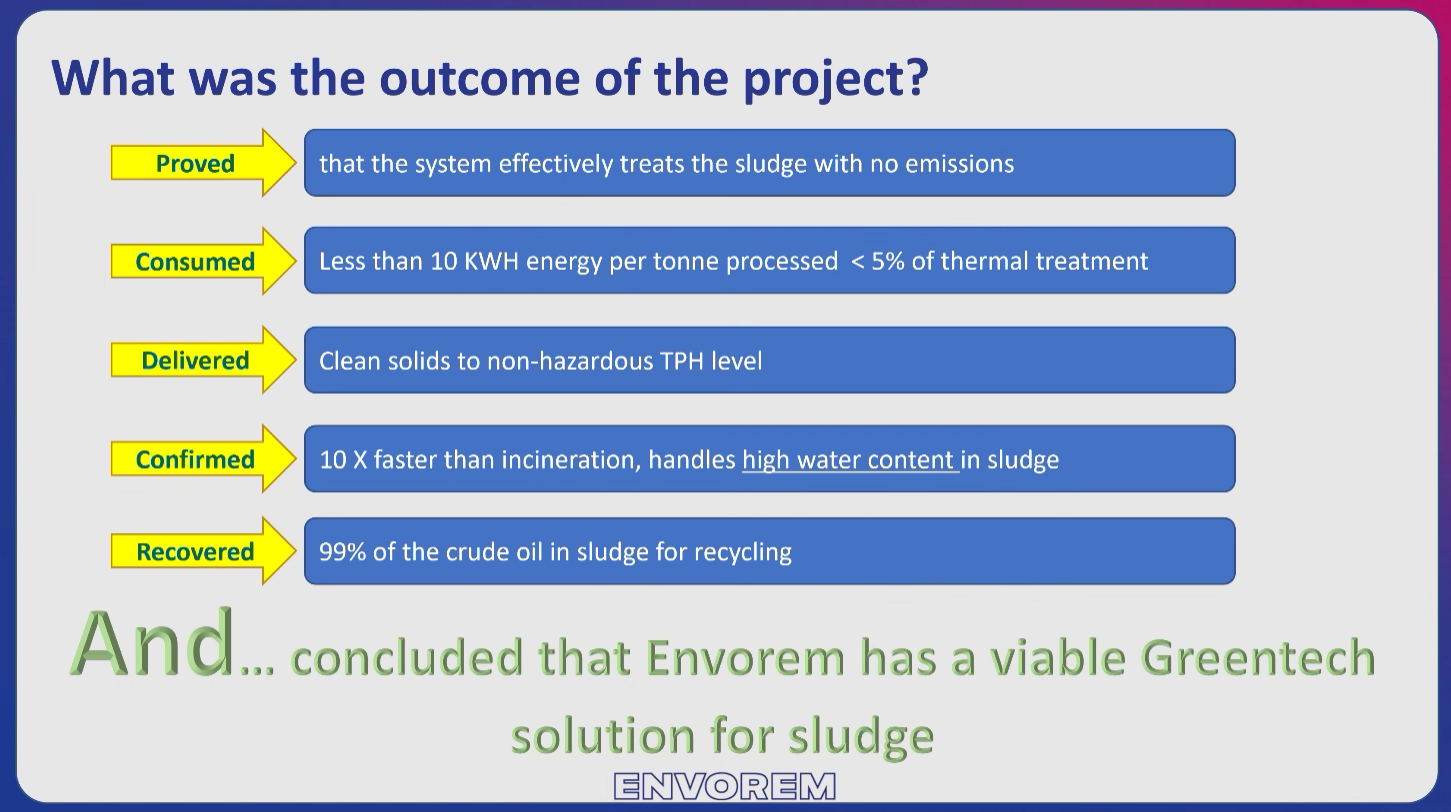

“There's some great examples out of Kuwait where they've got a massive amount of contamination they've been trying to clean up. They tried thermal desorption as a solution and found that the best they could get through a large thermal desorption machine was around five tonnes of material per hour [mt/hour],” Batt-Rawden said. “In comparison, we've already trialed our technology running at 50 tonnes an hour, so 10 times as fast. And our equipment would be about half the footprint of a thermal desorber to achieve that kind of throughput. And we'd use about 5% of the energy that a thermal system would use for our process.”

Envorem’s new process also has the ability to recover the oil it cleans, allowing it to be reused, as it doesn’t change the chemical characteristics of oil in any way. Batt-Rawden was especially keen on this application of their process because it saves money and fits into the United Nations’ sustainable development goals by recycling waste back into usable product.

“We can operate at about 40% less than the costs of thermal methods for treating these wastes, and with scale, probably less as well. But the added benefit is that our process recovers the oil for recycling, so that further offsets the cost. In some scenarios, it's even potentially that cleaning up the mess could be a profitable business as opposed to a cost,” Batt-Rawden said.

Last March, Envorem completed a highly successful pilot of its sludge removal technology for the largest oil and gas producer in Oman, the state-owned Petroleum Development Oman (PDO). The trial was a resounding success for both Envorem and Oman and received “big ticks in all the boxes,” said Batt-Rawden. Not only was the contaminated area cleaned to a better standard than expected, but more oil was recovered than was expected as well, Batt-Rawden told Hart.

Despite the successful trial in Oman and other research to back up how beneficial Envorem’s sludge solution would be to operators and producers, the industry as a whole seems reluctant to adopt this new technology.

“I think the industry is perhaps a little bit cautious because…there have been a lot of false dawns with technologies to do this job in the past,” Batt-Rawden said. “Loads and loads of companies have claimed they can do it, and every time they have tried to do it, they have failed. The industry is kind of jaundiced and they're going to want to see something really, really working before they really open up their doors.”

Currently the product is in TRL 7, with Envorem in talks with multiple classified companies to be used in their fields. Envorem has received funding from the U.K. government to speculatively build a production scale system as a demonstration of its product’s abilities. Batt-Rowden says the system will process 100 mt/hour of sludge and 25 mt/hour of solids, and looks to be finished in November of this year.

Recommended Reading

Adionics Unveils Lithium Extraction Technology For Recycled Batteries

2024-09-09 - The Paris-based company said its liquid-liquid process achieved lithium recoveries of up to 98% across a range of brine concentrations.

International, Tech Drive NOV’s 2Q Growth Amid US E&P Headwinds

2024-07-29 - Despite a U.S. drilling slowdown, slightly offset by Permian Basin activity, NOV saw overall second-quarter revenue grow by 6%, although second-half 2024 challenges remain in North America.

No Good Vibrations: Neo Oiltools’ Solution to Vibrational Drilling Problems

2024-09-10 - Vibrations cause plenty of costly issues when drilling downhole, but Neo Oiltool’s NeoTork combats these issues, enhancing efficiency and reducing costs.

AI: Herald of New Shale Age or Last-ditch Effort to Save Industry?

2024-10-03 - AI’s ability to optimize may usher oil and gas into a new age—or simply improve on past unconventional recovery methods—depending on who you talk to.

PPG’s Insulation Coating Offers Oil, Gas Asset Protection in High Heat

2024-08-21 - The PPG Pitt-Therm 909 spray-on insutlation coating can withstand high temperatures to promote safety and corrosion resistance.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.