As data become more valuable than oil, the relationship between man and machine working together becomes more harmonious. (Source: Moblize)

Machine automation has been an industry focus for more than 100 years, leading to many innovations in hardware-centric drilling optimization as companies focus on making downhole tools smarter and better. As data become more valuable than oil itself, tendencies have been to dissect and learn from data to continue optimizing drilling.

This approach, while having its merits, has not gained the engineering community’s trust and is not scalable to all basins or all business units. Why? Only a few optimization experts from the central team drive it with a very heavy engineering focus. Every basin is different, so success in one area doesn’t guarantee the same success in all. And complex variables are involved, like the heterogeneity of reservoirs and formations as well as the inconsistency of standardization of downhole tools.

Take as an example the ability to predict stuck pipe. Its prediction has been touted for 40-plus years, with every vendor or operator having some version of it. Yet can anyone claim that they can predict stuck pipe with 100% accuracy?

The key is consumerization

Houston-based Moblize took a different approach to delivering drilling efficiencies by applying analytics to enable consumerization of the oil and gas enterprise and fully unlock human intelligence. Consumerization happened in three waves. In the first wave consumers (engineers) said, “I’ll work with whatever system you give me.” In the second wave they said, “I’ll bring a better system; just support it.” In the third wave they’re saying, “I expect a system that enables a better way of working. Deliver it.”

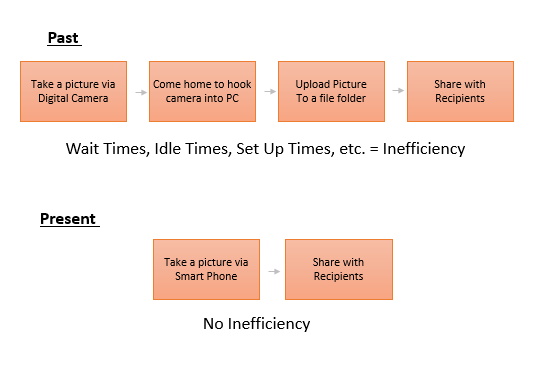

So the baseline expectation has shifted, led by an increasing number of experiences in engineers’ personal lives becoming easier and better. Frequently, mobile apps are becoming the most important client as users look for the convenience of “any time, any place” access, and apps take advantage of the many converged features on a smartphone (e.g., geolocation, multimodal communications, camera, applications, etc.).

Growth platform: the natural evolution

This approach guided the development of the ProMPT growth platform that focuses on improving the daily lives of oil and gas engineers. To guarantee success, a growth platform must:

- Eventually support a diverse set of participants and offer opportunities for creating value in many distinct areas;

- Scale up by accommodating a large user base without eventually adding unacceptable cost/issues;

- Generate increased returns as participation grows;

- Evolve continuously in functionality over time, providing incentives for participants to engage regularly and share learnings;

- Provide development leverage (investment required to build additional functionalities) and interaction leverage (effort and cost for diverse set of participants to facilitate interaction), and;

- Define practices to eventually guide the activities of a large number of participants at the enterprises.

An example of a successful growth platform is the smartphone. The result was the smartphone collapsing all previous inefficiencies in daily workflows and making users more productive to focus on things and decisions that matter.

A growth platform for drilling engineers

ProMPT is a cloud-based growth platform that includes ProACT for drilling engineers; ProFRAC for completion engineers; and ProWISE, a private artificial intelligence knowledge platform for the entire oil and gas enterprise.

ProACT maps the entire decision universe of drilling engineers in four broad categories: planning, daily operations, post-well analysis and reporting. It’s become an all-in-one analytics platform by giving drilling engineers a single source of truth in those four areas.

The typical drilling engineer is overloaded with work due to highly inefficient daily workflows. Because of time constraints decisions are often made on intuition instead of facts, which can lead to overlooking opportunities and underestimating risks. ProACT allows drilling engineers to do more with less by collapsing inefficiencies in daily workflows so they that can spend time where truly needed—engineering.

It applies machine intelligence on incoming raw data from a variety of data lakes in real time to provide actionable facts and support big judgment from Big Data. This was a paradigm shift in oil and gas since traditional wisdom states that getting a return on investment is only possible by optimizing drilling tools. Moblize helped its clients rip up the old scripts and write new ones to fully unlock human intelligence and creativity in ways not possible before.

Case study

A common decision dilemma is determining how to select the best rig contractor and rig for the job in real time. Prior to ProACT, this type of decision would require at least two days of analysis, which could result in lost opportunity. From a workflow perspective, client engineers would request rig metrics from multiple contractors and then compile drilling metrics from instrumentation providers. Then they would have to find time to perform analysis. This would require downloading and later uploading all metrics into spreadsheets, running calculations and comparing results.

With data provided by RT Analytics from ProACT, engineers can instantly be presented with actionable insights like drilling and tripping connection times, parameters and rig utilization by driller, and tripping rates between many rigs for multiple hole sections to determine the best performer. Further, granular analytics showcase metrics for the best well drilled in an area against active wells, revealing more contextual information around whether a driller is using the current rig to maximum ability, such as optimal block speed while tripping. In this case the data showed that the active rig was considerably slower than the best performer, suggesting that engineers analyze tripping rates.

The machine-guided facts showed the blocks were moving much slower at the beginning and end of each stand tripping in or out of the hole. Upon closer investigation, engineers found the driller was easing into and out of each stand on the joystick that controls the rig, considerably reducing the overall efficiency. All this cannot be easily interpreted unless multiple vendor reports and applications are touched, manipulated and prepared as insights—a true engineering nightmare.

The power of providing actionable insights guided by real-time machine intelligence in this example of a “data-to-decision” workflow collapsed traditional inefficiencies by 80%, as engineers could instantly share factbased insights. This resulted in a decision to change driller behaviors allowing trip rates of eight to 10 stands per hour faster than was previously seen. Savings totaled almost six hours on each lateral trip, and the team was able to drill the well from spud to total depth faster with the old rig instead acquiring a new rig that would have cost the company an additional $120,000 if such insights were not available.

Recommended Reading

Patterson-UTI Updates Drilling Rig Status

2024-09-10 - Patterson-UTI’s monthly announcements represent the company’s average number of revenue-earning drilling rigs in the U.S.

Kolibri Global Drills First Three SCOOP Wells in Tishomingo Field

2024-09-18 - Kolibri Global Energy reported drilling the three wells in an average 14 days, beating its estimated 20-day drilling schedule.

E&P Highlights: Sept. 23, 2024

2024-09-23 - Here's a roundup of the latest E&P headlines, including Turkey receiving its first floating LNG platform and a partnership between SLB and Aramco.

US Drillers Add Oil, Gas Rigs for First Time in Four Weeks

2024-10-11 - The oil and gas rig count rose by one to 586 in the week to Oct. 11. Baker Hughes said the total count was still down 36 rigs or 6% from this time last year.

Seadrill to Adopt Oil States’ Offshore MPD Technology

2024-09-17 - As part of their collaboration, Seadrill will be adopting Oil States International’s managed pressure drilling integrated riser joints in its offshore drilling operations.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.