Presented by:

Editor's note: This "Tech Trends" section appears in the new E&P newsletter. This weekly section highlights the latest upstream technologies and services for the oil and gas industry. The copy herein is compiled from press releases and product announcements from service companies and does not reflect the opinions of Hart Energy. Submit your company’s updates related to new technology products and services to Ariana Hurtado at ahurtado@hartenergy.com.Subscribe to the E&P newsletter here.

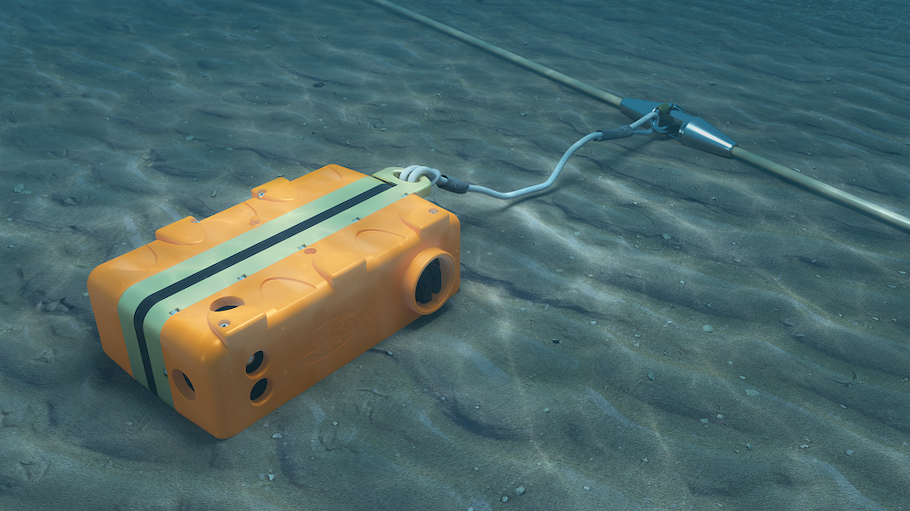

Sercel and BGP partner on new seabed node for shallow water

Sercel has released its GPR300, a new nodal seismic acquisition tool specially designed for deployment in shallow waters down to depths of 300 m. Developed in partnership with BGP, the new solution expands Sercel’s existing GPR NT range, which includes GPR1500 for high-end deepwater subsurface imaging. Compact and lightweight, GPR300 features Sercel’s QuietSeis broadband digital sensor technology for ultra-quiet performance and unmatched digital fidelity. Its ability to record high-fidelity, low-frequency signal also makes it the ideal choice for high-end seismic imaging with full-waveform inversion. In addition, its omni-tilt sensor package corrects for node inclination on the seabed, ensuring the most accurate 3C recording. GPR300 benefits from BGP’s significant know-how in seismic acquisition and Sercel’s technical expertise in design and manufacture of marine seismic equipment. BGP also provided valuable input from the field, ensuring that this new-generation node is precisely tailored to meet the very latest seismic industry requirements.

Gardner Denver valve increases performance hours during HP fracking

Gardner Denver (GD) High Pressure Solutions division has proven in field trials that its new V3 valve significantly increases performance hours in high-pressure hydraulic fracturing operations. GD Redline valves and seats are designed for maximum performance and reliability, with the full-open, bonded design providing optimal flow efficiency and maximum sealing. The V3 valve has undergone a complete redesign to improve metallurgy and heat treatment resulting in enhanced wear resistance and strength. During field trials in the Eagle Ford, Permian and Marcellus shale plays, increased performance of up to 46% over the leading competitor was observed. In the Permian Basin, performance of the V2 and V3 could be compared, with an increase in performance of 81% witnessed. The V3 valve is suitable for use with any standard fluid end utilizing P-4 and P-5 valve configuration.

Kongsberg Digital cloud simulation training technology offered anytime, anywhere

Kongsberg Digital (KDI) has released its K-Sim ECDIS, the latest in a line of cloud simulation solutions the company has produced for the maritime training sector. K-Sim ECDIS has been designed to provide generic ECDIS (electronic chart display and information system) training in compliance with the requirements laid out in the IMO/STCW Model Course 1.27. Accessible as an online training tool via the company’s digital platform K-Sim Connect, it enables schools and training centers to efficiently provide their students with high-quality ECDIS training anytime and anywhere without the need for major hardware investment. Based upon several key elements from Kongsberg Maritime’s real-life K-Nav ECDIS, K-Sim ECDIS accommodates all the relevant and necessary functionality for instructing students in the key operations of electronic charts, route planning and navigation. The system will be delivered as a complete training package and include ready-made simulation exercises. Seamless integration with school-based simulators such as K-Sim Navigation and K-Sim Radar will allow for highly effective blended learning, combining cloud-based and classroom instruction with the benefits of full flexibility and availability for the instructors and students. K-Sim ECDIS’ route planning and validation application, K-Sim Planning Station, will be available as a standalone system in June this year, followed by a rollout of the complete K-Sim ECDIS solution by fall 2021.

Logan Industries delivers custom-built skinny coiled tubing lift frame in Trinidad

Logan Industries has successfully delivered a custom-built skinny coiled tubing lift frame (CTLF) for a customer in Trinidad. The job scope involved providing a safe and consistent platform to stack up/rig up wellbore pressure control equipment above the drill floor of an offshore drilling vessel to allow the service provider to place an injector unit on the platform (lift frame IH table). The CTLF needed to accommodate several overhead lifting hoists and a davit crane with the on-site flexibility in movement of the table and crane with a wireless remote control.

DLM’s new device measures tension and holds back 500 kg of subsea cable line tension

Dynamic Load Monitoring (U.K.) Ltd. (DLM) has expanded its range of line tension measurement technology with a new device for measuring tension and creating holdback force on a single piece of subsea cable. The product, which combines the established Saddleback (SB) product from DLM’s catalog with an additional Hold Back Tension (HBT) element, is being primarily used by the vessel NKT Victoria, with further devices in the pipeline for a number of customers. When consulted about a solution for measuring line tension and creating a holdback force for a cable lay project, DLM devised the SB-HBT. The SB-HBT, which weighs 450 kg, works by creating additional line tension on the subsea cable running through it, specifically for bundled cable lays. An SB can measure line tension from 0 kg to 5,000 kg and is suited for more delicate cable, including telecommunication cables or large cable where a running line monitor is unsuitable. Moreover, a twin pair of Dunlop 18 x 7 SMO LCE tyres are connected to a hydraulic cylinder to clamp the two wheels together, and a disc braking system is used to control the rotational speed of the wheels on the SB-HBT. The device can create 750 kg of clamping force between the wheels and hold back 500 kg of line tension. On the top wheel there is an encoder to measure speed and distance.

Bottom: The tyres are connected to a hydraulic cylinder to clamp the wheels together.

(Source: Dynamic Load Monitoring (U.K.) Ltd.)

William Hackett hoists increase operational safety and performance levels provided by chain blocks

William Hackett, a manufacturer and supplier of offshore lifting hoists and chains, announced a major step forward for onshore operators with the release of its WH C4 QP, which incorporates the company’s quad pawl (QP) mechanism. The company boasts it is "the safest and most efficient chain hoist in the world." Safe and continual performance of lifting equipment crucially depends on minimizing risk through improved resilience to failure. Lift operations are often fast-moving, challenging and hazardous environments. Improvements in efficiency, ease of use and safety can yield large returns for operators across any industry, from construction, engineering and shipping through to energy and transport. The QP works by allowing all four pawls to engage with the ratchet gear in an offset configuration that allows finer adjustment and tensioning capability, while maintaining pawl and ratchet gear engagement. The pawl springs are enclosed in the product’s brake chamber to minimize contamination. The pawl design ensures that in the unlikely event of both pawl springs failing, the quad pawls maintain full function with the ratchet gear, making the hoist operation much safer to use. The QP mechanism synchronizes to minimize the time and distance traveled to the next point of engagement further improving hoist times and providing smooth lift operations.

Recommended Reading

Supreme Court Takes Up Clean Air Act Venue Fight

2024-10-21 - The high court’s justices will hear arguments if the EPA’s air pollution rules should be challenged in D.C. or in regional courts.

New EPA Regulations Could Hinder Gas Plant Construction

2024-10-14 - The rules are designed to accelerate the retirement of coal plants, but they raise costs for new natural gas facilities.

EQT’s Rice: ‘Wake Up’ to Anti-Energy Movement

2024-11-08 - In the face of growing opposition to fossil fuels and energy infrastructure, EQT CEO Toby Rice pulled out a rallying cry at Hart Energy’s DUG Appalachia conference: “Wake up!”

Texas is Sued Over Anti-ESG Law

2024-08-29 - A nonprofit organization is suing Texas over a 2021 law it says violates members’ free speech rights by banning Texas from investing in or contracting with businesses that, in the state's view, "boycott" the oil and gas industry.

Venture Global Taking Adequate Steps in Calcasieu Pass Construction, FERC Says

2024-10-01 - The Calcasieu Pass LNG plant’s foundational customers have turned to legal auction due to the plant’s long commissioning time.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.