Presented by:

This article appears in the E&P newsletter. Subscribe to the E&P newsletter here.

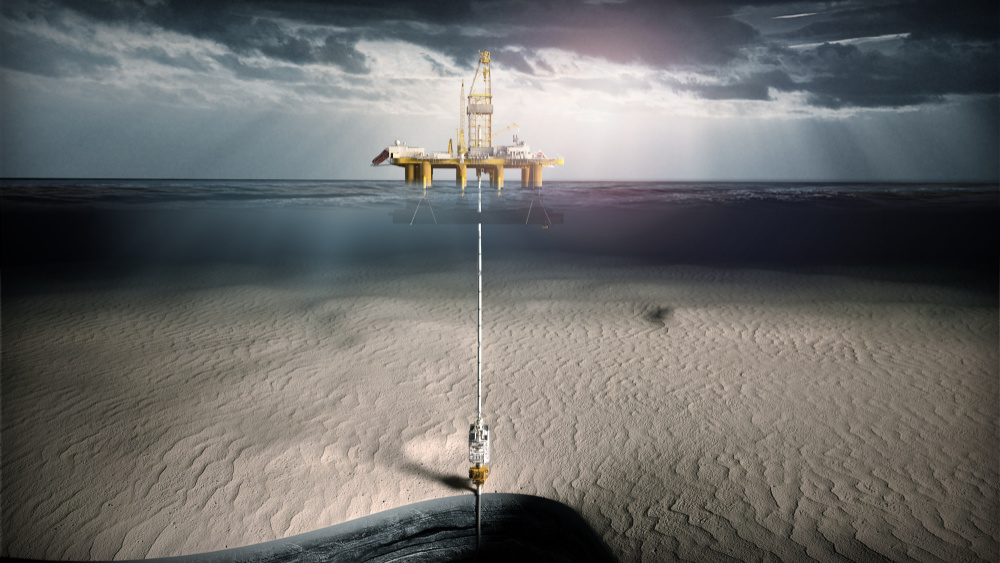

Subsea exploration well systems are subjected to complex loading due to vessel motion and hydrodynamic forces on the riser. Extreme loading and the fatigue design under operational loading are heavily dependent on the soil support along the uppermost section of the conductor casing.

Since 2017, 4Subsea, a provider of digital technology and services to the energy and maritime sector, has monitored BOPs and riser responses across several exploration drilling campaigns in the North Sea and the Barents Sea for Lundin Norway. The purpose is to track the performance of the wells over time, based on integrity parameters such as well stiffness, BOP resonance frequency and BOP motion rotational depth.

In one exploration well, the operator experienced escalating instability while drilling caused by washout, resulting from vessel and wave-induced motions on the BOP and by challenging soil conditions. An ROV was used to visually observe the movements of the BOP.

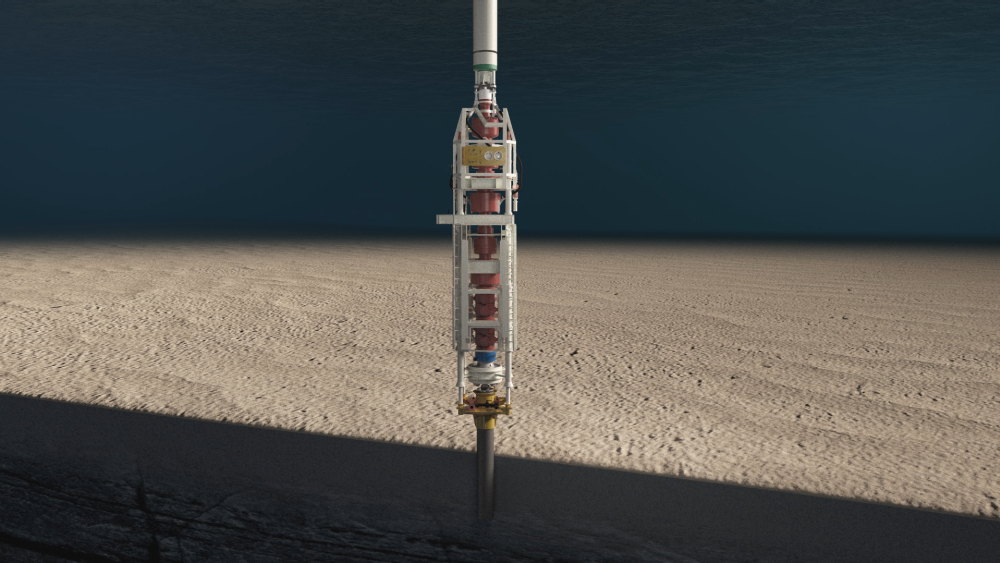

4Subsea’s SWIM (Subsea Wellhead Integrity Monitoring) system, employs retrofittable subsea sensors to monitor and measure the wellhead system’s stability, load, fatigue and structural integrity during drilling operations, was then employed to create a digital twin of the well. In tandem with advanced data analytics, the virtual model was used to update conditions, evaluate the consequences and verify wellhead integrity throughout the remainder of the operation.

Access to real-time, critical data empowered engineers to collaboratively make operational decisions and avoid abortion of an ongoing drilling operation, resulting in significant cost and uptime savings. “The use of 4Subsea’s SWIM has enabled us to avoid escalating conductor instability and continue the drilling operation on one of our exploration wells,” said Randi Næss, leading drilling engineer at Lundin Norway.

In this context, a digital twin is a model representation of the well system, riser system and boundary conditions using data from autonomous sensors. The use of state-of-the-art sensors and wireless subsea data-transfer enabled Lundin Norway to feed measurements directly into DataReservoir.io. DataReservoir.io is implemented in Microsoft Azure (PaaS) to handle large amounts of time-series data and distribute it in a secure and efficient matter. Data and insight can be distributed through REST API, advanced Python API, or through dashboards on the digital platform 4insight. Engineers typically use Python API to run specialized analyses.

A machine learning based alarm, trained on historical data to strengthen the model, evaluated the consequences of change in the well’s supporting structure, with respect to structural wellhead and soil utilization. Well specific operating envelopes and wellhead fatigue development were adjusted according to changes in the stiffness of the well support (Figure 2).

Successful identification of an escalating conductor instability situation resulted in targeted mitigative action to fill the washed-out well slot, allowing the drilling operation to continue. This reduced cost and risk by ensuring safe utilization of the mobile drilling unit.

Digital dexterity

Since it was first tested in 2010, SWIM has identified wellhead integrity issues, such as shallow gas and water, conductor stability issues related to washout or fatigue challenges, on nearly a third (30%) of exploration and satellite wells monitored in depths less than 150 m. It has an extended battery life from one to five years and can operate in water depths down to 3,000 m.

The technology enables operators to reuse critical wells and maximize the lifetime of wellheads by scheduling drilling operations based on well criticality, historically accumulated load on wellheads and predictive models. The predictive models estimate the expected load on the wellheads from future planned drilling and intervention operations.

4Subsea also recently launched the SWIM Live app, which provides live data streaming from sensors installed on the BOP and lower flex joint through integration with the BOP MUX umbilical. This allows real-time updates and the ability to optimize operations with instant insight.

About the author: Vegard Martinsen serves as vice president of drilling monitoring for 4Subsea. The company was established in 2007 and provides technology and services that help operators optimize energy production from subsea oil and gas fields as well as offshore wind farms.

Recommended Reading

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.