The ESTMZ system concept originated in the mid-2000s to increase the performance envelope and drive further operational simplicity of the already field-proven HAL STMZ system. This new system specifically addressed the increasing demands of the Gulf of Mexico (GoM) Lower Tertiary. After considerable concept development, planning and research, Halliburton moved forward with system design and manufacture leading up to several system integration tests and full-scale field trials.

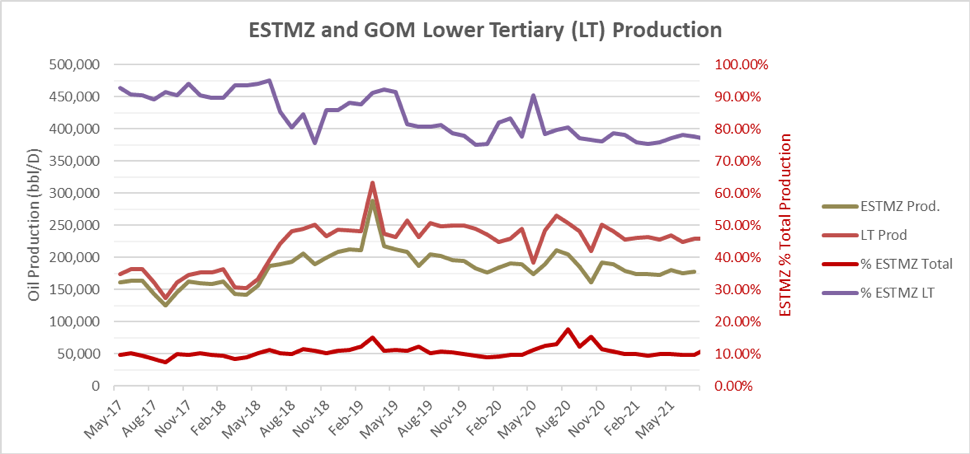

Then, in the summer of 2012, Halliburton installed the first commercial ESTMZ system completion in the Lower Tertiary. Now, some 10 years later, more than 10% of the total production output in the GoM is being produced through the completion systems that Halliburton designed, manufactured, and installed (Figure 1).

A total of 36 Xtreme Single-Trip Multizone (XSTMZ) and ESTMZ completions—made up of openhole ESTMZ, cased hole XSTMZ and openhole XSTMZ configurations—have been installed in the Lower Tertiary, amounting to 133 individual zones. To date, operators have injected over 70 million lb of proppant into the Lower Tertiary to frac and stimulate production through these systems. Treatment volumes and rates are designed specifically for each well, with pump rates varying from 15 to 45 bpm. The record for the most proppant placed in a single zone to date is 954,000 lb, which was limited by the formation. During a separate operation, an incredible 3.063 million lb of proppant was pumped using a single service tool in one completion. Wellbore trajectories are typically vertical or near-vertical, with the greatest deviation into which these systems have been installed being just above 50 degrees. System lengths vary from about 450 to 3,200 ft, with individual zone lengths ranging from 42 to 240 ft. Installed measured depths (MD) of these completions range from about 26,000 to more than 31,000 ft.

As these fields mature, formation pressure depletion in some pay intervals has challenged conventional completion methods. Fluid losses to the depleted intervals, while maintaining well control of the higher-pressure intervals, must be managed correctly to prevent wellbore collapse. It was soon understood that depletion would present a distinct and unique challenge. Once fluid losses after perforating could no longer be managed effectively, the need for a different approach became evident. This need was addressed by separating the deeper lower-pressure depleted zones from the higher-pressure pay zones above and completing the well with a stacked version of the ESTMZ system. Stacking the systems allowed for better control of the well and fluid loss issues after perforating while maintaining the inherent benefits of single-trip systems.

As the layered reservoirs continued to deplete at varying rates, it was realized that a more robust solution would be necessary. In addition to managing fluid losses, the differential ratings of the packers and equipment installed across depleted and virgin pressured zones required consideration. The original pressure-rated equipment limited the maximum surface treating pressure to prevent over pressuring of the downhole tool system. Such limitations in treating pressure can adversely affect the treatment regimen and thus the resulting production. Perhaps a lesser-known consideration is the reduction in the allowable amount of pressure that can be applied during the reverse out stage of the completion. In this scenario, a significantly constrained maximum reverse out pressure can hinder operations flexibility and reduce the probability of success when reversing out in a worst-case scenario, such as a hard sandout with a work string column full of sand. Completion depths and hydrostatic pressures inherent to the Lower Tertiary further exacerbates these challenges. To better address these issues, Halliburton developed the XSTMZ system, bolstering the system rating to 15,000 psi at 300 F.

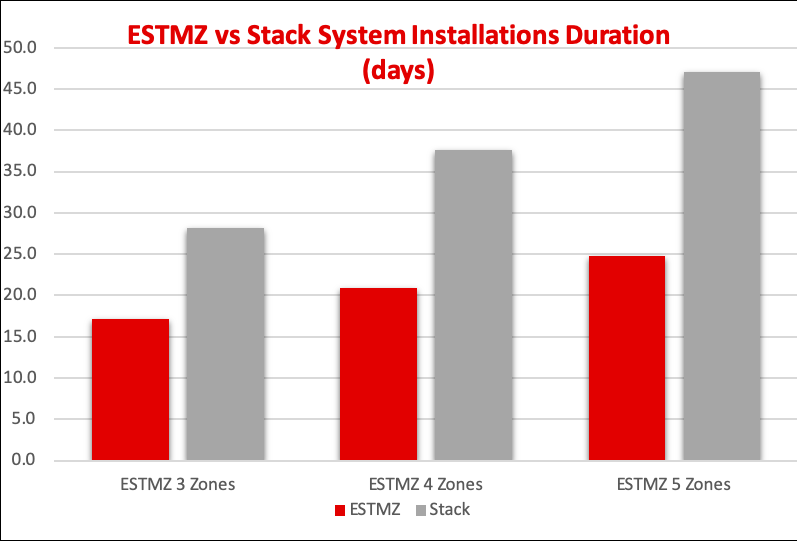

Perhaps not fully appreciated during initial system development, the efficiencies achieved with the XSTMZ and ESTMZ completions also allow for a significant reduction in the operators’ carbon footprint throughout the entire operation by saving operational time offshore and optimizing utilization of frac and supply vessels (Figure 2), thus offering a notable systems advantage.

Specifically designed to meet the completion requirements of wells in the Lower Tertiary, the XSTMZ and ESTMZ systems are making a resounding impact on the way that completions are performed in the GoM and the volume of oil that is produced. By working closely with our clients and listening to the industry’s needs, Halliburton continues to deliver products, expertise and service quality to meet the critical challenges observed in the GoM Lower Tertiary and beyond.

Recommended Reading

Utica’s Encino Boasts Four Pillars to Claim Top Appalachian Oil Producer

2024-11-08 - Encino’s aggressive expansion in the Utica shale has not only reshaped its business, but also set new benchmarks for operational excellence in the sector.

Houston Natural Resources to Rebrand to Cunningham Natural Resources

2024-11-08 - Now rebranded as Cunningham Natural Resources Corp., the company will continue its focus on traditional oil and gas opportunities and energy transition materials.

US Oil, Gas Rig Count Holds Steady for Record Third Week

2024-11-08 - The oil and gas rig count was steady at 585 in the week to Nov. 8, Baker Hughes said on Nov. 8. Baker Hughes said that puts the total rig count down 31 rigs, or 5% below this time last year.

SM, Crescent Testing New Benches in Oily, Stacked Uinta Basin

2024-11-05 - The operators are landing laterals in zones in the estimated 17 stacked benches in addition to the traditional Uteland Butte.

Comments

Add new comment

This conversation is moderated according to Hart Energy community rules. Please read the rules before joining the discussion. If you’re experiencing any technical problems, please contact our customer care team.