Shale Technology Showcase

2019

The latest products and technologies for shale

In this special section, E&P Magazine highlights some of the latest products and technologies for shale development and looks at how they will benefit companies in their ongoing search for improved production and more effective operating techniques.

Editor’s note: The copy herein is contributed from service companies and does not reflect the opinions of Hart Energy.

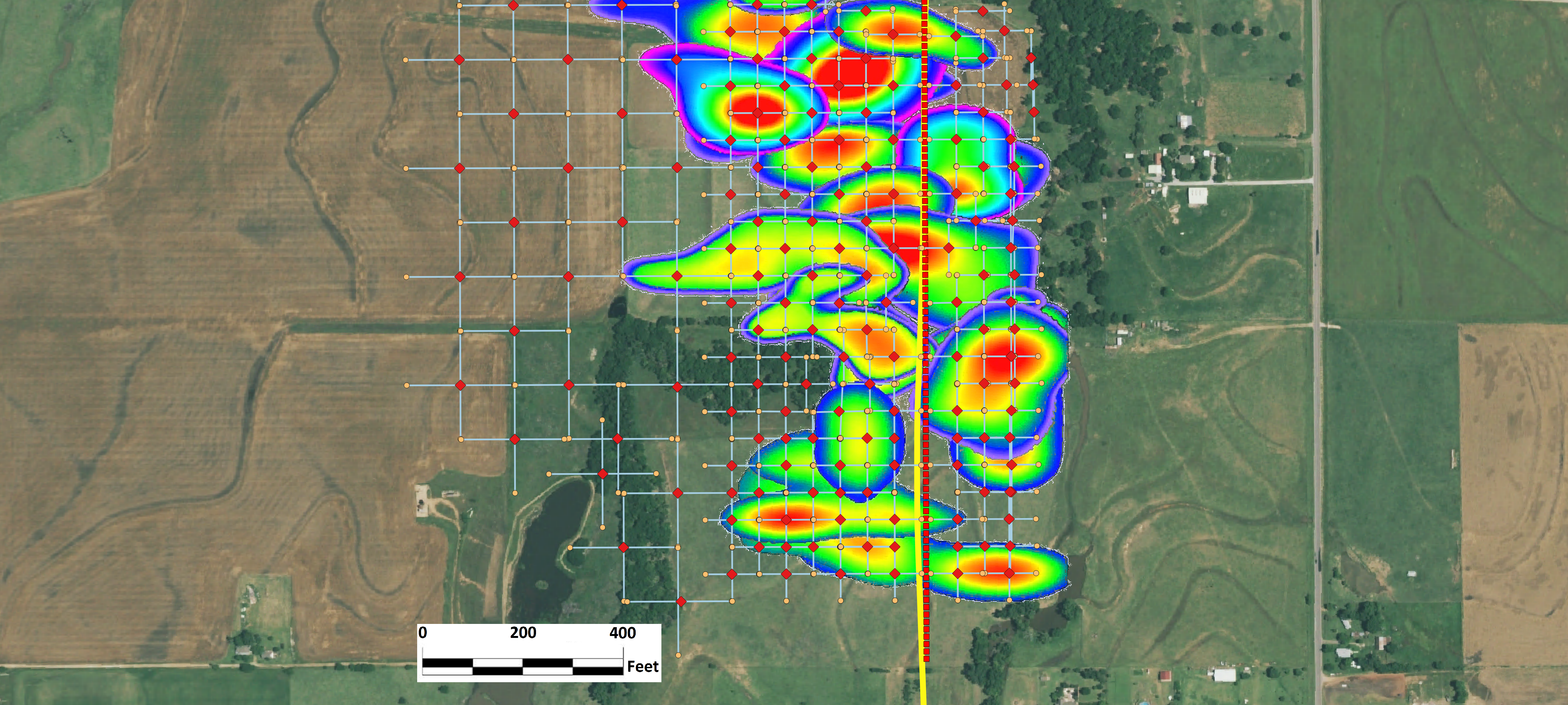

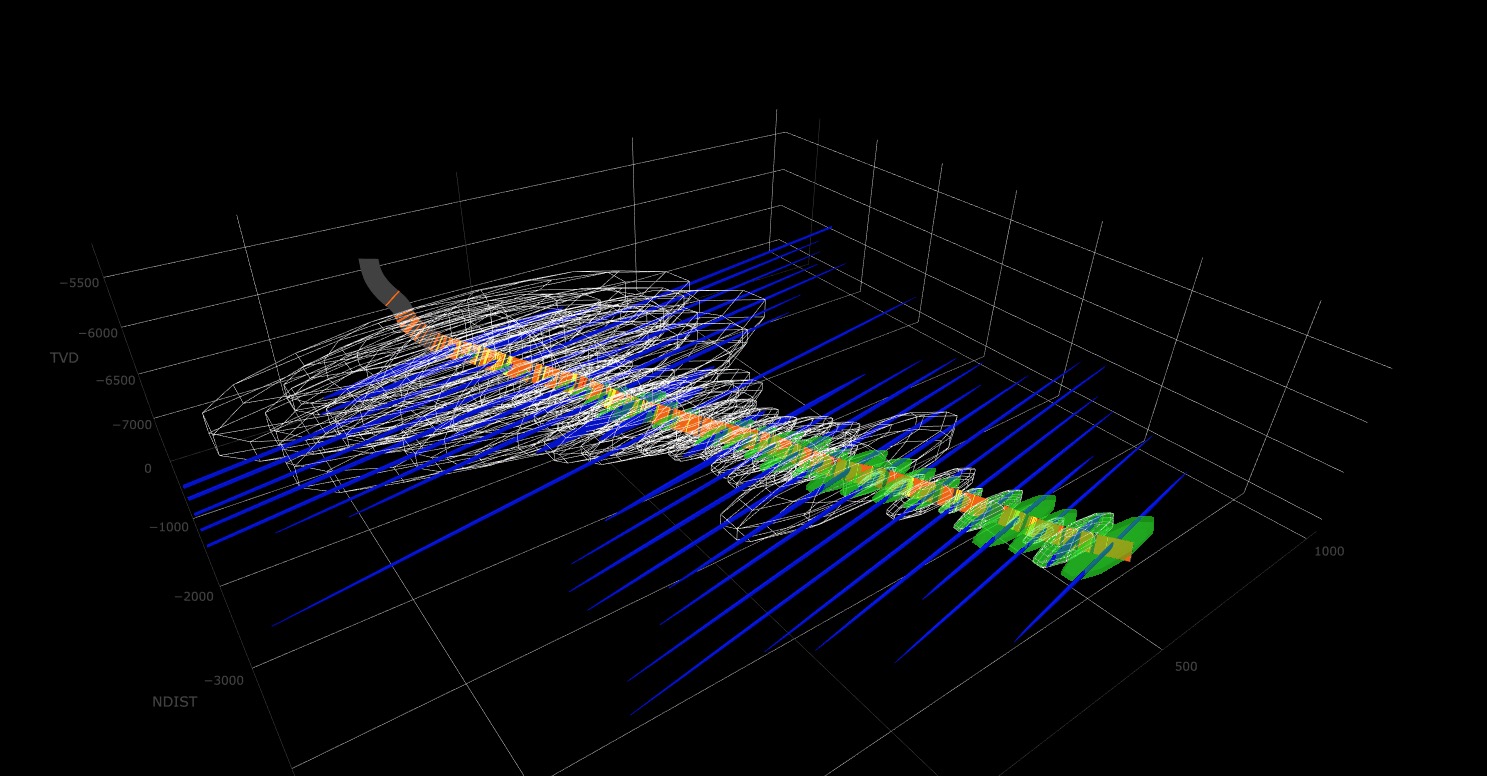

Exploration

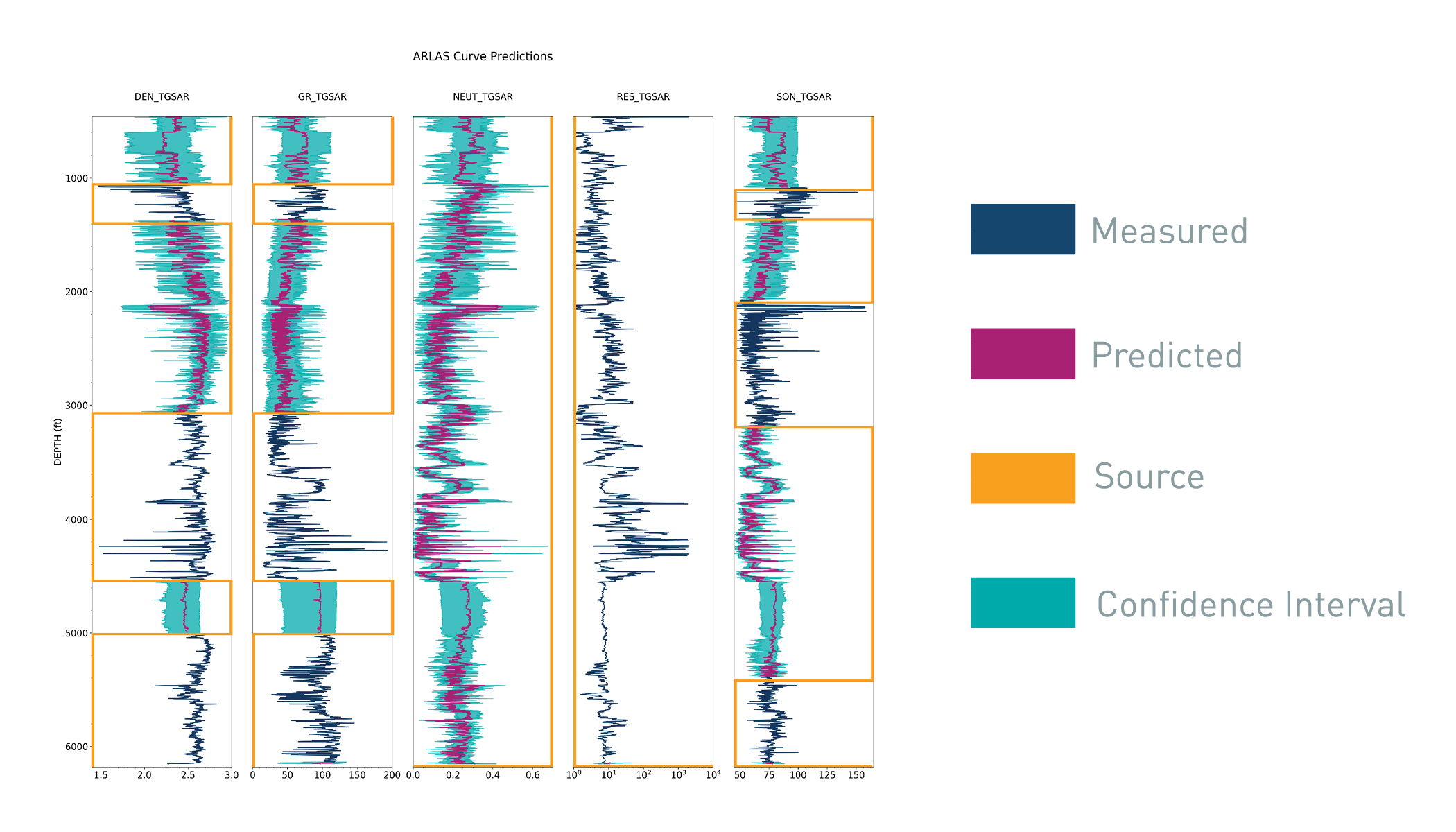

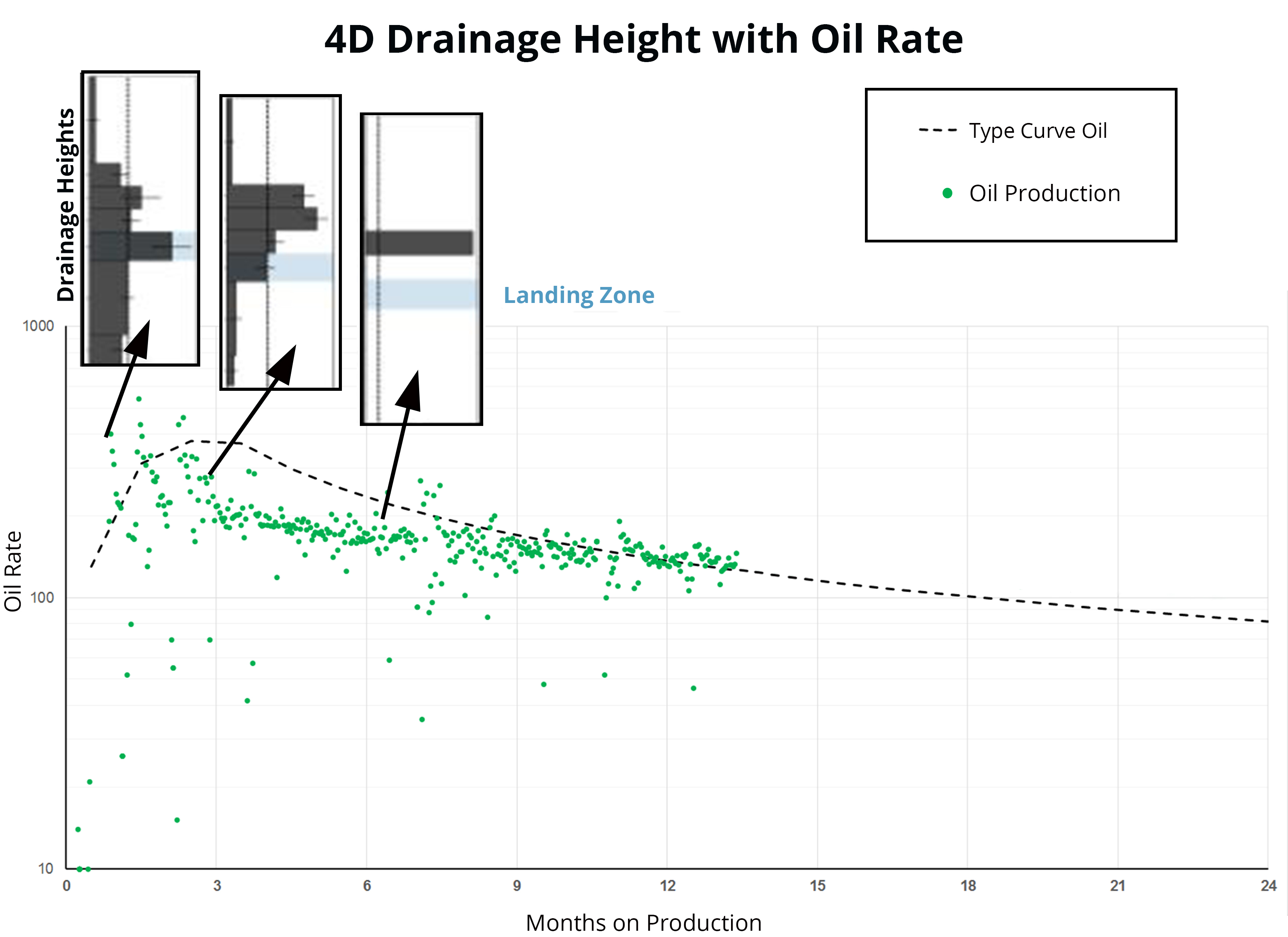

Subsurface sensing tools, seismic processing/interpretation, reservoir characterization, rock physics, geomechanics and logging tools—the exploration technologies that upstream oil and gas operators seek out and use are abundant. The goal is the adoption of these tools will result in more efficient shale development and greater recovery.

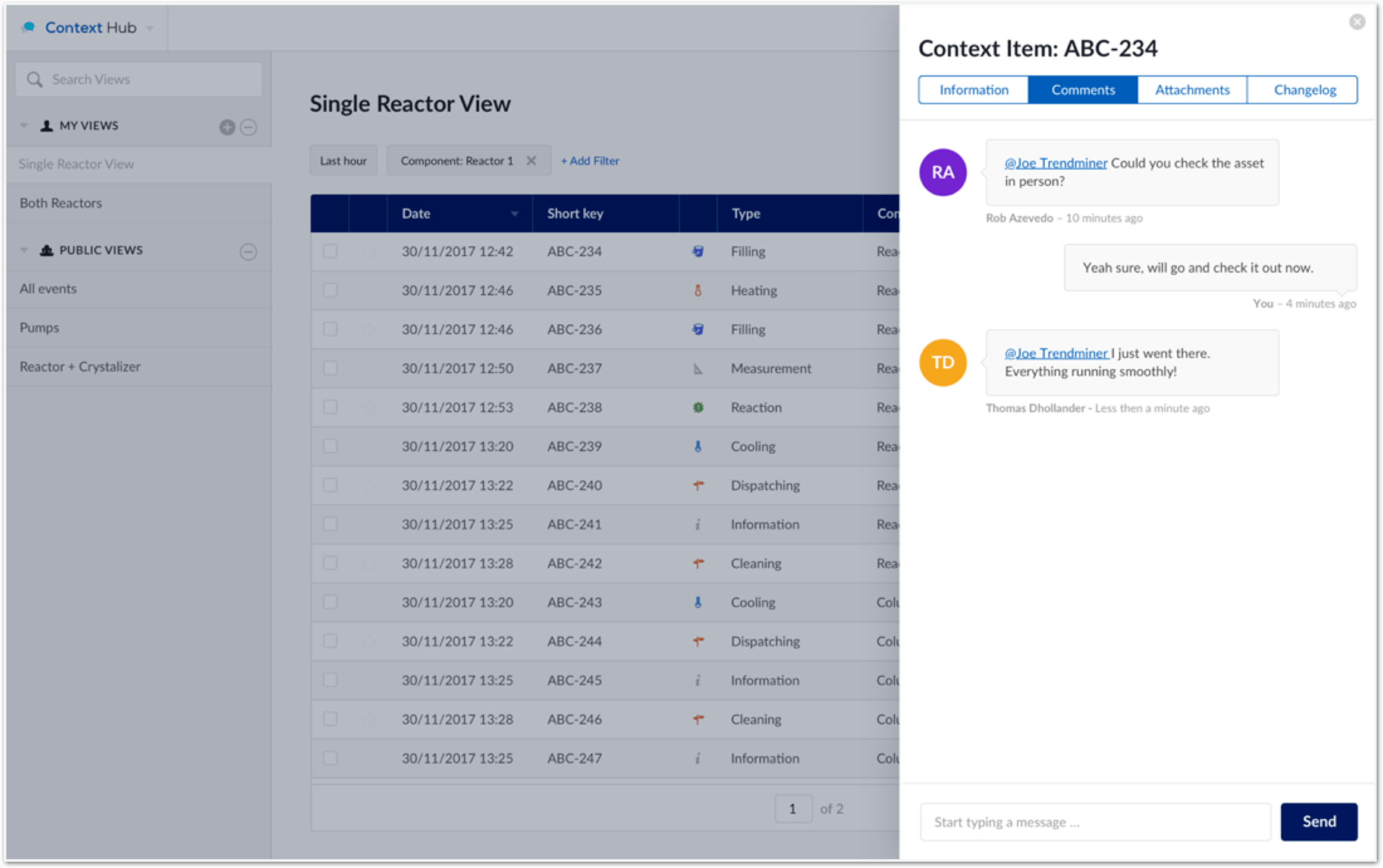

"In this tail end of the recent downturn, operators who managed to develop workflows using data in ways that weren’t thought of before are emerging as the leaders," Carl Neuhaus, vice president of Well Data Products at TGS, told E&P. "Analytics, [which is] fueled by large amounts of high-quality data that are democratized across disciplines so all stakeholders are involved in ground-truthing algorithms, is proving to increase the NPV [net present value] of shale assets."

The importance of predictive maintenance is increasing in oil and gas operations, according to a recent news release by GlobalData. "The adoption of predictive maintenance technologies is helping companies cut back on operational expenditure by optimizing maintenance scheduling and driving productivity," the report stated.

The following is a sampling of new exploration technologies and services that were developed to improve efficiencies.

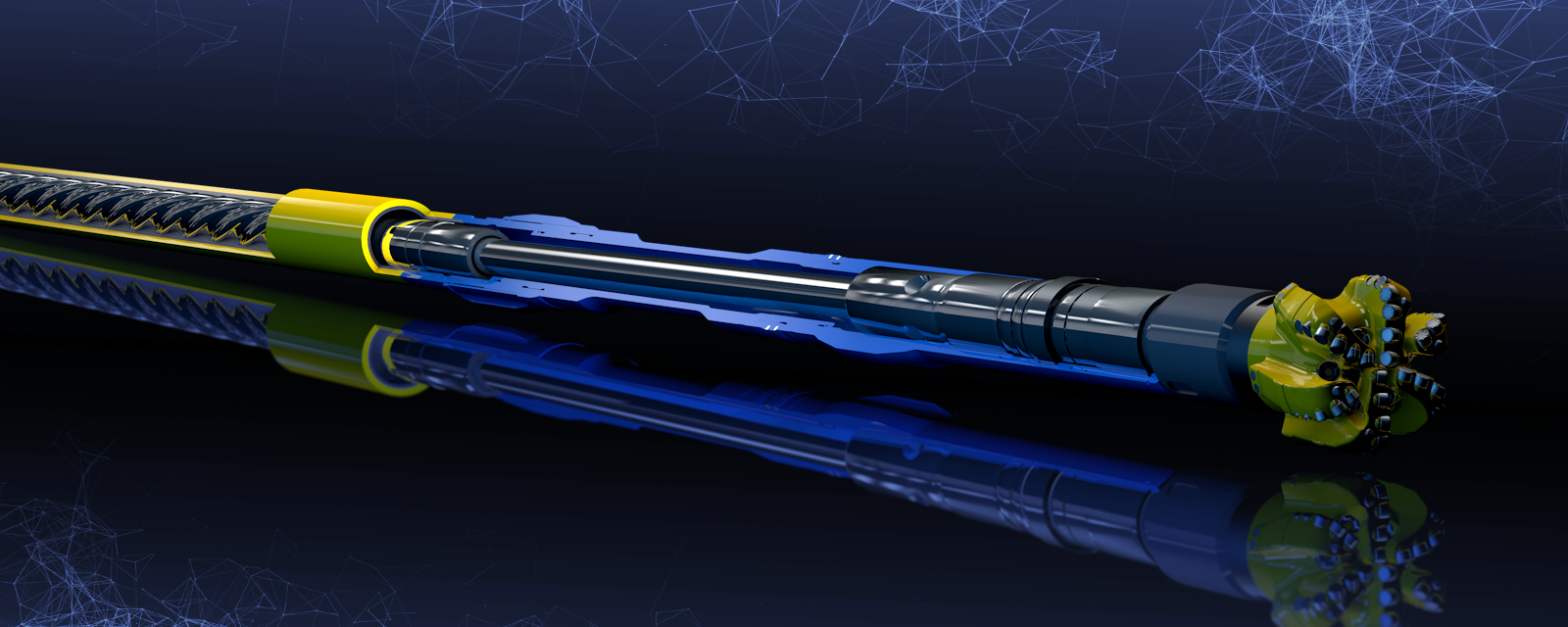

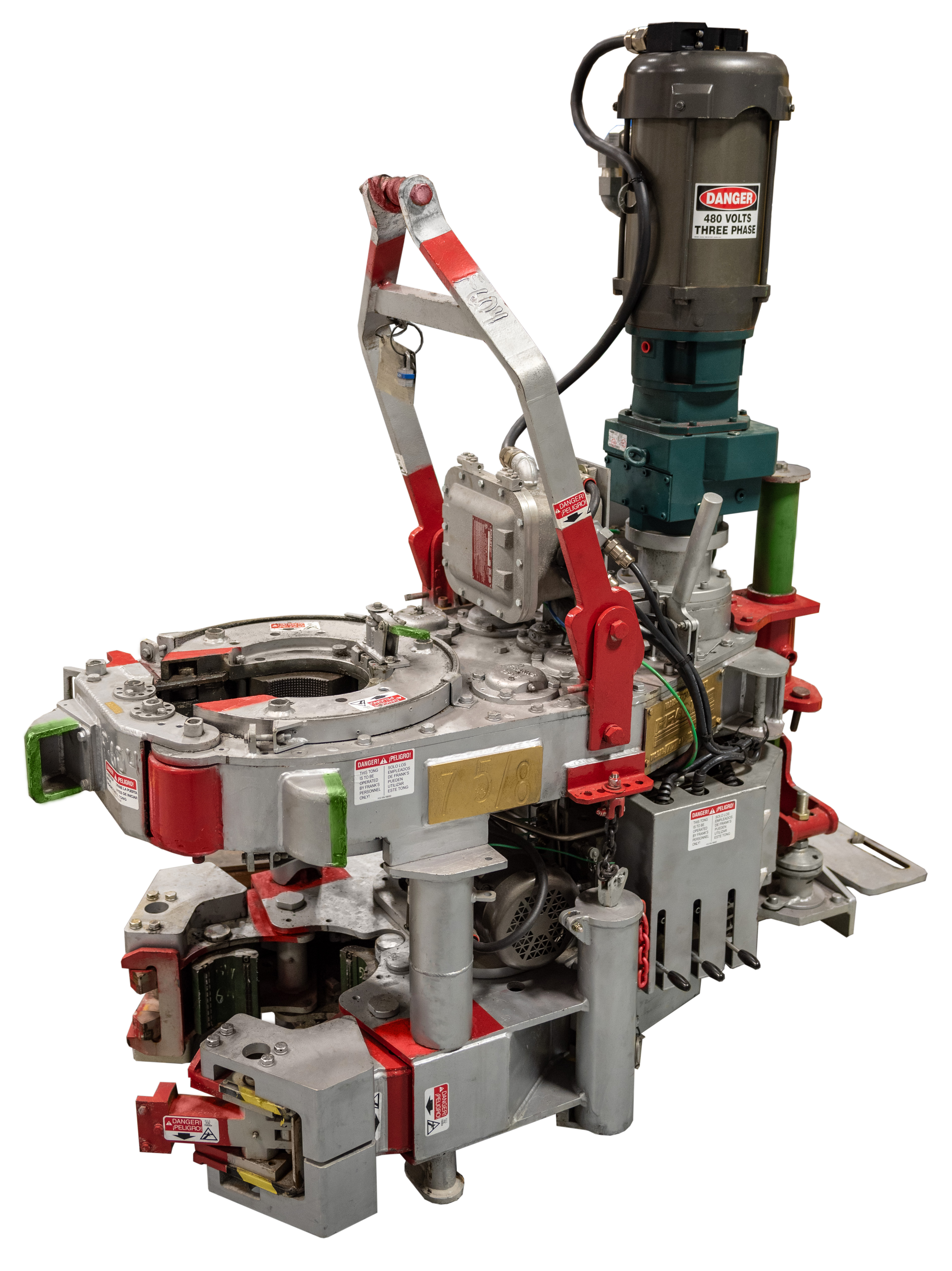

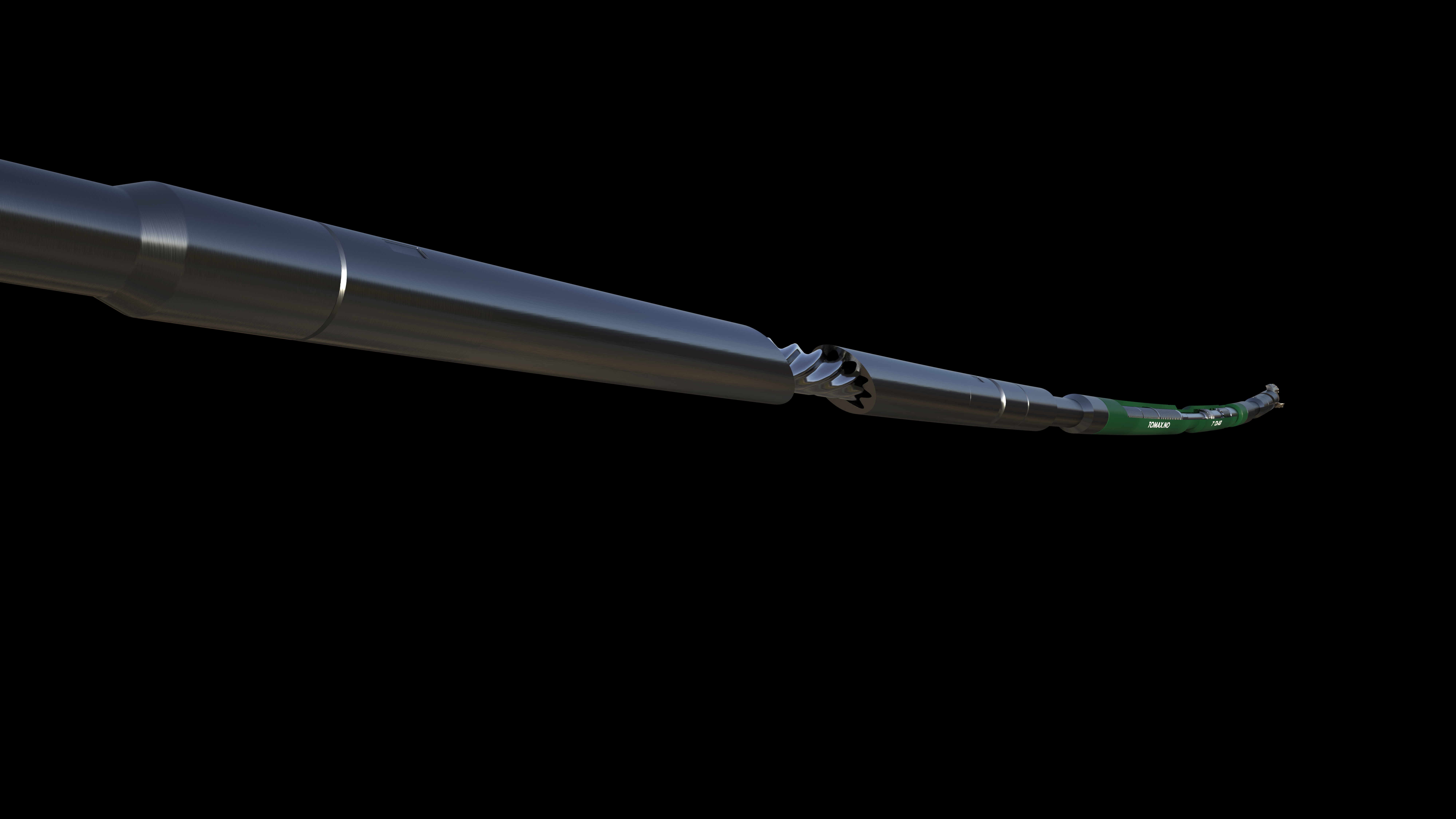

Drilling

Multiple problems can arise while drilling. Pointing out one example, Sam Shwayat, a technical and solutions specialist at DiverterPlus, told E&P a key component in improving drilling efficiency and controlling costs is stopping or preventing lost circulation.

"This is accomplished by the many available options of lost circulation material [LCM]; although most LCM types available in the market today do not address the amount of formation damage or the negative impact on cement bonding they can cause,” he said. “Through lab testing and field applications, degradable LCM has shown to be a cost-effective solution for not only stopping losses but also in addressing these two issues."

Many operators and service companies have formed relationships to address these issues and to keep up with the challenges operators face out in the field.

"The economics have forced both the operator and supplier to continually look for efficiency gains in their operations," said Timothy Armand, Newpark Drilling Fluids' president, North America. "Processes involving supply chain, logistics, seamless operations from a service provider as well as enhancing overall operational efficiency had to improve in order to make oil and gas exploration economical at current crude oil prices."

The following is a sampling of new products and services available for shale drilling.

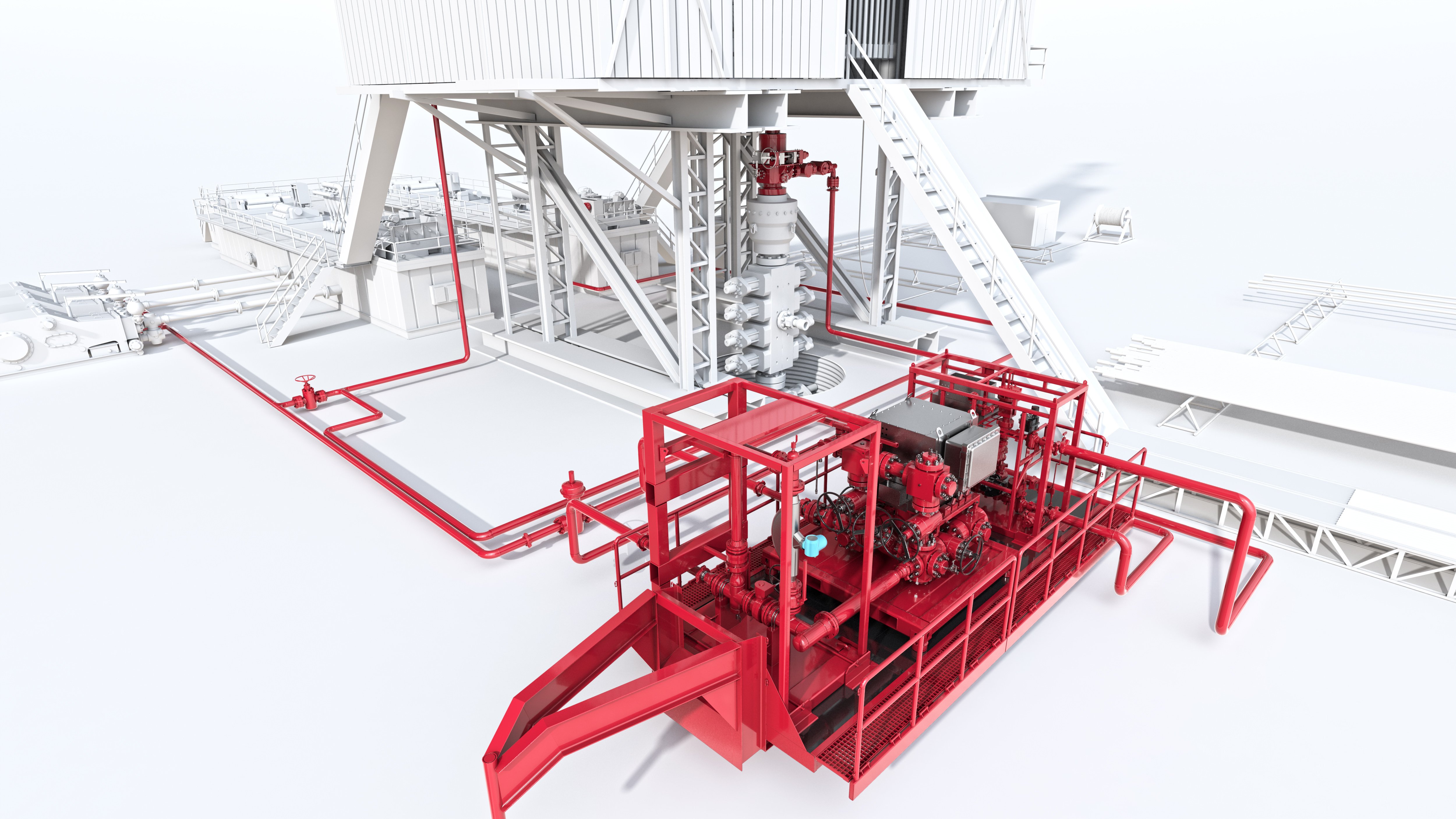

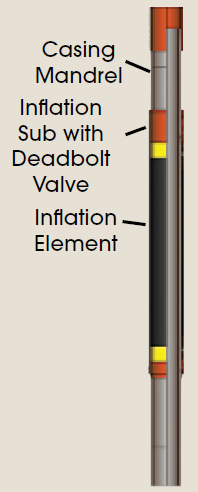

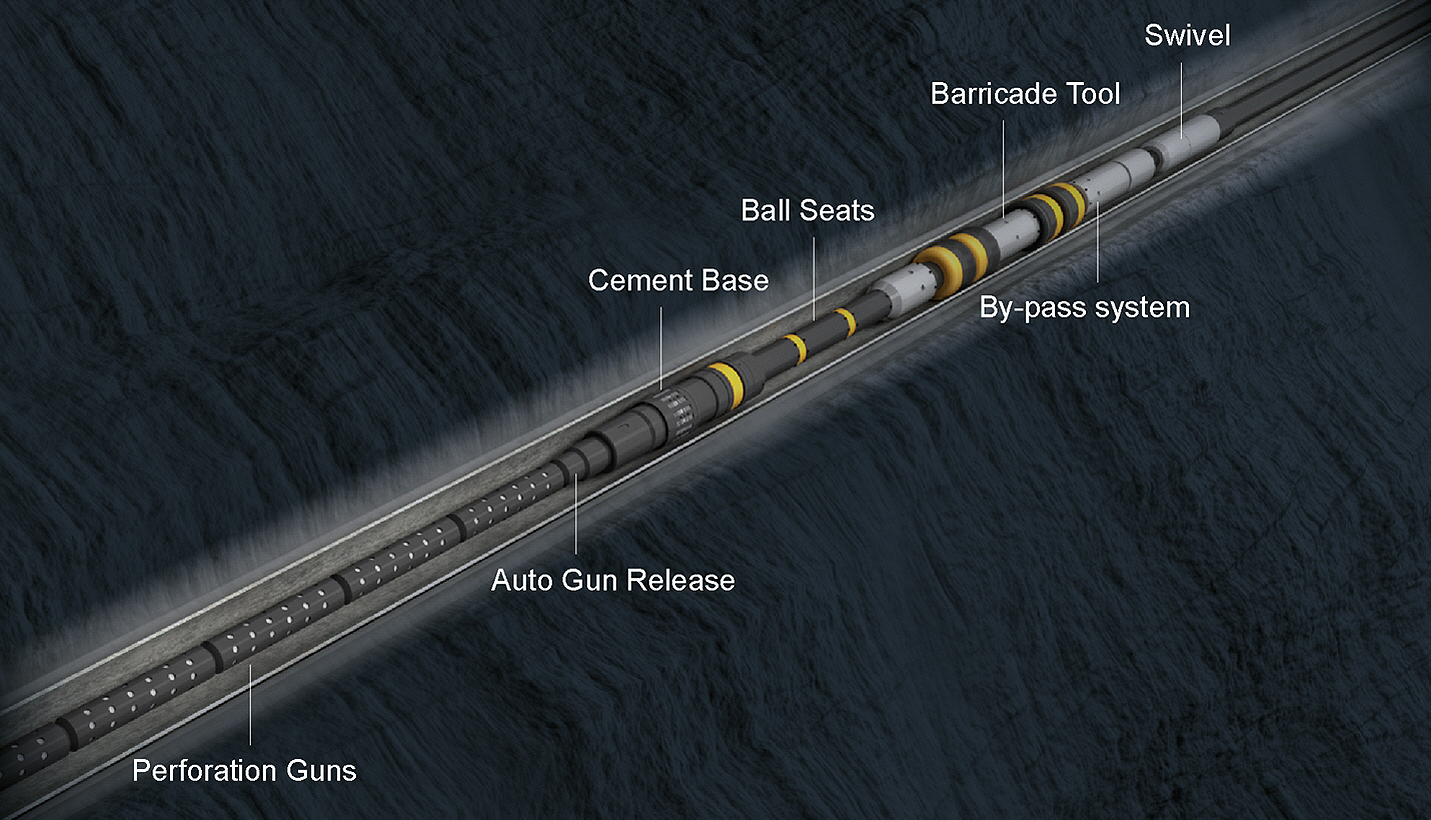

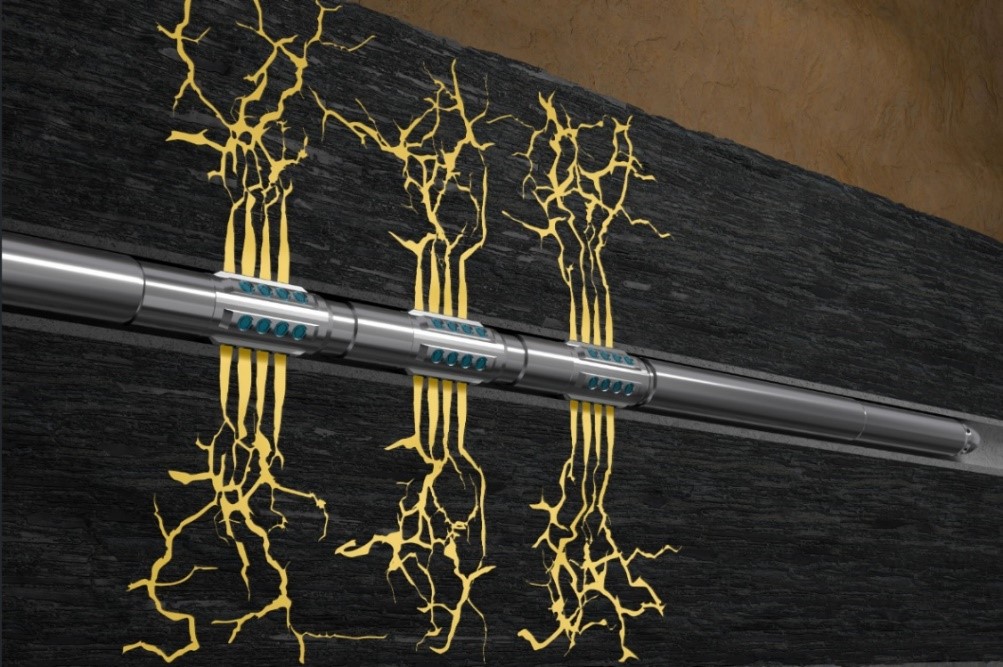

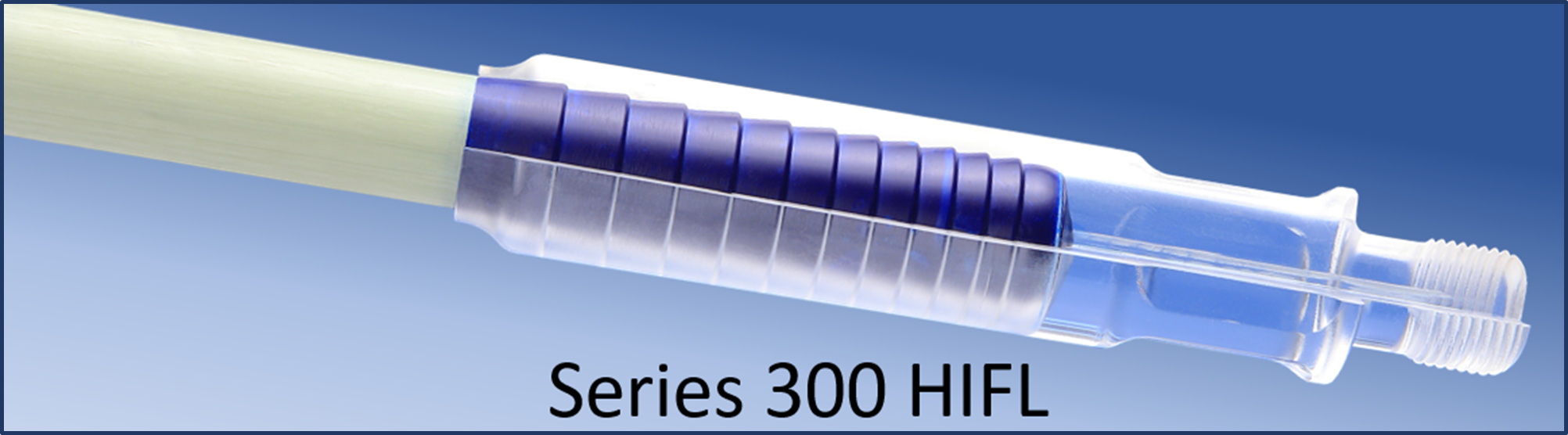

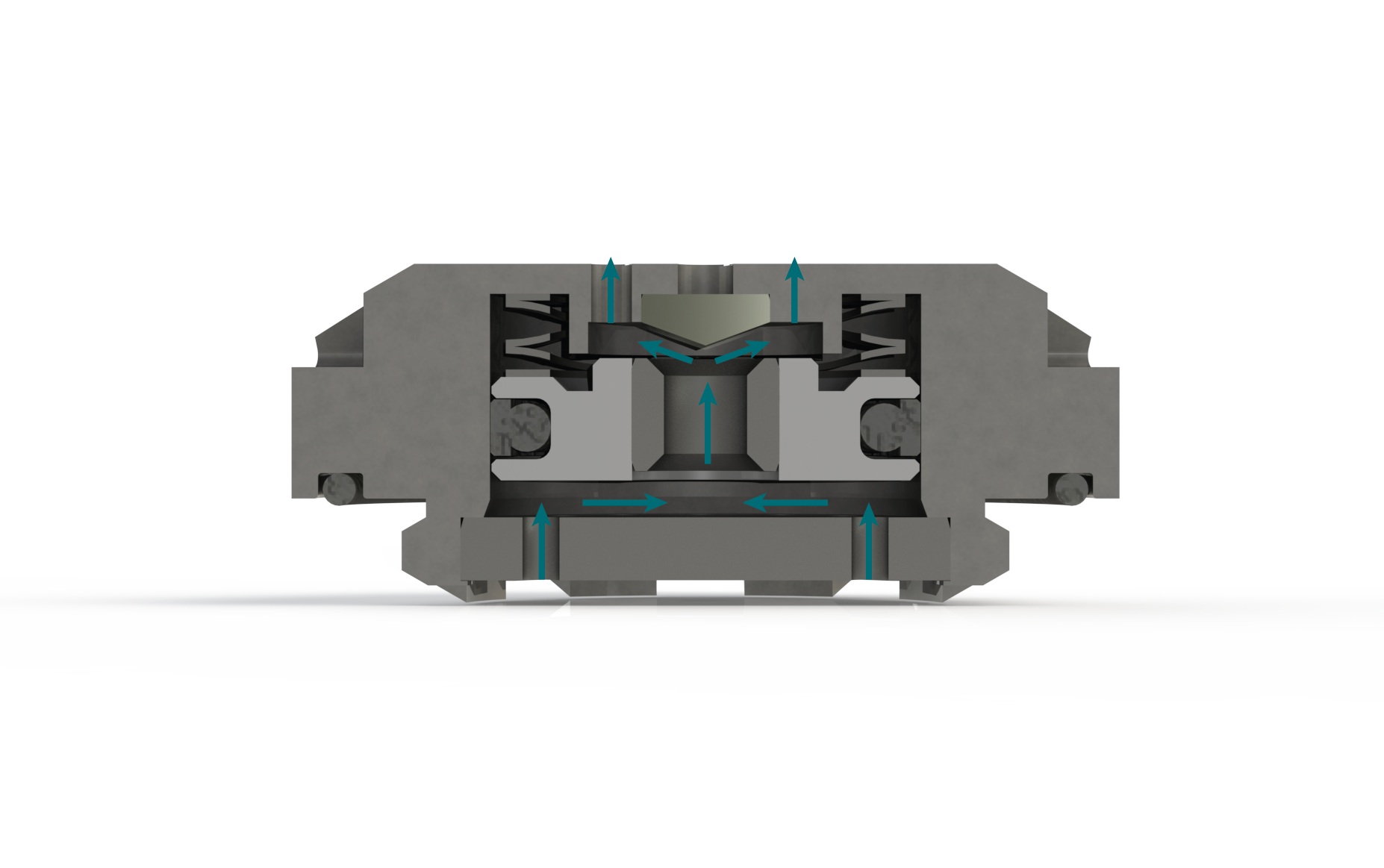

Completions

Completion tools are at the top of the list for significant technologies needed for a successful unconventional oil and gas operation.

"Optimizing your completion strategy is key to delivering high-performance wells on a consistent basis. Innovate or become obsolete," JD Schmidt, COO at Enhanced Energetics (formerly The GasGun LLC), told E&P.

Many service companies are continuing to develop and enhance well completion tools—innovations that are crucial to improving efficiencies.

"Completion costs and efficiency are the last domino to address as the industry aims to further reduce well costs and completion times," said Grant Ayo, vice president of AFGlobal’s NRG Pressure Pumping Technologies. "While incremental gains were achieved over the last decade of the shale boom, the market is still seeking an innovation that truly changes the dynamics of well completions. The solution lies in equipment that evolves completions from the diesel age to the digital age, giving the industry tools that improve horsepower density, asset life and machine intelligence."

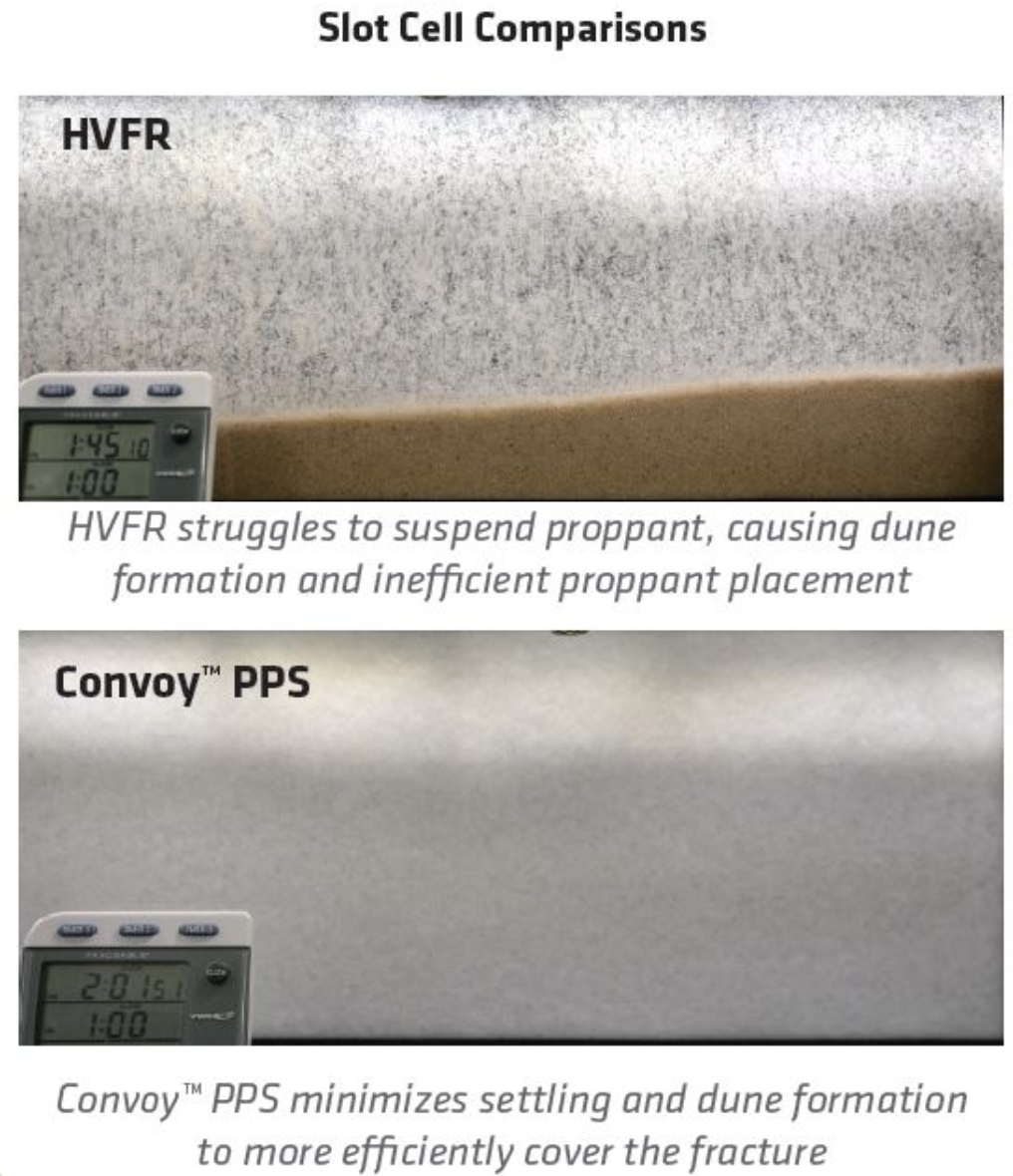

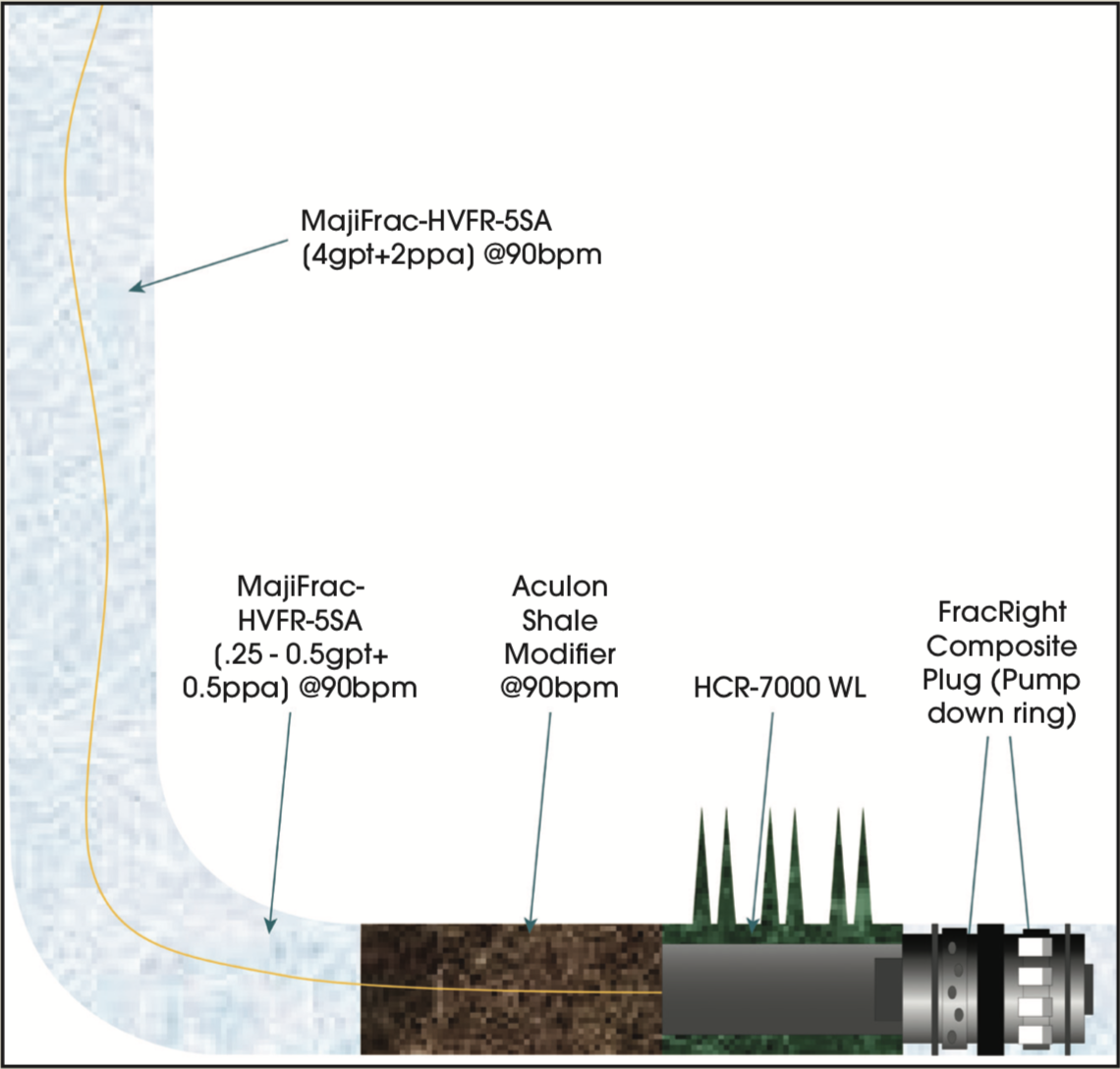

New technologies in the completions field are among the most important components in the overall cycle of producing a barrel of oil. The following is a sampling of the latest completions technologies.

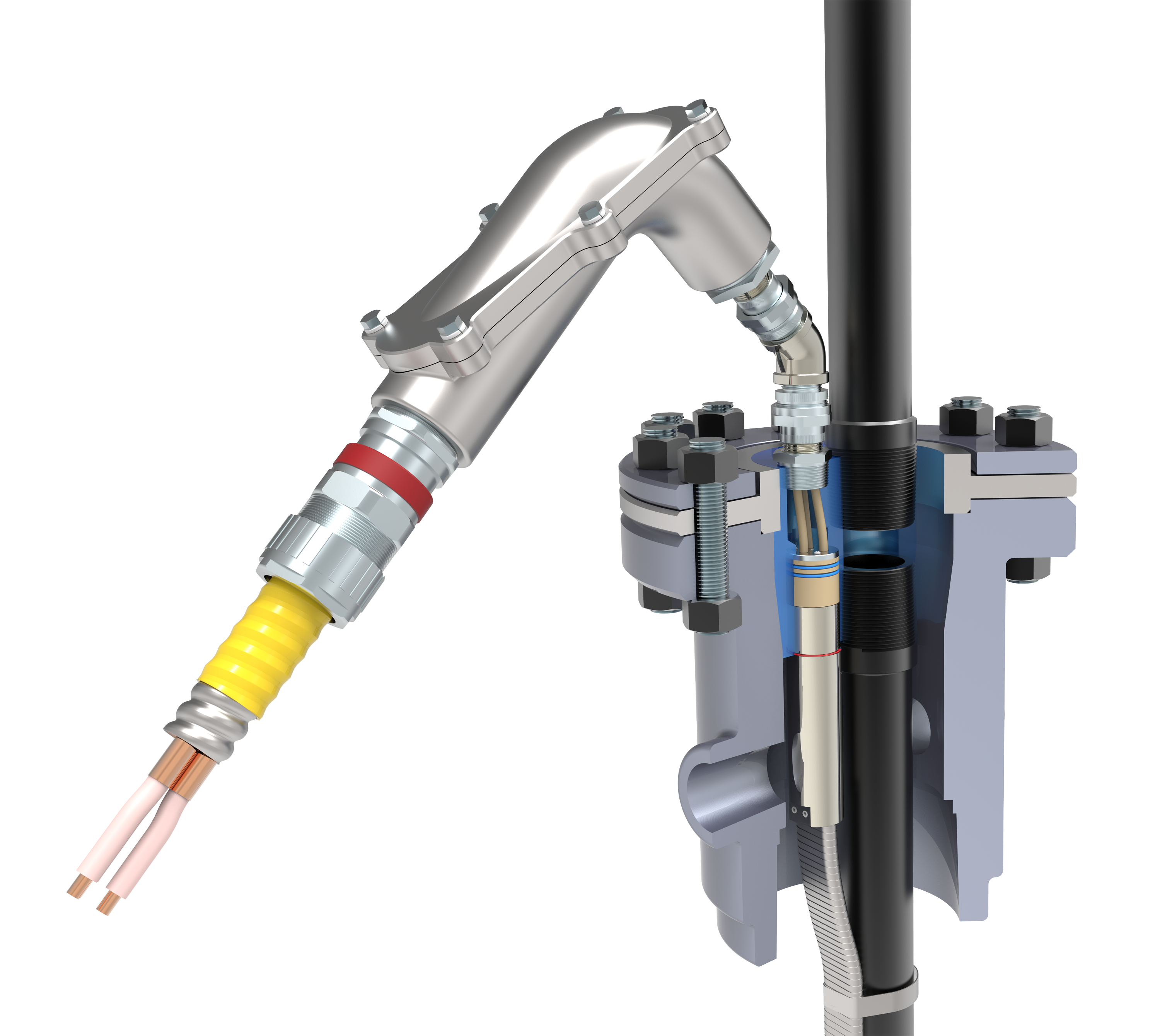

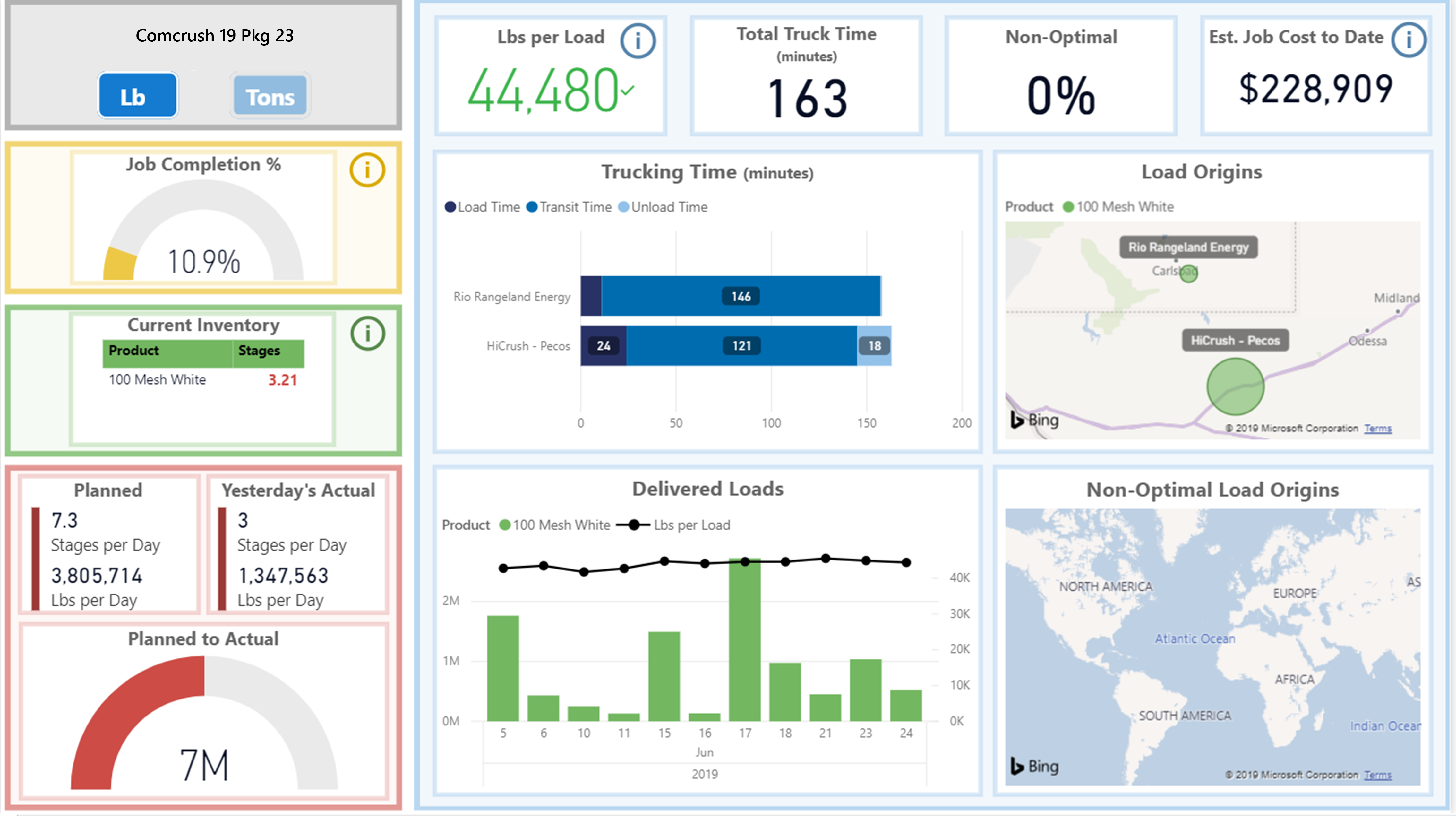

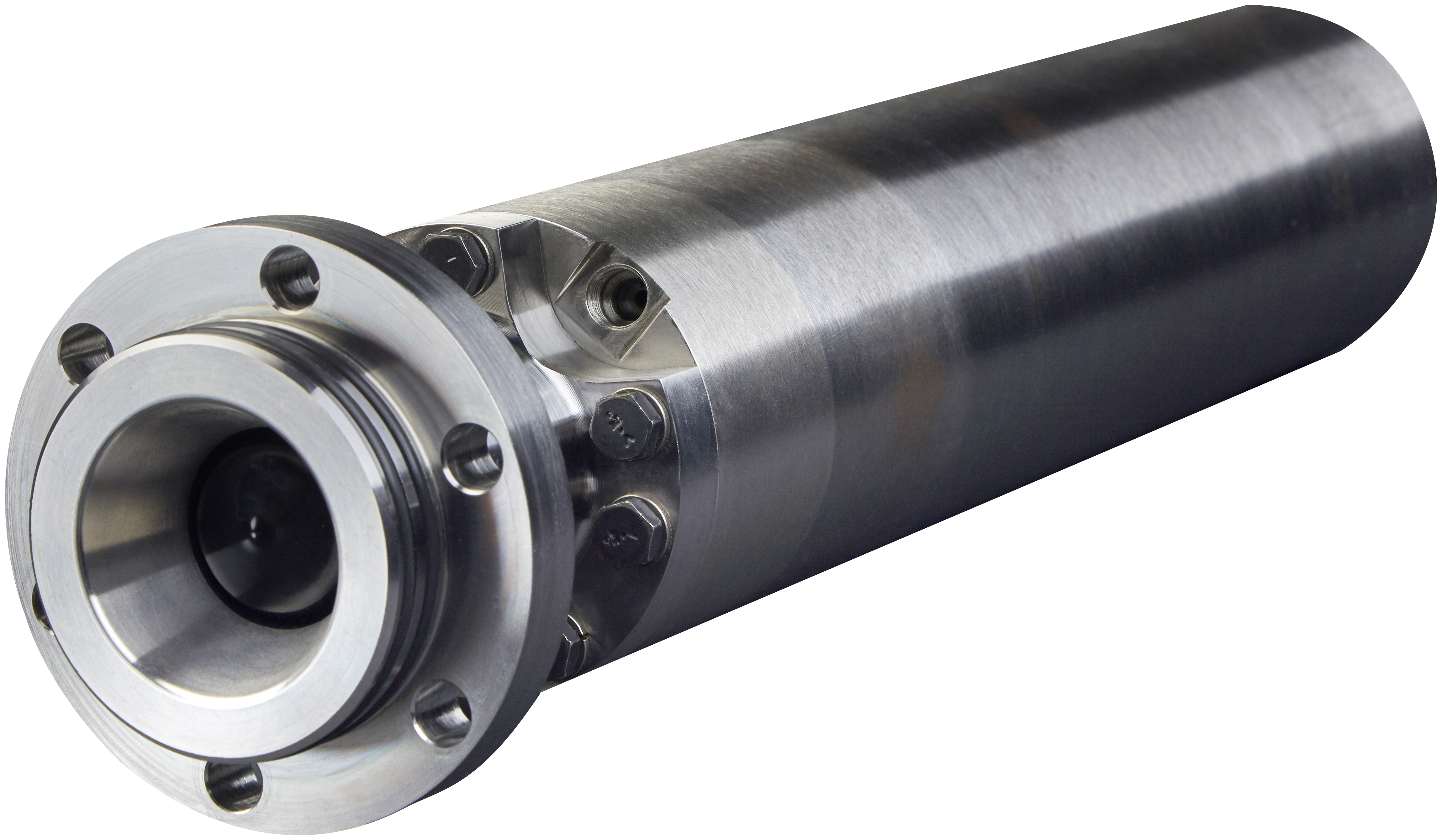

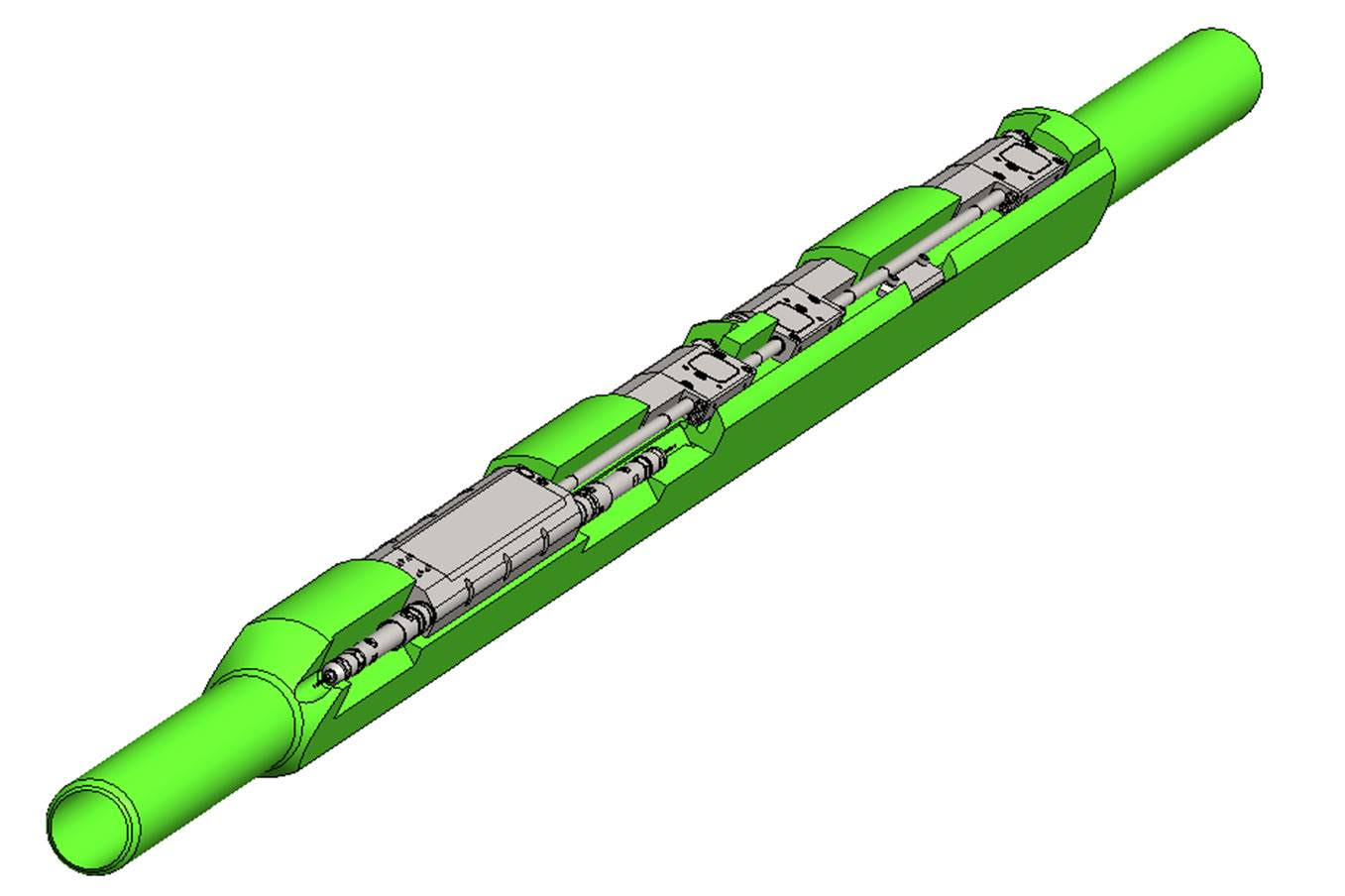

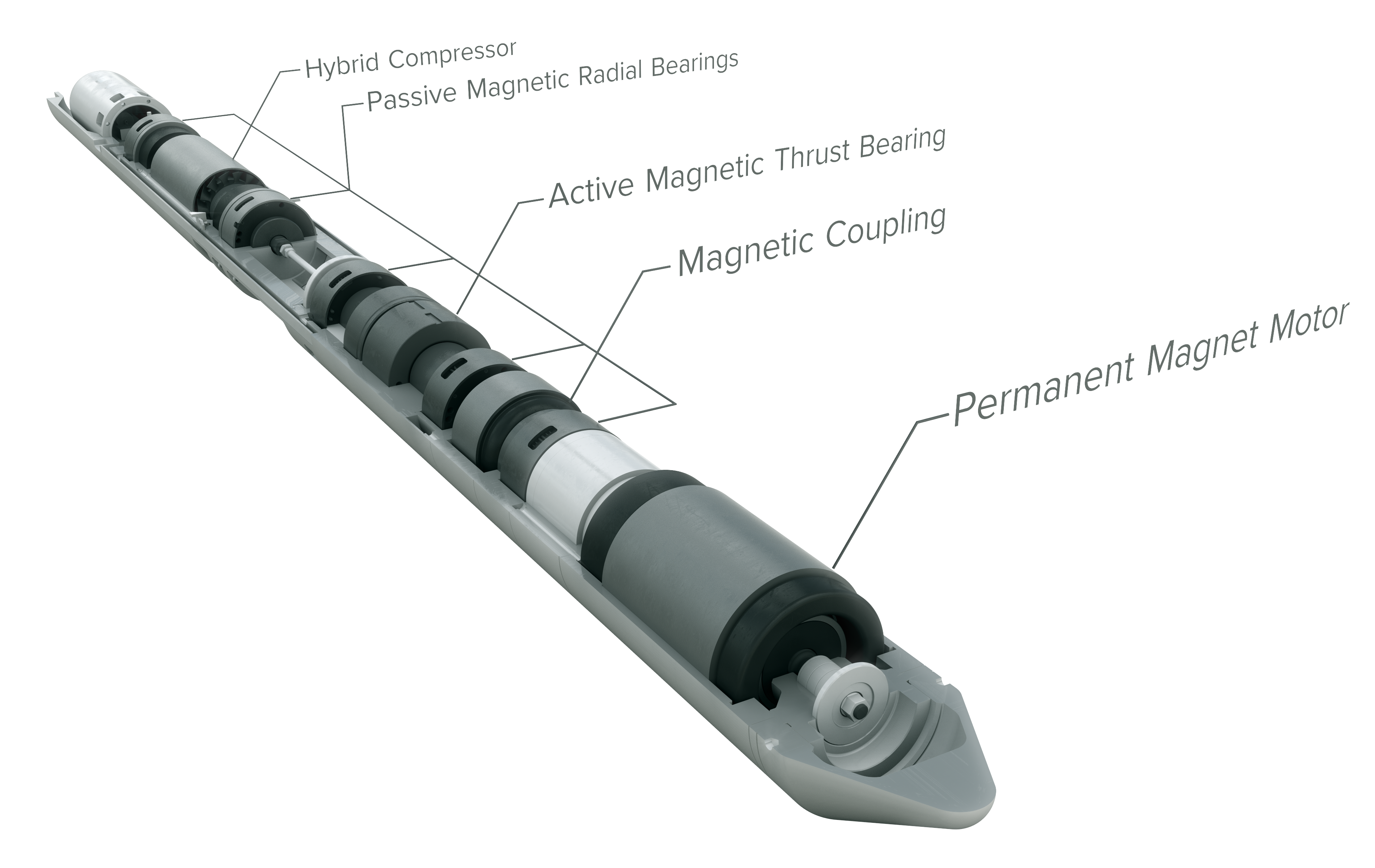

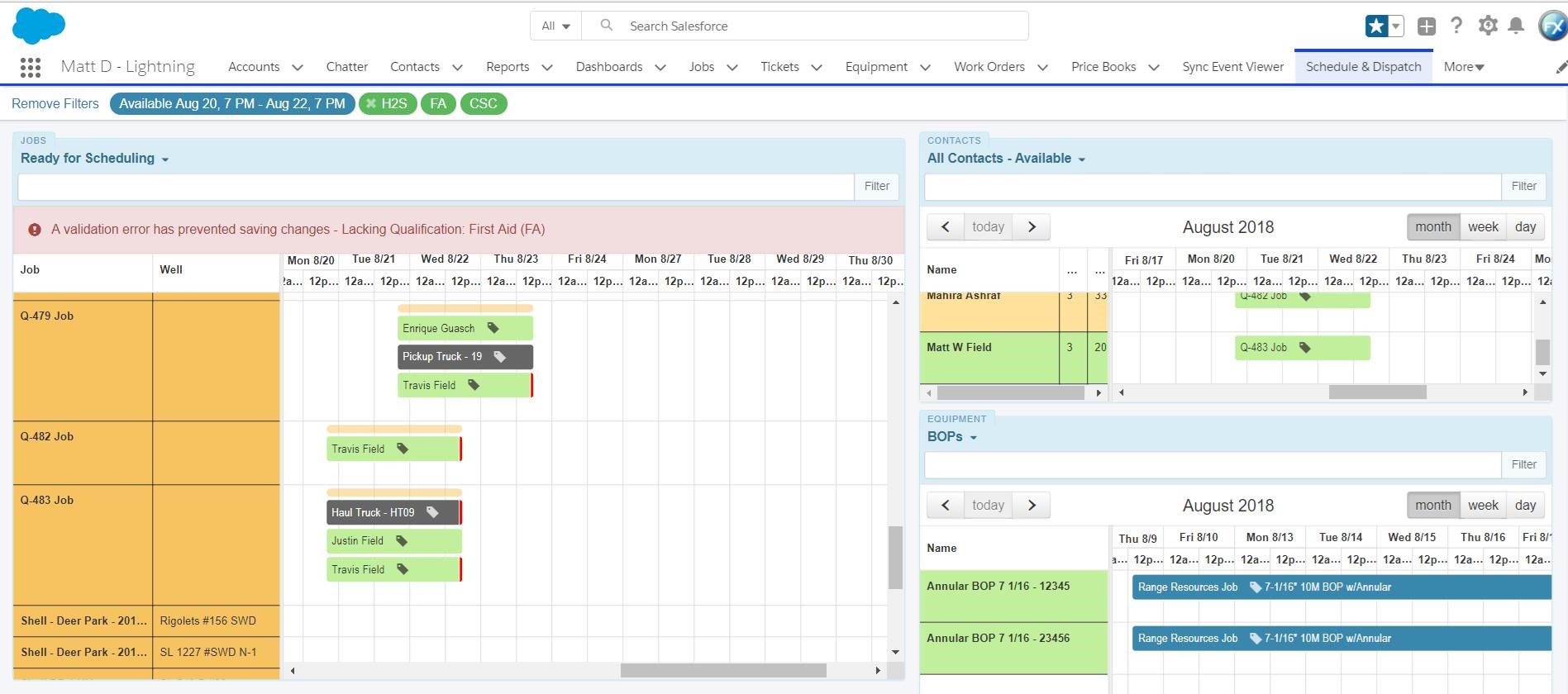

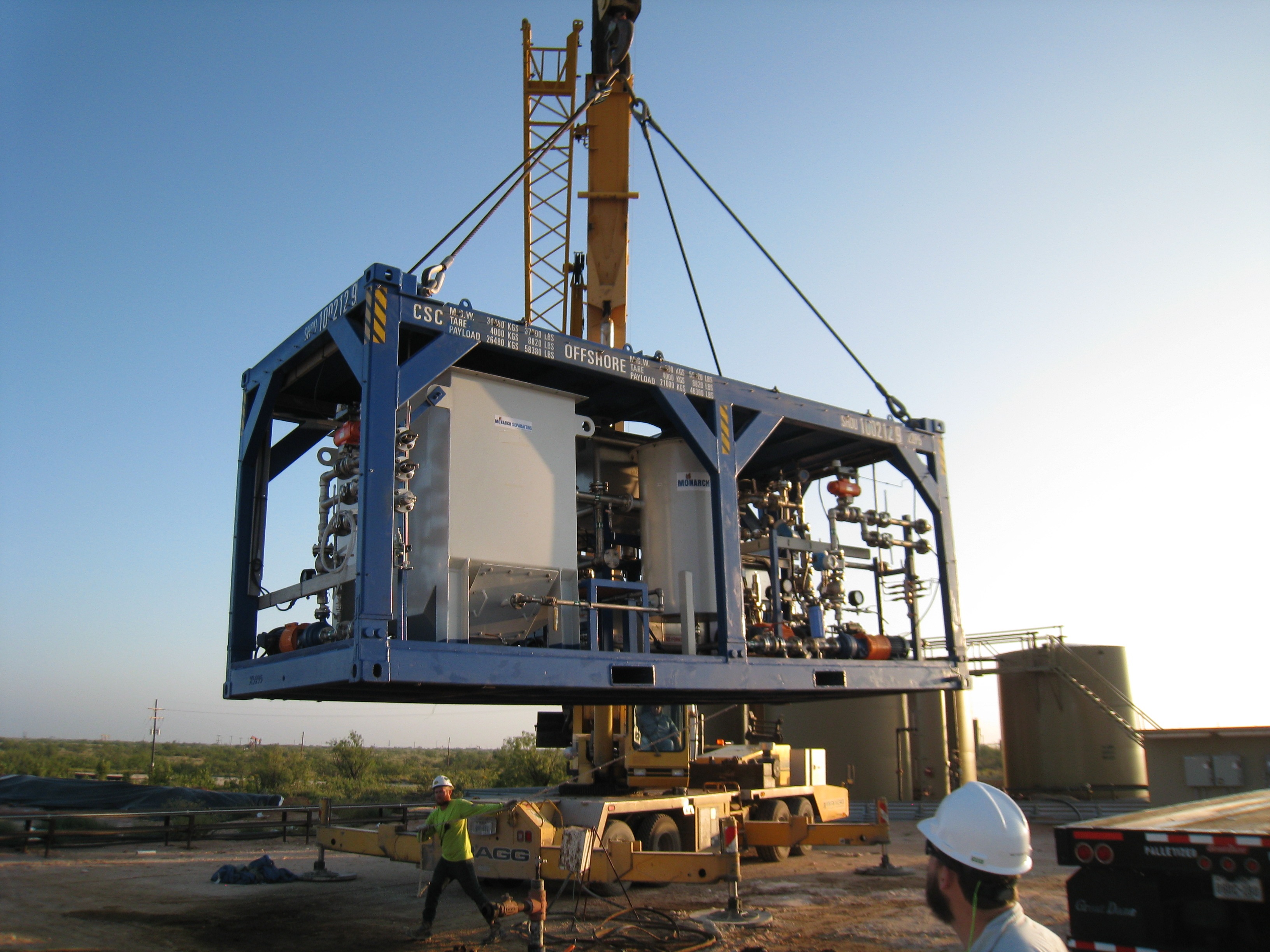

Production

Artificial lift, well intervention, flow assurance, production chemicals and emissions management are a few of the critical steps and technologies needed for an effective and thriving operation.

"Operators currently are able to drill and complete much faster and at lower costs today versus a decade ago," Herman Artinian, president and CEO of Upwing Energy, told E&P. "The next natural phase for the industry is to monetize by increasing production from existing assets and increasing recoverability through new production technologies."

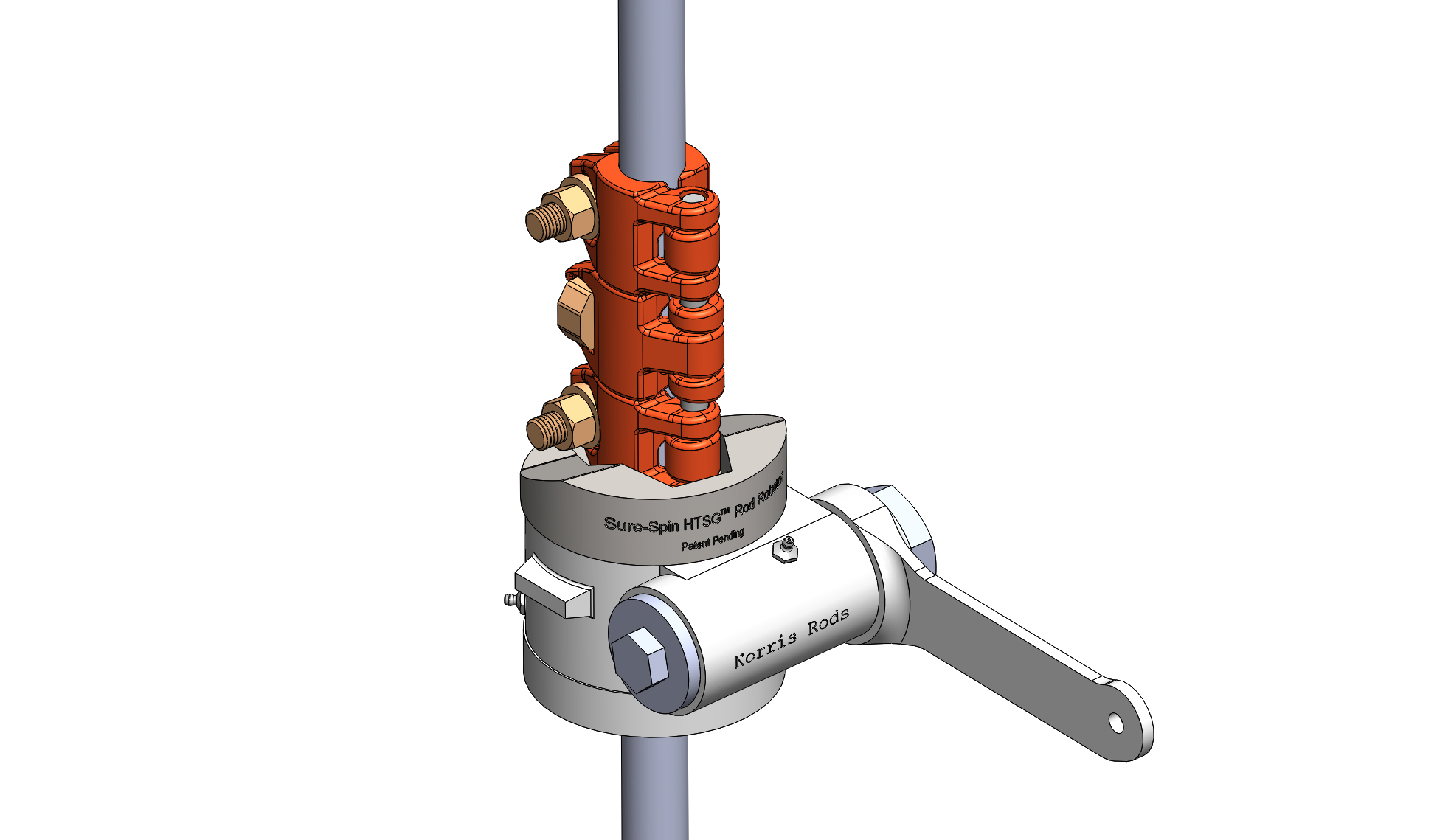

The tools and systems featured in E&P’s “Shale Technology Showcase” represent some of the latest efforts companies have made to increase production through more efficient processes, deeper wells and longer laterals. The following is a sampling of those new production technologies.

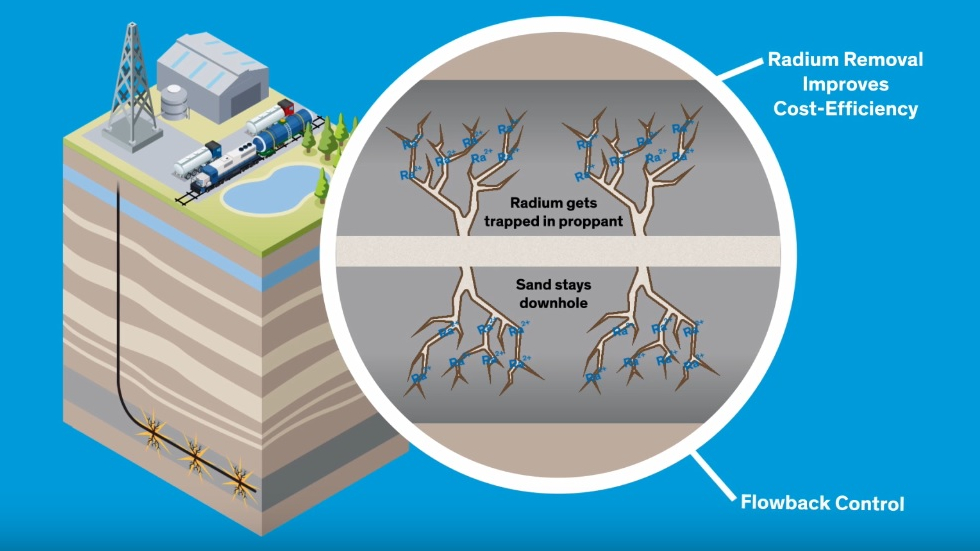

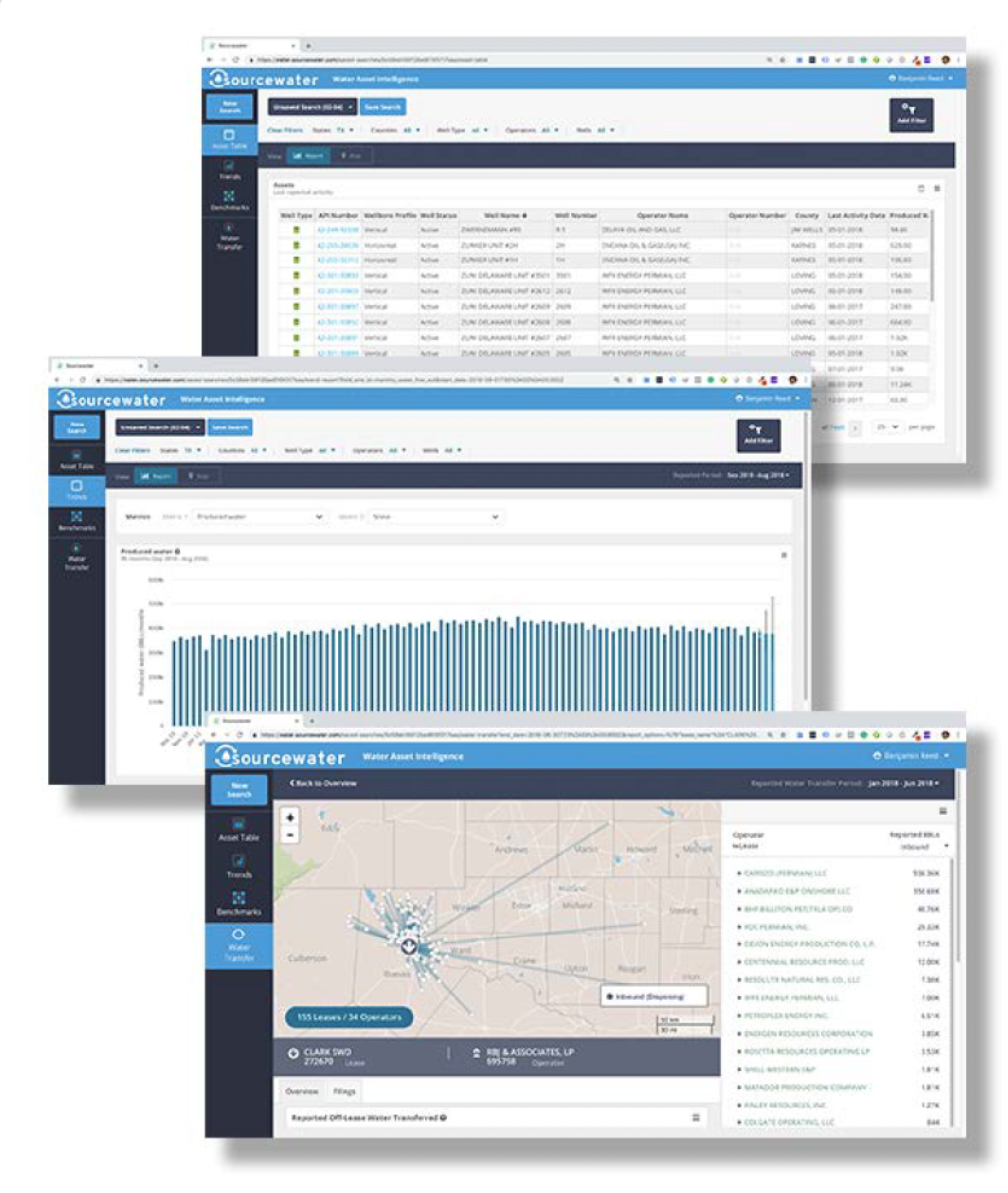

Water Management

Operators can be faced with a variety of water challenges, such as reducing and recycling produced water, minimizing freshwater use, reducing unwanted water production, treating produced water, and finding and transporting water for disposal and reuse.

“The ability to reduce and recycle produced water and minimize freshwater use can improve operator profitability and contribute to water conservation,” Halliburton stated on its website. “Globally, oil wells produce about 220 million BWPD [barrels of water per day]—roughly three barrels of water for every barrel of oil. In older fields, the water cut, or ratio of water-to-oil, can be 95% or higher. Managing this produced water is a great challenge for operators.”

The goal remains to optimize the use of natural resources, minimize waste and use water efficiently.

“Water is both a waste and a valuable commodity that is critical to all human activities,” Mark Wolf, director of onshore facilities at National Oilwell Varco, told E&P. “The future for water management in oil and gas will be finding ways to economically recycle water from waste back to something useful.”

The following is a sampling of some of the new technologies and products available for companies in the water management space.

The Shale Technology Showcase was compiled by Ariana Hurtado, associate managing editor of E&P magazine. She can be reached at ahurtado@hartenergy.com.

To advertise or contribute sponsored content to the Shale Technology Showcase, contact Danny Foster, executive director of digital media, at dfoster@hartenergy.com.