Over the last decade, the computerized application of statistical and other type analyses to a broad range of industrial disciplines has taken what were previously “arts,” — i.e., pursuits based on the intuitive insights of experienced individuals — and made them something more closely resembling a science. The impact of analytical applications can be seen clearly today in process, petroleum refining, and manufacturing industries. But they are also increasingly being applied to what still remains very much an art, that of upstream oil and gas production, to increase efficiency and recovery. Evidence of this trend was on display at the 2009 TIBCO Spotfire User Forum held last week in Houston, and will be so again at this week’s OSIsoft User Conference. To start, the impact of quantitative analyses already extends beyond industrial applications to impact many diverse aspects of modern life. In sports, it’s uncovered the unique talents of role players whose contributions don’t always show up on traditional stat sheets. It’s led to the defeat of even the grandest of chess grandmasters by computers like IBM’s legendary “Big Blue.” And on Wall Street the so-called “quants” have made billionaires of individuals formerly derided as nerds, while at the same time, in failing to foresee today’s unique economic landscape, given new credence to the old adage: “garbage in, garbage out.” While interesting themselves, these examples point to the fact that analytics are best applied in closed systems with a defined, albeit capacious, set of variables — like a chess board or a basketball court, as opposed to the global economy, which is much more affected by hard-to-define influences such as consumer psychology. By the same token, the circumscribed world of a refinery is more susceptible to statistical analysis than the bespoke environment of an oil reservoir. Understandably then, though progress is being made, skepticism remains as to how much can be done, analytically speaking, in the upstream petroleum sector. One of the more interesting presentations at the Spotfire event came from Erin Van Volkenburgh, Chevron reservoir engineer and Spotfire whiz, who has been using analytics to optimize nitrogen gas injection across a gas-capped oil field to improve recovery through pressure maintenance. Use of Spotfire DXP identified low-pressure, under-injected areas and graphically displayed needed operational changes to management. The resulting injection modifications flattened the field decline rate, for a marked improved recovery in oil and natural gas. As Van Volkenburgh said, she was able “to demonstrate the efficiency of increased injection by analyzing gas injection over time and across the field to identify patterns and potential improvements.” The analyses also were able to quantify the risk to recovery from an associated aquifer, and demonstrate relationships between injectors and producers. Van Volkenburgh added that the use of Spotfire solutions was instrumental in demonstrating to unit managers and partners the reservoir’s performance characteristics, although it took time and a number of presentations for them to gain confidence in what they were shown. At last year’s OSIsoft users conference, two men were walking into the opening session when one turned to the other and said, “He’s supposed to spend his time solving problems, not building spreadsheets.” The two were giving witness to a well-known fact: the most commonly used industrial decision-support tool remains the Microsoft Excel spreadsheet, despite its recognized limitations as a means to integration and collaboration. OSIsoft’s PI System data historian collects data from heterogeneous systems and places it in a context meaningful for decision makers. Data historians originated as special-purpose data repositories for environments in which vast quantities of time-series or temporal data are acquired and stored at very high rates. Historians allow users to archive and retrieve years of data in a fraction of the time of a conventional relational database. Their development led automation vendors to bundle data historians into DCS and other type control systems, and they are available as stand-alone solutions form application vendors as well. At this level, data historians are purely a commodity. It could be said that OSIsoft made the market for enterprise data historians, and for its 25 years of efforts the company today has revenues exceeding $100 million, while remaining privately held. But with the addition of an analysis framework and other capabilities, its solutions are much more than a commodity. In fact, the term “historian” is today inappropriate to the extent they have evolved to become real-time data delivery mechanisms, performing mathematical operations that aggregate and transform acquired data into operational intelligence for decision support. As AMR Research has put it, a historian today, “offers a platform for aggregating, consolidating, and recalibrating data from various systems in the production environment.” OSIsoft has considerable penetration in upstream oil & gas, but what is still not evident to many in the industry, said Cheryl Dugger, OSIsoft business development executive, oil & gas, is the role PI System can play in real-time, or near real-time, operations management and the value of “ad hoc analyses.” Compared to downstream oil & gas operations, said Dugger, “every oil field has its own complexities, with more variables, and even some that are unknown.” But she looks forward to the day, not so far distant, when upstream managers will more fully realize the analytic power of the PI System.

Recommended Reading

CEO: Coterra ‘Deeply Curious’ on M&A Amid E&P Consolidation Wave

2024-02-26 - Coterra Energy has yet to get in on the large-scale M&A wave sweeping across the Lower 48—but CEO Tom Jorden said Coterra is keeping an eye on acquisition opportunities.

Hess Corp. Boosts Bakken Output, Drilling Ahead of Chevron Merger

2024-01-31 - Hess Corp. increased its drilling activity and output from the Bakken play of North Dakota during the fourth quarter, the E&P reported in its latest earnings.

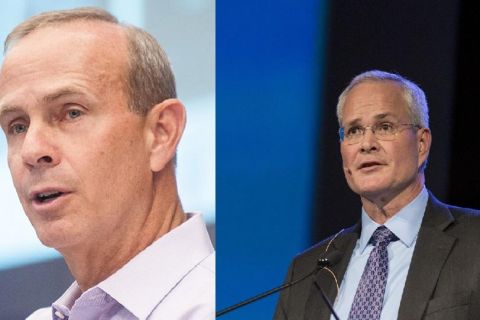

Exxon, Chevron Tapping Permian for Output Growth in ‘24

2024-02-02 - Exxon Mobil and Chevron plan to tap West Texas and New Mexico for oil and gas production growth in 2024, the U.S. majors reported in their latest earnings.

E&P Earnings Season Proves Up Stronger Efficiencies, Profits

2024-04-04 - The 2024 outlook for E&Ps largely surprises to the upside with conservative budgets and steady volumes.

Petrie Partners: A Small Wonder

2024-02-01 - Petrie Partners may not be the biggest or flashiest investment bank on the block, but after over two decades, its executives have been around the block more than most.