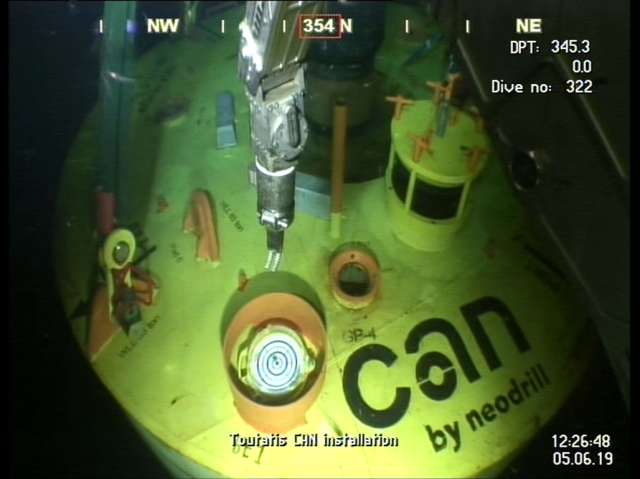

(Source: Wintershall Dea GmbH)

Neodrill, the leader in pre-rig technology solutions, has together with Baker Hughes, performed the world’s first cut and recover operation for Wintershall Dea Norge in the Norwegian Sea on June 15.

Rig time was reduced by an estimated 12 hours, with work to cut the surface casing moved off the critical path of the rig schedule.

The project enabled the rig to abandon the well site as soon as the cement plugs were in place. The surface casing was then cut from a vessel, using Baker Hughes’ new casing cutting tool. This optimized process removes the need for unnecessary, expensive rig time in the abandonment phase.

The new ‘cut and recover’ service will now be offered as part of Neodrill’s CAN-complete. The CAN-complete sees Neodrill offer a full service engineering, procurement, construction and installation (EPCI) solution to manage all aspects of a CAN installation, reducing the operator’s internal resource requirements and overheads. With the inclusion of cut and recover, the CAN-complete will now also reduce rig time in the abandonment phase by allowing the rig to leave the well site after setting the cement plugs.

“With every project, we carefully consider our approach and how it can be improved to drive forward even more cost savings for our clients. Our CAN technology has already been proven to reduce rig time by 2 to 4 days to establish a tophole foundation and now we are pleased to be reducing time in the abandonment phase too. As a team, we are very proud to have been involved in the world’s first ‘cut and recover’ operation. Working with Baker Hughes, we removed 12 hours from the rig schedule and delivered real cost savings for Wintershall Dea as a result,” Jostein Aleksanderse, Neodrill’s CEO, said.

Recommended Reading

EIA: Permian, Bakken Associated Gas Growth Pressures NatGas Producers

2024-04-18 - Near-record associated gas volumes from U.S. oil basins continue to put pressure on dry gas producers, which are curtailing output and cutting rigs.

Benchmark Closes Anadarko Deal, Hunts for More M&A

2024-04-17 - Benchmark Energy II closed a $145 million acquisition of western Anadarko Basin assets—and the company is hunting for more low-decline, mature assets to acquire.

‘Monster’ Gas: Aethon’s 16,000-foot Dive in Haynesville West

2024-04-09 - Aethon Energy’s COO described challenges in the far western Haynesville stepout, while other operators opened their books on the latest in the legacy Haynesville at Hart Energy’s DUG GAS+ Conference and Expo in Shreveport, Louisiana.

Mighty Midland Still Beckons Dealmakers

2024-04-05 - The Midland Basin is the center of U.S. oil drilling activity. But only those with the biggest balance sheets can afford to buy in the basin's core, following a historic consolidation trend.