Baker Hughes, a GE company (NYSE: BHGE), has committed to reducing its CO2 equivalent emissions 50% by 2030, achieving net-zero CO2 equivalent emissions by 2050, the company said Jan. 28 in a news release.

The news was announced during the company’s annual meeting in Florence, Italy.

BHGE also said it will invest in its portfolio of advanced technologies to assist customers with reducing their carbon footprint.

The company said it has already achieved a 26% reduction in its emissions since 2012 through a commitment to new technology and operational efficiencies. BHGE will continue to employ emissions reduction initiatives across manufacturing, supply chain, logistics, energy sourcing and generation. BHGE has established a global additive manufacturing technology network with a mission to bring commercial-scale production closer to customers, reducing transportation impact and associated emissions, the company said in the release.

“Managing carbon emissions is an important strategic focus for our business. We believe we have an important role to play as an industry leader and partner,” Lorenzo Simonelli, chairman and CEO of BHGE, said in the release. “BHGE has a long legacy of pushing the boundaries of technology and operating efficiency. Today we take this to the next level by committing to ambitious new goals for ourselves, and to providing lower carbon solutions expected by customers and society.”

As part of the effort, BHGE’s Gaffney, Cline and Associates launched a new Carbon Management Practice, offering quantitative assessment of carbon intensity, evaluation of carbon solutions and the accreditation of emission reductions. BHGE said this new practice helps governments, energy companies and the financial community understand and solve energy transition issues related to oil and gas resources, assets and investments.

In addition, BHGE announced new technologies that support operators’ efforts to reduce their carbon footprint. These include LUMEN, a suite of methane monitoring and inspection solutions capable of streaming live data from sensors to a cloud-based software dashboard for real-time results. The company also announced an agreement with H2U, an Australian hydrogen infrastructure developer, to configure BHGE’s NovaLT gas turbine generator technology to operate 100% on hydrogen for the Port Lincoln Project, a green hydrogen power plant facility in South Australia.

BHGE said the new technologies build its expanding lower-carbon technology portfolio. These include modular gas processing; the LM9000 gas turbine, which was designed to allow LNG train startup in the pressurized condition without venting process gas; integrated compressor line, which operates with zero emissions; flare.iQ, which provides near-continuous control of downstream flare performance by optimizing combustion efficiency; and NextSource Modular CO2 Capture, which converts thermal energy from rich burn Waukesha engine exhaust to provide low cost CO2 for oil and gas consumers.

Recommended Reading

US Eases Tailpipe Rules, Slows EV Transition Through 2030

2024-03-20 - The Biden administration is unveiling final rules on March 20 that make it easier for automakers to continue selling gas-powered models and slows the projected transition to electric vehicles through 2030.

US EPA Removes Existing Gas Plants From Proposed Carbon Rule

2024-02-29 - The U.S. Environmental Protection Agency will exclude existing natural gas power plants from its proposed carbon regulations that it plans to finalize in April.

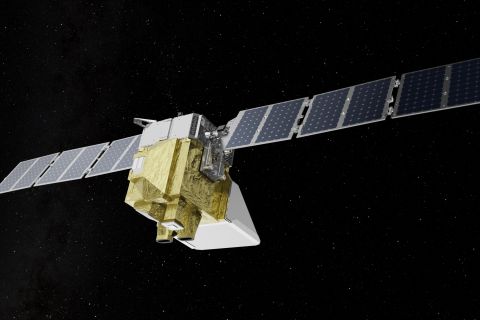

Markman: Is MethaneSAT Watching You? Yes.

2024-04-05 - EDF’s MethaneSAT is the first satellite devoted exclusively to methane and it is targeting the oil and gas space.

Tax Credit’s Silence on Blue Hydrogen Adds Uncertainty

2024-01-31 - Proposed rules for the 45V hydrogen production tax credit leave blue hydrogen up in the air, but producers planning to use natural gas with carbon capture and storage have options.

NAPE: In Basins Familiar to E&Ps, Lithium Rush Offers Little Gold

2024-02-07 - A quest for sources of lithium comes as the lucrative element is expected to play a part in global efforts to lower emissions, but in many areas the economics are challenging.