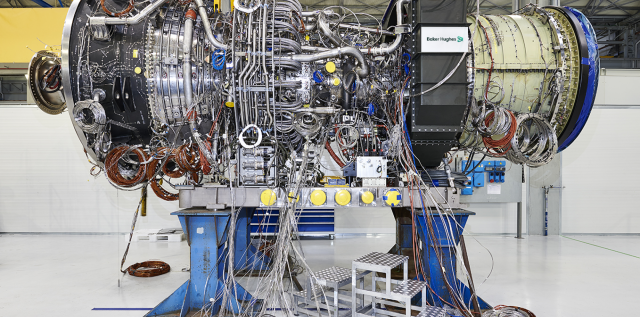

Baker Hughes LM9000 gas turbine during assembly. (Source: Baker Hughes Co.)

Baker Hughes revealed the completion of the First Engine to Test (FETT) for the LM9000 aeroderivative gas turbine on June 9. The test took place at the company’s advanced turbomachinery testing facilities in Florence and Massa, Italy.

In 2018, Novatek selected Baker Hughes for the supply of LM9000 aeroderivative gas turbines for the Arctic LNG 2 project. The successful FETT completion paves the way for the supply of the same turbines for Novatek’s new LNG projects.

The successful test completion confirms the LM9000 as the most powerful and most efficient aeroderivative gas turbine in its class with simple cycle efficiency in excess of 44% and a power output 15% higher compared to industry peers. This efficiency is key to driving lower carbon intensity and combined with lower NOx emissions (15 ppm in dry condition, 40% lower than competing technology) makes for a more environmentally sensitive solution. A small footprint and innovative module design for fast and easy maintenance make the LM9000 the gas turbine of choice for all mechanical drive and power generation applications.

“This is a crucial milestone for the ongoing development of our innovative LM9000 turbine technology and an important step forward in the on time delivery of Arctic LNG 2, which continues to be on track despite COVID-19 challenges,” Rod Christie, executive vice president, turbomachinery and process solutions at Baker Hughes, said. “Building on our 30-year-plus track record of delivering highly efficient and reliable LNG technology, the FETT results are a strong recognition of the LM9000’s flexibility, reliability and suitability for major LNG projects around the world such as Arctic LNG 2.”

The successful FETT leveraged Baker Hughes’ turbomachinery remote testing capabilities to overcome travel restrictions imposed by COVID-19. More than 80 experts from various locations were connected remotely to perform the full speed and full load test. In addition, remote witness technology, such as smart glasses and helmets, enabled real-time and seamless sharing of machine inspections and virtual testing performed in Massa with the extended teams around the world.

Baker Hughes’ overall scope of work for Arctic LNG 2 includes the supply of turbomachinery equipment for power generation and three liquefaction trains on gravity-based structures (GBS) that will produce 6.6 million tons of LNG per annum each, for a total production of 19.8 MTPA.

Recommended Reading

US Drillers Add Oil, Gas Rigs for First Time in Five Weeks

2024-04-19 - The oil and gas rig count, an early indicator of future output, rose by two to 619 in the week to April 19.

Strike Energy Updates 3D Seismic Acquisition in Perth Basin

2024-04-19 - Strike Energy completed its 3D seismic acquisition of Ocean Hill on schedule and under budget, the company said.

Santos’ Pikka Phase 1 in Alaska to Deliver First Oil by 2026

2024-04-18 - Australia's Santos expects first oil to flow from the 80,000 bbl/d Pikka Phase 1 project in Alaska by 2026, diversifying Santos' portfolio and reducing geographic concentration risk.

Iraq to Seek Bids for Oil, Gas Contracts April 27

2024-04-18 - Iraq will auction 30 new oil and gas projects in two licensing rounds distributed across the country.

Vår Energi Hits Oil with Ringhorne North

2024-04-17 - Vår Energi’s North Sea discovery de-risks drilling prospects in the area and could be tied back to Balder area infrastructure.