Aker BP will be the first user of the new technology Optime Subsea has developed that removes umbilical controlled tubing hanger operations, the company said on May 29. The technology increases safety and reduces operational time, cost, and environmental risk, according to Optime.

Optime’s relationship with Aker BP started with its innovative subsea controls and intervention light system (SCILS) on the semisubmersible drilling rig, Deepsea Nordkapp, owned and operated by Odfjell Drilling. This collaboration has now been extended with Aker BP bringing Optime’s remotely operated controls system (ROCS) onboard this same rig.

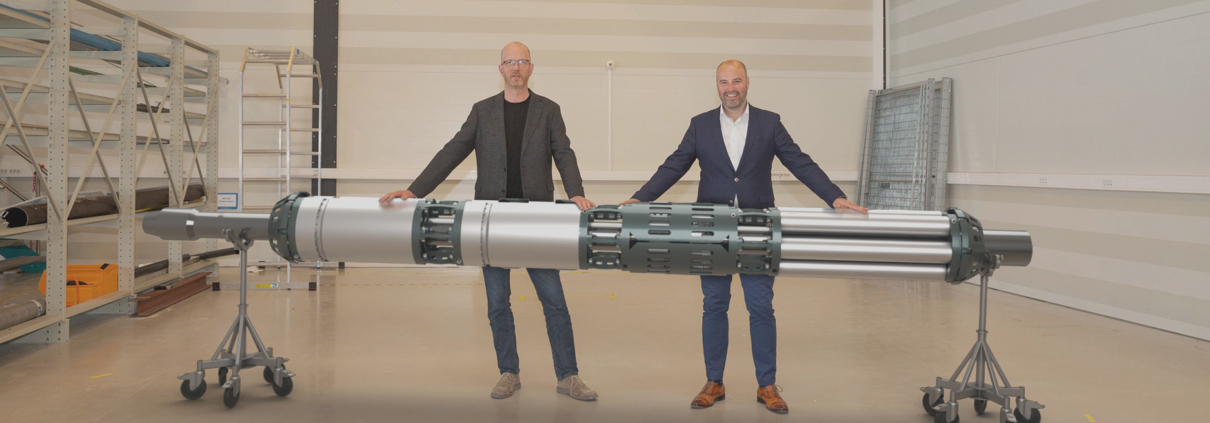

Controlling the tubing hanger running tool is currently done through a dedicated umbilical controlled from a large topside hydraulic unit. When deploying, the umbilical is clamped to the riser for increased stabilization. The operation is traditionally time-consuming, and the clamping will result in hours of additional higher-risk operations. Using the ROCS will significantly reduce the time spent on this operation. Optime’s ROCS offers the functionality of the same controls to the tubing hanger, without the topside hydraulic unit and without a large, heavy and costly umbilical and controls system.

“Until completing a few runs we will not be able to affirmatively state the total days in savings for subsea well completions, but we are convinced that this system will provide Aker BP and all other operators days, not hours, in savings, for every single well. Although today’s market is hard to predict, we are definitely able to see the future with this system being ready by end of the year—there will be tremendous industry wide cost savings for everyone,” Trond Løkka, Optime’s business development manager, said.

Recommended Reading

Drilling Tech Rides a Wave

2024-01-30 - Can new designs, automation and aerospace inspiration boost drilling results?

Tech Trends: Autonomous Drone Aims to Disrupt Subsea Inspection

2024-01-30 - The partners in the project are working to usher in a new era of inspection efficiencies.

TGS, SLB to Conduct Engagement Phase 5 in GoM

2024-02-05 - TGS and SLB’s seventh program within the joint venture involves the acquisition of 157 Outer Continental Shelf blocks.

2023-2025 Subsea Tieback Round-Up

2024-02-06 - Here's a look at subsea tieback projects across the globe. The first in a two-part series, this report highlights some of the subsea tiebacks scheduled to be online by 2025.

StimStixx, Hunting Titan Partner on Well Perforation, Acidizing

2024-02-07 - The strategic partnership between StimStixx Technologies and Hunting Titan will increase well treatments and reduce costs, the companies said.