Acoustic Data, a global leader in wireless well technology, has developed a remote deployment model for its SonicGauge wireless monitoring system to overcome travel restrictions relating to COVID-19, the company said on April 27.

The solution enables operators to self-install their real-time wireless downhole monitoring system without requiring specialist engineers onsite.

With much of the industry’s workforce grounded, Acoustic Data is offering full operational support in real-time from its U.K. headquarters. In conjunction with online training videos, operators will now be able to install the pre-packaged and pre-programmed technology in standard well installations, from underground gas storage through to production and monitoring wells.

“For how long the lockdown will continue is uncertain; however, we can anticipate extended restrictions on personnel deployment—particularly for offshore and remote locations—and a drive to minimize operational expenditure for the foreseeable future,” Matthew Norgate, COO of Acoustic Data, said. “In this environment, optimizing asset performance utilizing downhole well data is more critical than ever, so we have developed this deployment model for both the SonicGauge and Barracuda HEX-Hanger to give operators a cost-effective data solution in this period of limited mobility. This methodology is a testament to the portability and simplicity of the technology.”

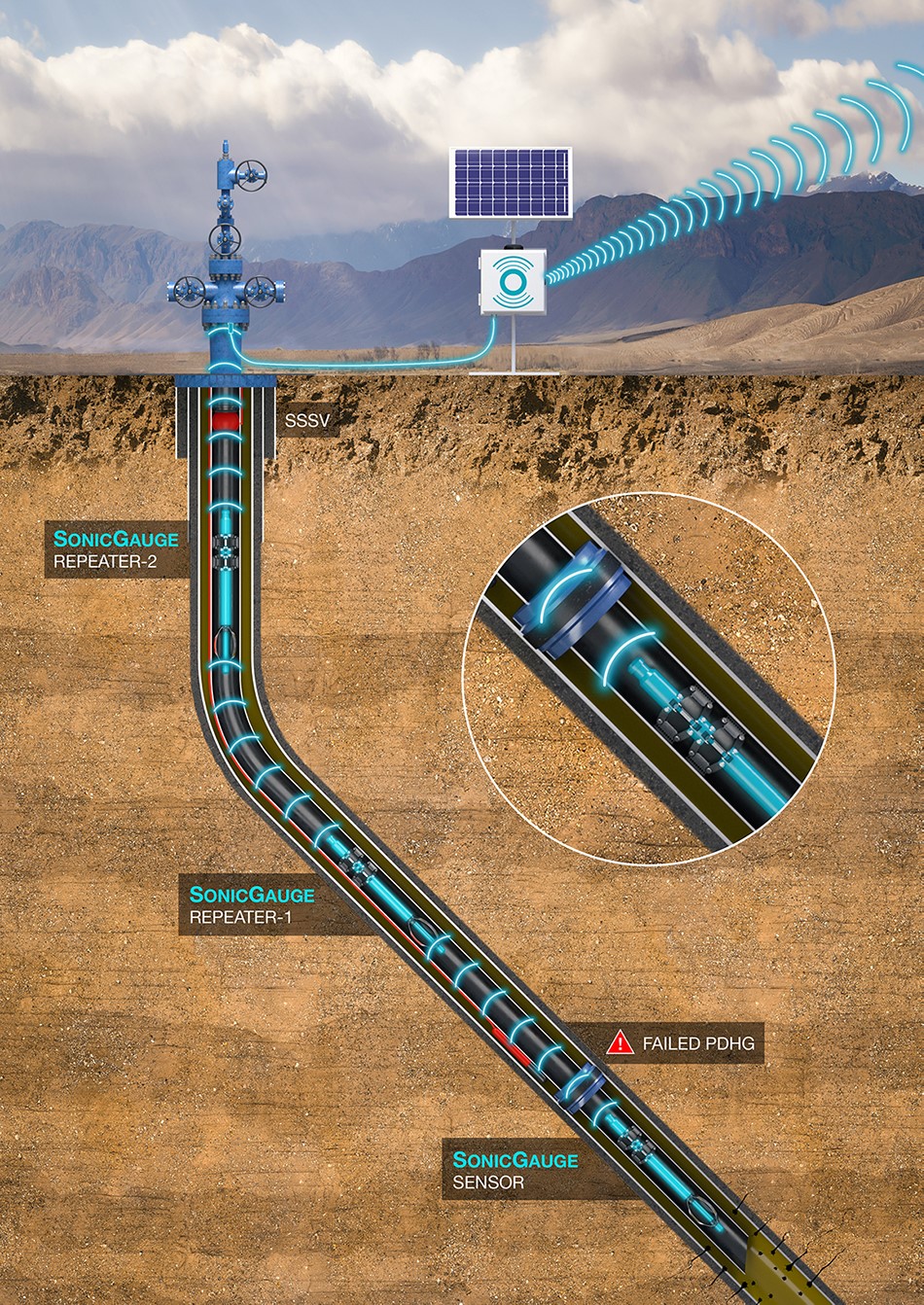

The SonicGauge provides simple, real-time data acquisition and reporting as an alternative to cabled permanent downhole gauges and sporadic memory gauge surveys. The acoustic telemetry system enables engineers to conduct real-time reservoir evaluation in underground storage, production, injection and monitoring wells. The technology’s major advantage is that it can be quickly and safely retrofitted via slickline in existing wells with Acoustic Data’s patented Barracuda HEX-Hanger, a high expansion gauge hanger system.

“Our customers are searching for ways to reduce the cost of installation, to minimize personnel at wellsite and to reduce operational risk—this solution achieves all of this whilst providing immediate OPEX savings. Furthermore, the technology itself provides enhanced reliability over the lifetime of the well. We have deployed this technology more than 100 times around the globe and are sharing that knowledge and expertise to help clients navigate this challenging time,” Norgate added.

Recommended Reading

CERAWeek: NextEra CEO: Growing Power Demand Opportunity for Renewables

2024-03-19 - Natural gas still has a role to play, according to NextEra Energy CEO John Ketchum.

Avangrid Begins Construction on its First California Solar Farm

2024-04-10 - Avangrid’s Camino Solar project will generate 57 megawatts of power, the equivalent of the power needs of about 14,000 U.S. homes.

Dominion Energy Grows Virginia Solar Energy Portfolio

2024-04-02 - Dominion Energy will own or acquire four Virginia solar projects, which have a total capacity of 329 megawatts, the company says.

Could Concentrated Solar Power Be an Energy Storage Gamechanger?

2024-03-27 - Vast Energy CEO Craig Wood shares insight on concentrated solar power and its role in energy storage and green fuels.

RWE Boosts US Battery Storage with Three Projects

2024-02-14 - The three projects—two in Texas and one in Arizona—will lift RWE’s total U.S. battery storage capacity to about 512 megawatts.