A major operator was working to develop multiple wells in the Delaware Basin running a conventional Class H tail slurry at 15.6 ppg. The slurry was reaching 500 psi in 10-13 hours, causing a 2-3 hour wait per intermediate casing job prior to shoe drill-out. At a spread rate of $3,200 per hour, the time spent waiting on cement was adding up quickly.

The operator realized they needed to achieve compressive strength faster to optimize efficiency on each well. However, since conventional strength-enhancing additives can result in high slurry viscosity due to small particle size and increased surface area, the extra step of calculating and adding accelerators at the well site would not solve the problem.

Achieving compressive strength up to 3 hours sooner

The engineering team at Nine Energy Service answered this challenge by innovating a new line of cement designed to consistently reach 500 psi in less than the required regulatory wait time of 8 hours.

Called Rapid Set 1, the mixture combines cementitious materials and specialty additives to achieve adequate thickening and fluid properties for an intermediate tail slurry within the minimum wait time.

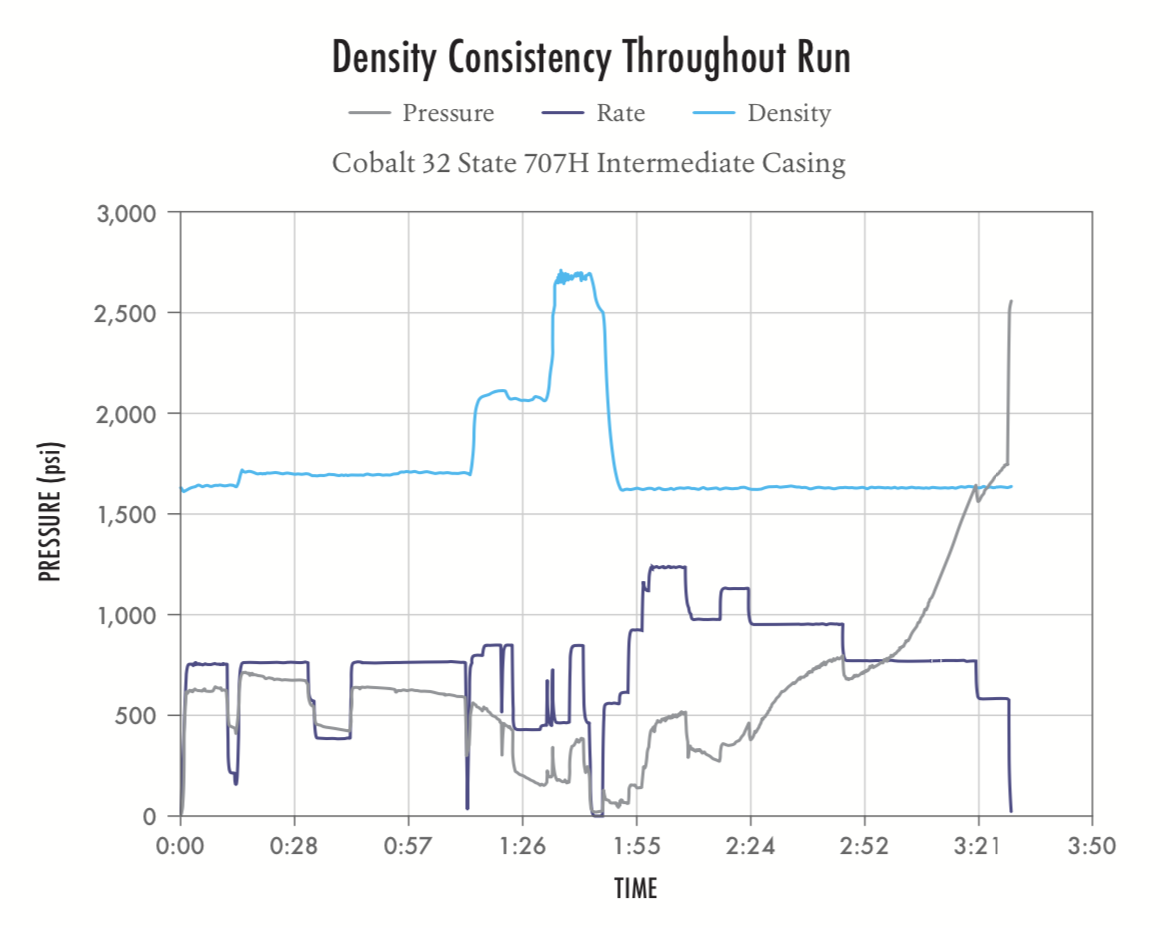

Designed for easy mixing on location, operators can combine and pump these slurries at 4-6 bbl/min or faster if needed. The first slurry was tested and run at a density of 15.6 ppg, which consistently reached 500 psi in under 6 hours after a dynamic conditioning time equal to the placement time (usually 2 hours).

A Micro-Motion densometer, radioactive densometer and pressurized mud scales help to maintain and confirm density throughout the process as psi levels increase. This uniform consistency allowed the operator to achieve successful isolations and helped protect against short- and long-term failures.

Other operators have run Rapid Set 1 at densities of 13.5-14.2 ppg for formations requiring a lighter-weight tail slurry and have consistently reached 500 psi in less than 8 hours. In the more than 150 jobs using this formulation since its introduction, operators have saved approximately $8,000 per well by cutting hours from their wait on cement to exceed drill-out time expectations.

To learn more, visit nineenergyservice.com/rapidset1.