Safety management is at the core of the American Petroleum Institute (API) and the industry’s commitment to ensure pipelines are the safest way to transport natural gas and oil. API established a Pipeline Safety Management System (PSMS) for operators so that they can better understand, manage and continuously improve their safety efforts.

Published in 2015 after a substantive effort by industry operators, contractors, the public and government agencies, API Recommended Practice (RP) 1173, Pipeline Safety Management Systems, 1st edition, is the first standard to address PSMS requirements for pipeline operators of all sizes. Since 2015, PSMS implementation has been a coordinated effort between liquids pipeline operators, gas distribution, transmission, gathering operators, Canadian companies, and the contractor community. In 2021, approximately 84% of the U.S. pipeline mileage participated in a survey on PSMS progress, showing widespread engagement by the industry in implementing RP 1173.

Among its numerous requirements, RP 1173 recommends that an operator “establish a process for evaluating events external to its operations to identify opportunities to learn from those events.” Put simply, to conform with RP 1173 requirements, operators must establish a process to evaluate not only events they have experienced, but also ones from other companies to improve their processes and enhance safety. This information sharing can be invaluable, as other operators can review and similarly, take action to prevent a similar occurrence.

“The industry should be learning from one another so that we continue to drive incidents to zero,” said David Murk, API’s director of pipelines. “Sharing ideas and best practices with each other helps raise the level of safety and operating performance across the entire pipeline transportation industry as outlined in the RP 1173 requirements, contributing to the industry’s mission of protecting the public and the environment.”

Learning and sharing has occurred in the pipeline industry for many years. However, API has developed a tool to further sharing: the Pipeline Industry Practical Experience Sharing (PIPES) Portal. PIPES brings together information detailing what companies have learned from an incident and how they changed their operation to prevent a reoccurrence. Due to the sensitivity of some of the learnings, PIPES is restricted to operators only.

In addition, API and the PSMS Industry Team—which is not limited to API members—help facilitate sharing of external events and learnings through the API Pipeline Conference, Quarterly Virtual Webinars, International Pipeline Conference, Pipeline Information Exchange (PIX), and other avenues.

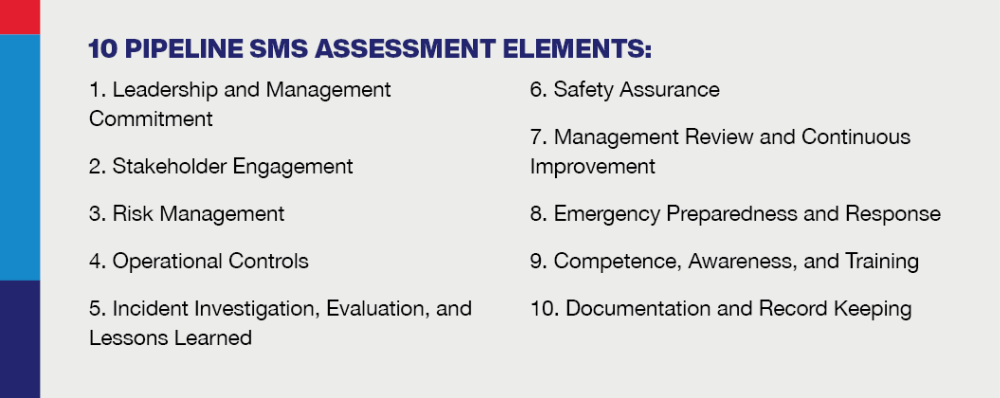

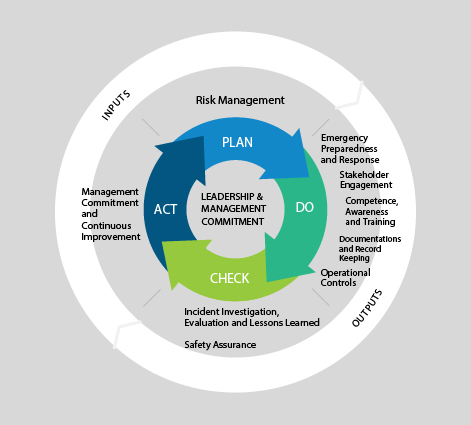

A key part of PSMS is managing key performance indicators and the Plan-Do-Check-Act cycle to enable continuous safety performance improvement for the 10 PSMS elements. This core principle in PSMS requires operators to determine the steps needed to be taken, complete these, periodically review and if necessary, enact any changes or improvements. Ultimately, this requirement drives the industry towards its zero-incident goal by ensuring that the various components of the safety management system are regularly reviewed and continually evolving.

“One of the great things about management systems is that they continually remind us of what is needed to sustain improvement toward our industry’s vison of zero incidents,” said Cindy Graham, the director of Safety and Reliability Governance at Enbridge and chair of the PSMS Industry Team. “For us, the Check and Act components of the Plan-Do-Check-Act process include learning from internal and external incidents. While we have maintained internal incident learning processes for many years, we have in the last few years put in place formal external incident learning processes that leverage our participation in various industry events. These processes provide important information we use to assess and potentially improve our safety defenses.”

Incorporating external learnings is just one of the many requirements of RP 1173. As part of industry’s implementation efforts to help operators share good practices, API, in collaboration with industry partners, developed the Pipeline SMS Assessment Program. API Pipeline SMS Third-Party Assessments are designed to evaluate an operator’s PSMS implementation, share industry good practices and exchange real-time benchmarking information to drive improvements in safety and pipeline safety performance for operators. This assessment includes an evaluation of how operators incorporate external learnings.

Since launching in 2020, the Pipeline SMS Assessment Program has conducted 10 assessments covering a diverse group of pipeline operators from very small steam utility operators to large liquids operators across North America. As a result of the assessments, the Industry Team is analyzing data to evaluate what specific areas, like incorporating external learnings, the industry should focus on to provide more resources to operators and contractors.

To get more involved and to start implementing PSMS, API encourages operators to attend industry events that are open to all to participate, including the API Pipeline Conference in May and the International Pipeline Conference in September. PSMS is a focused topic during these discussions, as it impacts every aspect of pipeline operations. For more information on PSMS or the Pipeline SMS Assessment Program, please visit API.org or email PipelineSMS@api.org.