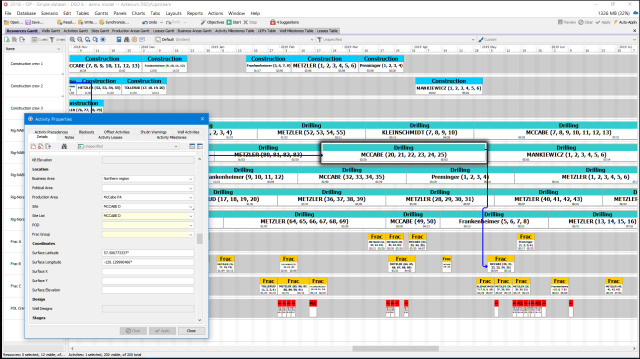

Pictured is a resource-based Gantt chart view of a drilling program schedule where any type of activity and any type of resource may be scheduled. (Source: Actenum)

Today, operators are drilling more wells, faster than ever before. With high operational costs and sometimes scarce resources, rigs and other important equipment need to be properly allocated in the drilling program schedule to maximize efficiency and equipment utilization and minimize downtime.

But while more and more operators are digitizing their operations and becoming smarter about data analytics, they also need to consider the advantages of selecting scheduling software that properly addresses the needs of a drilling program: resource contracts and blackout periods, program milestones, cycle time targets, lease obligations, accurate materials, cost, and production forecasting, and effective collaboration among all team members all have a major impact on business goals and overall program risk.

The challenges of drilling scheduling

Creating and managing schedules for upstream assets is a complex and challenging task that carries with it substantial economic impact on the company. After all, it addresses the critical well delivery value chain that stretches from acquisition of land, through all of the operations required to deliver wells, to production of hydrocarbons from those wells. In the past, drilling scheduling was often done using spreadsheets or other unsophisticated general-purpose project management software tools. But drilling scheduling complexity has grown beyond what can be set up and maintained this way. The challenges of getting equipment to the right place at the right time, with the right people, across a number of pads spread over multiple geographic areas are of paramount importance but are just the start. Efficient well delivery requires many additional aspects of drilling operations to be effectively addressed.

Integrated scheduling

In a true factory drilling process, well delivery is done in an integrated manner. Generally, for example, construction, drilling, frac, facility/pipeline and tie-in activities are focused around each well according to a “just in time” approach, so that they start and finish at the appropriate time, with the most appropriate resources. Pad construction should complete shortly before spud date, and frac activities should start as soon as is practical after a well has been drilled. Also, the right facilities and gathering network components have to be in place before a well can be tied into production.

In order to run integrated operations, a single integrated schedule is required, managed with a single software tool. All resources, activities, and constraints have to be available and visible in the schedule for it to be truly effective and provide value. Using one software tool to schedule drilling, and another to schedule frac jobs, for example, can lead to poor coordination and costly operational problems.[1]

Effective collaboration

With so many moving parts in a drilling program, lack of visibility into all operations in an integrated manner can add to complexity. Take for example, an operator in a shale play conducting hydraulic fracturing. The fracking must be scheduled with the right crews, based on a number of constraints, including the equipment in place, lease obligations, project timing, and other considerations. The operator would need to be clear on the scheduled milestones and responsibilities and know important factors such as when should the permit arrive and who is looking after the permit? They would also have to be aware of known blackout dates for region-specific events, such as Sage GrouseNesting Season or Canadian Freeze Up periods, in which no drilling projects can take place. Disruptions from unplanned events, such as equipment breakdowns, weather compound the problem. Circumstances change because of planned and unplanned events, and rescheduling must be done right in order to keep the operations moving forward.

Furthermore, without clear visibility into key metrics as the schedule is changed, how will the operator know the impact on goals such as costs and production when moving equipment, removing rigs, adding crews, and making other resource decisions? Or, if the schedule is still aligned with key business goals? The finite number of rigs available and differences in rigs, such as spudder vs. big rigs, also makes scheduling more complex. Once a well is in production, scheduling remains key to efficiency. Managing maintenance requirements such as emptying battery tanks or injecting water back into a well must be scheduled accurately and made available to all stakeholders. From planning to production, scheduling is critical to efficiency.

The Value of a Robust Fit-for-Purpose Scheduling Tool

Operators need a solution that enables them to balance multiple constraints or establish highest priority, such as cost per period or DUCs as well as the ability to set and track key drilling metrics such as “Resources Days Idle”. A robust scheduling tool will provide visibility of the schedule by team or business area and enable what-if analysis to generate scenarios and identify the optimal alternative. It will improve the governmental permitting process by knowing exactly when and where paperwork must be submitted. And it will have the ability to be optimized around financial and production constraints while supporting forecasting.

With a robust scheduling tool, senior management, scheduling, drilling and completions as well as procurement will benefit from a single source view of operations that enables everyone to understand the allocation and use of major resources and as a result, improve cycle time. It will also help operators avoid well interference by making use of offset well data to show if there are offset well violations hidden in the schedule which can cause significant operational disruptions and have a negative impact on the drilling budget. By ensuring that schedules are aligned with business objectives, the tool will improve profit and cost tracking.

Configuration is Critical

Critical to scheduling success is a schedule tool that is completely configurable with user-defined activities to meet organization-specific requirements and address all operational and business constraints found in drilling programs. Amongst others, the tool should be able to set contingent tasks, such as construction, drilling, fracing, and POL and provide verification of what resources are compatible with an activity. For example, what type of rig may be used on a particular well, or in a specific area. With the well up and running, the tool should provide an effective means for scheduling maintenance activities to avoid interruptions in operations and ensure equipment continues to work reliably. By performing maintenance too early, operators are burdened with high maintenance costs. When done too late, it can lead to equipment failure and a stop in production.

To enhance operational scheduling, the ideal scheduling tool would provide support regarding logistical challenges and region-specific constraints, including environmental stipulations and blackout periods on any resource, well, or area. Moreover, because every organization’s workflow and business process is different, it will need to be a flexible application with an open architecture for ease of adaptation and integration. One which allows for the ability to import data from multiple sources, such as well production or ERP cost data and can export data to other software.

Architecture Matters

Better decision-making happens when teams have easy access to the metrics that matter to them. With a tool that is designed to organize and isolate schedules around business teams, everyone involved in the operations has visibility into the daily activities that impact his or her particular role within the project.

A scheduling tool providing web-based visibility via a browser makes all critical information accessible from a desktop, tablet, or smart phone. It significantly improves efficiency, collaboration and mobility while providing the latest schedule information anywhere, any time. In turn, this shortens cycle times, reduces risk and helps achieve predictable and reliable production. With configurable scheduling logic, ongoing schedule management is also simplified.

For example, by allowing a user to define the activity types, link them in the correct order and define the time constraints between them, it is easy for the user to insert a new activity into the schedule in one easy step. Gaining timely insights into the efficiency of well delivery operations that are very difficult to obtain by more traditional methods. Using scheduling software ensures operators benefit from flexible reporting via a wide variety of formats that can include Excel, PDF files, Gantt, tabular and graphics.

The importance of “what-if?”

Reducing risk by looking at “What-ifs” is a value-added element in the ideal scheduling tool. By having a sandbox to run scenarios such as running production levels against operating expenses before committing to a schedule, operators have the ability to ask key questions and get answers that determine the best path forward such as: What would the impact be if an extra rig were added? What will the impact be on productivity if we decrease costs by 20%?

Gantt charts also assist in this area. Using Gantt charts, operators have clear visibility into how long a project should take, the resources needed, and the order in which the tasks should be completed. With at a glance visibility, operators can minimize any gaps in the schedule, while also ensuring maximum utilization of resources. Conducting What- if scenarios all provide better understanding of the flexibility or crash potential of various points in the critical path of the rig or production schedule. And as a result, provide the information needed to determine the right action to take.

Conclusion

Today, oil and gas companies are doing the same amount of work they did a decade ago, but with fewer people. The volumes of data available are greater than ever before and tasks have become more complicated. As employees and managers adapt to increasingly complex processes and business decisions, fit-for-purpose tools are required to meet this new reality. In the growing digital oilfield, improved software integration translates into better communication with all areas within the business. To be truly effective, any scheduling software solution must have the flexibility to be deployed in a variety of IT environments. And, it must offer the What-if analysis necessary for optimizing business practices and forecasting development cost and production.

The Actenum DSO/Upstream is a powerful, fit-for-purpose scheduling and optimization software tool that incorporates these requirements to drive significant value for operators. Running on either a localized server or in the cloud on a preferred provider platform, DSO/Upstream allows for flexibility among both the underlying deployment and overall configuration of the tool. The tool provides schedule scenarios to make effective decisions that are key to the success of a drilling program. As a result, it enables operators to improve well delivery efficiency, optimize resource use, and meet cost and production goals.

Click here to see the software in action!

Learn more about Actenum DSO/Upstream.