Noven IoT system is an intelligent well, asset monitoring platform designed for small to mid-size Independents, mature fields operators, unconventional oil and gas producers. System includes battery operated wireless sensors and edge gateway capable of performing wellsite diagnostic.

Noven IoT system is capable of learning from multi-sensor data using ML/AI algorithms at edge device. It provides actionable insights about the health of the well. These unique diagnostics are not available during pumpers’ gaugers’ visit to wellsite. An intelligent system for monitoring and remote diagnostics of oil and gas wells operate with Sucker Rod Pumping. A system for surveillance and remote diagnostics of Artificial Lift operated oil and gas wells using IoT and Machine Learning technology.

Early field case studies demonstrated that Noven IoT System can contribute reducing the operating cost, improve production, eliminate losses due to HSE incidents

Why Monitoring?

Monitoring production data is nothing new for operators, but it’s only been something the supermajors and major companies could afford to do…and even then, they had to pick and choose, only able to monitor maybe 60% to 70% of their wells. Addressing this problem has never been more important than it is today. Weak cash flows and uncertain cost inflation in new projects have led to a change in the business objective of many producers from chasing growth in greenfield projects to optimizing production from existing fields without spending much. There is an increasing demand for affordable technologies.

Noven IoT System is a step forward for providing new production optimization tools available at well site to achieve the digital transformation in onshore oil and gas business. Unique capability of well diagnostic at the edge opens new opportunities from artificial lift to well optimization. The goal is to improve overall efficiency by reducing failures, anticipate deteriorating operating performance by timely introducing mitigation options. As a first application we have selected the underprivileged the sucker rod pumping wells and developed diagnostic capabilities for these well.

System Details

Noven IoT system designed and hardware manufactured in USA. This gave us an opportunity easily customize our system for addressing the needs of diverse customer base.

Hardware

- Proprietary wireless sensors:

- Clamped on Polished Rod Load Cell

- Inclinometer

- Pressure Gauges, Casing and Tubing

- Tank level sensor

- Gateway, capable of performing machine learning

- Communicating via LTE – M1 and Satellite link for Gateway to Cloud connectivity

- Power supply

Software

- Creating surface dynamometer card and performing remote pump, well diagnostics using proprietary AI/ML algorithms.

- Role based User Interfaces: Pumper APP, Engineers APP using Apple iOS and web-based analysis

- Cloud Data Management system

Sucker Rod Pumping Well Surveillance

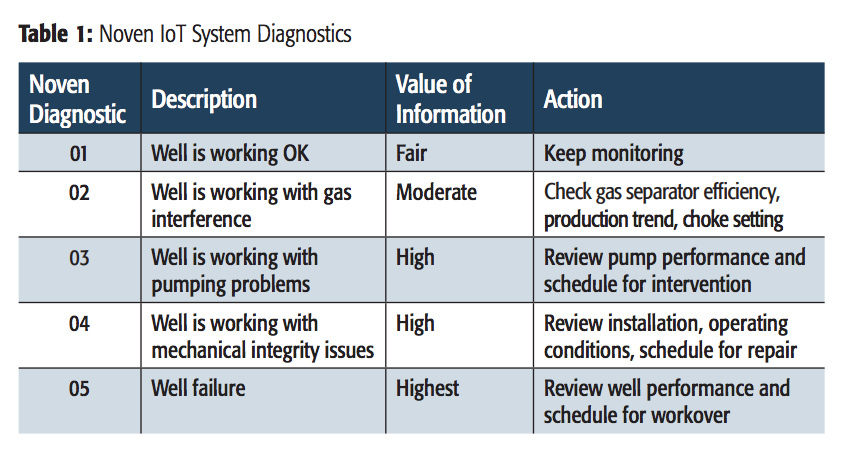

There is a trend of failure frequency decrease among the companies adapted remote well monitoring systems. Pump failure frequency is the largest compared with those of sucker rod and tubing for all the sucker rod pumping wells. We have analyzed over 500 well data and short-listed diagnostic messages under five categories (see Table 1) and automated the process. System captures sensors data and generates AI/ML driven diagnostics on pump operating efficiency and failures.

Case Studies

Noven IoT System testing is ongoing at seven different fields with five operating companies in Texas. These wells are unique in a sense of geometry, depth, pump size and production volumes. Data captured from sensors evaluated in two levels; transient and, time-lapsed analysis. Value of two-level diagnostics illustrated for dynamometer and pressure measurements. During last couple months system delivered below high value diagnostics.

- High Gas Interference

- Multiple tubing failures

- Plugged pump barrel

- Fluid pounding

- Separator dump valve failure

- Deep parted rod

- Flow assurance issue due to paraffin buildup

- Completion change due to mechanical integrity, sanding failures

- Leaking production choke

- Blockage of flow line due to debris, sanding

- Intermittent production due to lack of supply gas, slug flow

- Temporary pump-off conditions

- Transient well tests; interference, build-up and drawdown

Operators took action based on our unique diagnostics, which were not obtainable with pumper visits.

Benefits

- Bluetooth Low Energy radio communication for sensors

- Non-intrusive, rapid deployment capability (<30 min)

- Pump diagnostics using surface dynamometer cards generated online at the well site

- Casing and tubing pressure transients and trend analysis

- Focus on wells that require immediate attention

- Reduce non-productive time, production losses

- Reduce number of visits to well sites by using Alerts and Status of Wells

- Monitor, reduce, detect spills from tank batteries with Alerts

- Reduce wellsite visits which also improves safety

- Continuously monitor pressures and have the ability to set up thresholds to detect anomalies

- Remote device management

- State awareness of the assets near real time

- Minimize downtime, unplanned shutdowns

- Early intervention capability for crisis management

Typical Engagement

Solution as a Service businesses pay a set monthly fee for the entire solution. Instead of paying multiple vendors or trying to manage part of the solution in-house, businesses only have one bill to pay. It includes:

Install the System. Sensors are tuned for individual application and come configured. Software is already pre-loaded and ready to manage operation of production systems. All communications, controls, and data from sensors to the back-office ops center are securely managed.

Configure dashboards and alerts. Our visualization framework allows monitoring and controls any time anywhere. Only the relevant information is sent to the users, saving data clutter and bandwidth costs.

Operations support. We install, maintain and operate including instrumentation of assets, infrastructure setup, and software updates.

We are coming into an age where processing power, edge technology and cloud-based solutions dominate everyday life. Bringing these different facets of advanced technology together and seeing how we can help customers solve complex problems, drive greater efficiency, and drive productivity. We developed a robust, highly scalable end to end, low cost IoT platform. Our System will be for all, from striper well operators to independents, super majors, national resource holders.

For more information, visit www.noven.io.