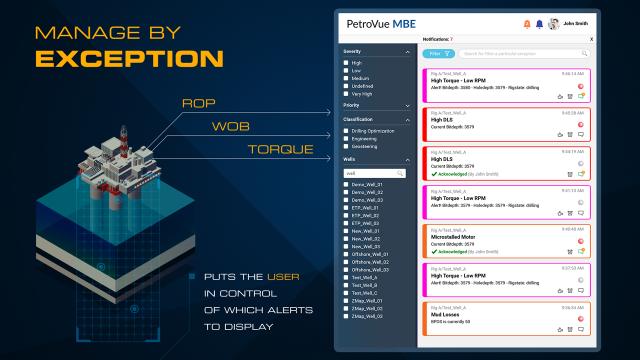

The MBE Notification Screen shows the alert priority and helps the user work smarter.

Throughout the process of drilling a well, issues can arise that can slow down, or even halt operations. Monitoring the various workflow activities at each pod is key to maintaining operations. However, as personnel are only physically able to monitor a few wells with different workflows at the same time, monitoring each pod is extremely challenging, requiring companies to reduce the number of wells it could monitor.

Additionally, calculations during drilling are typically done manually using data points from visualization software and plugging that information into Excel sheets to determine if an anomaly exists or not – within a specific point in time. While a traditional procedure for the industry, this method of taking a snapshot every few minutes while drilling does not provide the complete, accurate picture of what is happening at every moment downhole.

These are key challenges facing oil and gas companies today. To solve these multiple challenges, an E&P supermajor with assets worldwide turned to the MBE system (Manage by Exception) from Petrolink.

Delivering Multiple Advantages

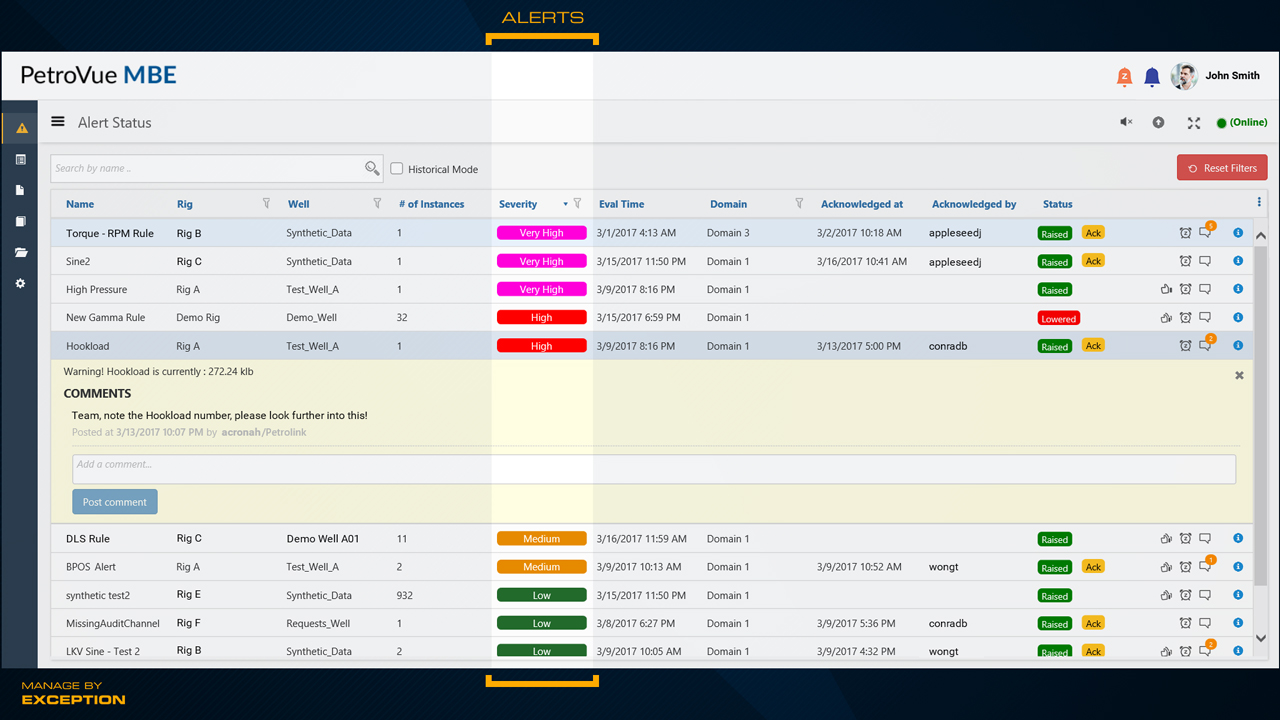

The MBE platform provides the supermajor with multiple advantages around the globe. First, it allows them to monitor multiple rigs in real time remotely, freeing up the personnel required for monitoring while increasing accuracy by providing continuous data. This advanced system monitors multiple workflows across a fleet of rigs simultaneously, including Displacement and Analysis While Drilling, Well Drilling and more. More importantly, MBE identifies an initial issue before it becomes a problem. For example, the system’s Torque and Drag Modeling and Analytics tool alerted the company of poor hole cleaning, allowing them to correct the event in real-time while ensuring the integrity of their equipment.

Ease of use is another key advantage of the system for the supermajor. With so much data available today, paying attention to each screen and which alerts are most important can be unmanageable. But the MBE system constantly monitors the condition of the rule and then raises only the resulting priority alert to exactly the right person, relieving alert overload and ensuring people are paying attention to only what’s really important.

In addition to recording an acknowledgement, comments may be added to make note of specific conditions and to advise the global team.

The Results

MBE has delivered significant results in terms of cost savings, time-savings, and problem avoidance. Since the system has been implemented across all the supermajor’s onshore and offshore wells, numerous well control events have been captured, representing a significant cost-savings. These were anomalies that the supermajor wouldn’t have been able to identify previously with manual oversight. In addition, due to its ability to monitor multiple wells remotely, MBE has enabled the supermajor to benefit from a manpower savings as well. Furthermore, the system has the capability to navigate between different onshore and offshore rigs and their various workflows, without having to set up a specific set of alarms for specific wells, making it an extremely flexible solution. Today, the supermajor also uses MBE for Process Safety workflows as well as Risk Assessment.

Typically, when it comes to adopting new technology, there can often be resistance. However, for this supermajor, MBE became a must-have system very quickly. With its continuous monitoring, ability to prioritize alerts and its easy adoptability, MBE is now found across the company’s entire fleet.