Oil and gas field measurement applications are arriving on the scene just as the industry is in the midst of substantial changes in operating strategies. In response to the prevailing business climate, producers are seeking to increase operating efficiencies and optimize producing assets.

This is particularly the case in unconventional resource plays with multiple-well pads. Horizontal wells completed with multistage fracturing in unconventional reservoirs typically experience 50-80 percent production declines within the first year. In addition, recovery rates in these plays are reported to range between only 1 and 9 percent. So, although many tight oil and shale gas wells were brought on line only recently, the rapid decline rates characteristic of unconventional formations are a considerable challenge to returns on capital investments.

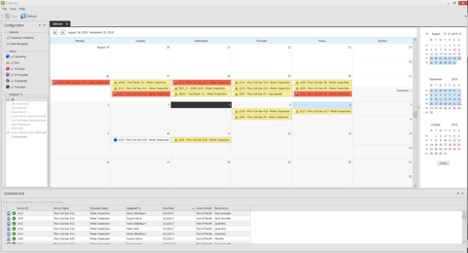

In order to optimize production, enhance production economics, and ultimately improve recovery rates, it is necessary to maintain production data integrity. Without it, decision-making to achieve optimal well performance can be slowed down, or even flawed. Achieving production data accuracy and accountability starts in the field with measurement applications that automate the management and scheduling of meter inspections, sampling, and calibration events.

The key capabilities of these automated field measurement applications provide a powerful and comprehensive solution that companies can put to work rapidly to optimize production and help improve bottom-line business performance. Users benefit from rapid payback in terms of compliance, enhanced production, increased asset efficiency, and lower operating costs.

These applications process the considerable data that is provided by production measurement equipment at remote well sites and present them to management in an effective and timely manner. They can pull together information from a broad array of sources with widely varying formats and time bases. For a particular meter, the application checks calibration and verification reports from a technician, tracks hourly data from a flow computer, and is able to coordinate that with a gas analysis report that just arrived from a laboratory.

The applications further provide editing, reporting and data export functionality that ensures compliance with audits, industry regulations and standard operating procedures. Data validations and system balancing flag data anomalies, account for missing data, expose sources of unaccounted-for inventory, and maximize the integrity of the production information. The complete visibility of information gives production teams the confidence to trust their well performance and trend data.

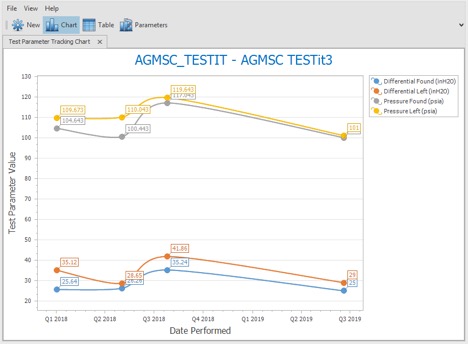

Want to hear more about how companies are improving their production data integrity with field measurement applications? Join us in our live expert panel to hear how Quorum Software’s TESTit provides an automated way to always have the most accurate and recent testing and calibration data at your fingertips, driving smarter operational decision-making.