The industry downturn has spurred exploration and production companies to find new ways to reduce cost and increase efficiency. The legacy approaches used for scheduling and analyzing drilling programs are a key place to look for opportunities to improve operational processes and reduce cost, since drilling represents the majority of the dollars expended in monetizing reserves and is in the critical path to first-oil.

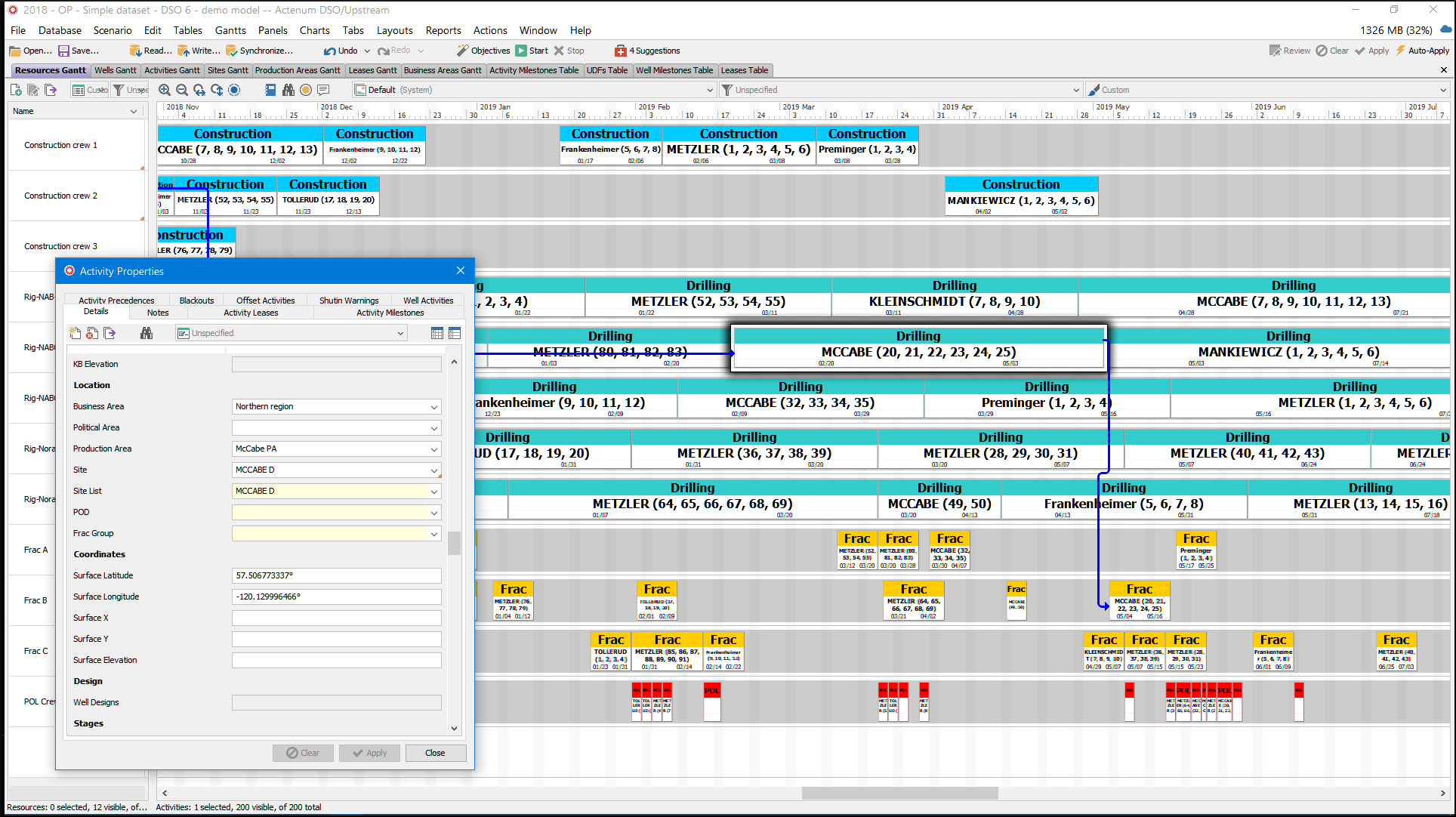

Historically, many operators relied on an incohesive mix of application software to manage and analyze drilling schedules, including spreadsheets and general-purpose project management tools, together with extensive and tedious manual calculations. Recently, a large independent E&P company developing assets in the Permian Basin launched a two-fold investigation. First, they searched for a single tool to effectively schedule and manage drilling program activities and associated resources in an integrated manner. Simultaneously, they wanted to be able to rapidly analyze the potential impact of scheduling decisions on key metrics, including drilling cost, resource utilization, forecast production output, and cycle times. After an extensive evaluation of several products, the company selected Actenum DSO/Upstream. It schedules and optimizes all activities necessary to bring a well on line, from pad construction to drilling, fracturing, tie-ins, and ongoing maintenance after first oil. Actenum DSO/Upstream also equips users with the ability to gain valuable insights into drilling program metrics, and the capacity to transform the scheduling process, leading to efficiency gains in operations.

The challenge

Until recently, the E&P company managed their drilling program schedule using separate tools. This introduced complications and inefficiencies, including a disconnect in communication and collaboration across schedules and among cross-functional teams. The schedule became increasingly difficult to manage because complex factors such as resource constraints had to be applied manually, often resulting in extended cycle times, with gaps in the schedule where rigs and other resources were idle. Project milestones were also often missed. The lack of an integrated scheduling tool provided limited visibility over the complete schedule in real-time, and almost no insight into key metrics. The company needed a proactive scheduling tool to manipulate and analyze the schedule instead of being in a continual reactive mode. Feature requirements for their ideal solution included:

- Drag and drop Gantt charts

- Custom views of the schedule by discipline

- Views of milestone status and their impact on the schedule

- Accommodation of various project types

- View of capital spend and other key metrics over time

- Robust data integration with third-party applications

The solution

Actenum DSO/Upstream was tested in a major asset. Key findings included:

- Actenum DSO/Upstream provides centralized, integrated rig schedule information, with comprehensive data integration capabilities.

- The software is easily configured to suit the needs of different disciplines.

- The drag-and-drop Gantt charts and straightforward user interface fit well with existing work processes, rather than requiring process redesign.

- Actenum DSO/Upstream accommodates all aspects of the scheduling process including activities, resources, constraints, and related data. Optimization may be used to align schedules against prioritized business objectives, ranging from decreasing well cycle times to minimizing cost.

Actenum DSO/Upstream was also able to provide answers rapidly to frequent questions, such as:

- When will drilling be complete for specific pads?

- How can wells be brought online more rapidly?

- Given a fixed number of rigs and wells to be drilled, what is the most appropriate completion schedule to achieve target oil production at minimum cost?

Although the software was evaluated during the industry downturn, the company elected to purchase the Actenum solution as it determined Actenum DSO/Upstream to be essential to reducing costs and optimizing development of their drilling assets.

Actenum DSO/Upstream is used across all assets as the standard tool for scheduling

With a single tool managing the entire integrated schedule, the company increased the efficiency of their scheduling process by bringing wells on line faster, and Actenum DSO/Upstream also increased visibility across well inventories and drilling operations. Insights into metrics informed decisions on the optimum order of wells to be drilled, and where to optimize drilling efficiency and asset utilization. Since the schedule tracked capital expenses (CAPEX) and operating expenses (OPEX) over time, the company was able to plan resources and budgets more accurately than previously. Before the implementation of Actenum DSO/Upstream, the company could only perform limited “what-if?” scenario analysis that required extensive manual calculations. Now, multiple scenarios are created and analyzed in minutes.

If you’d like to see how Actenum DSO can help increase efficiency across your operations, contact us at info@actenum.com.

Ready to see the software in action? Watch this brief demo video.