From deep, prolific formations crinkled beneath its massive thrust sheets to thick coal seams layered below its windswept eastern prairies, Wyoming bears vast quantities of natural gas. And, thanks to a relentless application of technology, operators are recovering ever more of this resource at economic rates. Wyoming's natural gas production hit 1.2 trillion cubic feet (Tcf) in 1998; that was the most produced in the state's history. All indications are that 1999 gas production will continue the upward trend. According to the Wyoming Oil & Gas Conservation Commission, approved oil and gas well drilling permits surged from 1,903 in 1997 to 2,448 in 1998, to more than 5,800 in 1999, with December applications still being processed. Granted, more than 80% of the permits issued in 1999 targeted ultra-shallow coalbed methane reservoirs, mainly in the sizzling Wyodak play in the Powder River Basin. Yet, operators statewide are engaged in gas projects of all stripes as well. The prodigious quantities of gas locked in Wyoming's sandstones, shales, dolomites and coals are succumbing to the focused efforts of companies that are applying the latest technologies. Dogged experiments with everything from fracture stimulations in finicky tight sandstones to openhole completions in low-gas-content coalbed reservoirs are turning once non-commercial plays into valuable corporate assets. At the same time they are enhancing well productivities, operators have also been successfully lowering well costs. No question, the economics of natural gas production in Wyoming today are far better than those endured a decade ago. An easing of the basis differential that has long penalized producers in the region has further helped. As Wyoming's pipeline web has expanded, the greater access to national markets has translated into wider wellhead margins. One company that has hitched its future to Wyoming is Tom Brown Inc. Statewide, Tom Brown operates 445 wells and produces a net 65 million cubic feet equivalent per day. The firm, an aggressive acquirer of acreage, holds 1.8 million net acres in the Rocky Mountain region, the bulk of that in Wyoming. Tom Brown recently relocated its corporate offices to Denver after more than four decades of maintaining its headquarters in Midland, Texas. The move brought management closer to its core Rocky Mountain assets, says president Jim Lightner. The company also staffs three field offices in Wyoming-in Riverton, Rock Springs and Gillette-and it owns a six-rig drilling company that works mainly in the state. Tom Brown will run an average of four rigs in Wyoming this year, says Lightner. "Company-wide, we are increasing our capital budget by 50% to 60% over last year's levels, and much of that money will be spent in Wyoming. "We are committed to exploration in southwest Wyoming," he says. "Wyoming has great resources in its deep basins. However, exploring for these unconventional resources is very expensive and the technology to identify sweet spots is evolving rapidly. We're committed to using new technology, in drilling, completions and in exploration, to unlock these basin-center resources, and we have positioned our acreage to make sure that we participate in the new discoveries." Although Wyoming-like most all of the United States-is considered a mature area, its deep basins are largely unexplored, says Lightner. "If we plot the wells that penetrate below 10,000 feet, both the Wind River and the Greater Green River basins are still frontiers." Indeed, work in the lightly drilled Wind River Basin has been yielding tremendous results of late. In 1991, the Wind River produced just 170 million cubic feet of gas per day; in 1998, Fremont and Natrona counties produced an average of 408 million cubic feet per day. Those numbers should continue to grow strongly, thanks to ambitious programs such as Burlington Resources' Madden Field development. The largest field in the Wind River Basin, Madden produced 563 billion cubic feet (Bcf) of gas and 640,000 barrels of oil between its discovery in 1968 and the end of 1998. Composed of a series of reservoirs draped over an immense anticlinal feature, Madden lies on the northern edge of the basin near the Owl Creek Thrust. "Our activity in Wyoming is centered in Madden Field, a federal unit that covers 70,000 gross acres," says Barry Winstead, Midland-based vice president of Burlington's Midcontinent division. Madden has a split personality, hosting two separate types of production. Four "shallow" sandstone intervals flow sweet, pipeline-quality gas from depths between 5,500 and 20,000 feet, says Jack Morrow, Rocky Mountain area manager. The company produces 110 million cubic feet per day gross from about 70 wells completed in Tertiary Lower Fort Union and Cretaceous Lance, Mesaverde and Cody reservoirs. Fundamentally different is the Madison, found at depths between 24,000 and 25,000 feet. The Mississippian dolomite reservoir contains 12% H2S, 19% CO2 and 69% natural gas; the drilling environment is hostile and terribly corrosive. Additionally, bottomhole temperatures hover in the neighborhood of 440 degrees F, and widely different pressure regimes occur between the surface and the normally pressured Madison. Prior to Burlington's acquisition of Madden in 1997 (the assets were part of its merger with Louisiana Land & Exploration), developing Madison reserves had been an obtuse process. The first two of the deep and difficult wells had sat shut in for years, due to the lack of gas processing facilities; a third well had just been completed. When Burlington arrived, Madden had three producing Madison wells capable of producing 45 million cubic feet per day apiece, but total processing capacity of just 50 million per day. Recoverable reserves were estimated at 2 Tcf. Burlington believed that the Madison was capable of much more. The company immediately upgraded the processing plant, bumping capacity to 65 million cubic feet per day. This past July, it completed a twin to the processing plant, adding additional capacity of 65 million a day. Madden's gross production from three Madison wells now stands at 135 million per day; sales gas sent to the pipeline from the Lost Cabin processing plant totals about 90 million a day. "We have a project ongoing for a third expansion of the gas plant, scheduled to be completed in 2002," says Winstead. "That will give us additional capacity of 180 million, bringing our total inlet capacity to 315 million cubic feet per day." At the beginning of 1999, Burlington also spudded a fourth deep well, the Bighorn #5-6. The company and its partners-W.A. Moncrief Jr. and North Central Oil Corp.-put Parker Drilling's massive Rig 201 under a three-year contract to help it develop Madden's deep potential. Tulsa-based Unit Drilling Co. purchased Parker's fleet of 13 domestic rigs last September, including the big rig. "Rig 201 is the only operating rig of its size in the United States," notes John Nikkel, president. "Depending on the casing strings, it is capable of drilling to 40,000 feet. It's a 4,000-horsepower rig with a 2-million-pound mast." The #5-6 well reached total depth of 25,190 feet in November 1999. The test was a rousing success, encountering 196 feet of net pay in the Madison and extending the limits of the field an additional 210 feet downdip. At press time, the company was testing the massive well, with first production expected this summer. Of note, Burlington drilled the Bighorn #5-6 in a record 300 days, almost half the time spent drilling the previous well. The company also saved $10 million over the cost of prior wells, dropping the price of a Madison producer-including completion, facilities and tie-in to the plant-to around $30 million. "We drilled the #5-6 quickly and we drilled it for substantially less money than the previous wells," Winstead says. Money and time were saved by bypassing two casing seats that had been used in previous wells; by eliminating a tie-back string; and by running a tapered string through the troublesome overpressured Frontier interval and reverse cementing it. Different alloys used for the liner and production tubing added to the savings. The company also employed oil-based mud, fixed-cutter bits and downhole motors and turbines in new ways. "Our design team and our rig supervisors really pushed the envelope to find ways to drill this well differently," says Winstead. Burlington and partners are now drilling the Bighorn #6-27, a test that will attempt to establish production an additional 600 feet downdip of the #5-6. "We have not yet determined the downdip limit of the field," he says. Results of that test will determine where the big rig goes next; regardless of the outcome of the #6-27, Morrow notes that the company has several other Madison locations on its books. "We have no doubt that we can fill all 315 million cubic feet of plant capacity," he says. Burlington also is expanding production in the shallow, sweet-gas formations. The typical depth to the Fort Union, the main productive horizon, is about 8,500 feet. For the last several years, Burlington has been budgeting about 10 Lower Fort Union wells annually. "We are infill drilling and extension drilling to the north, east and west of the field," says Morrow. "We have more locations left to drill, and we intend to continue to exploit the shallow horizons." Furthermore, Burlington and partner Enron Capital & Trade plan to build a 24-inch, 124-mile pipeline to tie Madden Field into a point near Wamsutter, Wyoming, along the Interstate-80 pipeline corridor. Initial capacity will be 275 million cubic feet per day, although with additional compression the line will be capable of moving far greater volumes. Construction will begin this year. "Historically, the take-away capacities from the central Wyoming basins have been constrained. It's a much better picture than it was 10 years ago, but still the lines are crowded when we want to move a lot of gas out of central Wyoming, especially in the winter months. This big line will help alleviate that problem," he says. Just a handful of miles east of Madden lies another major producing Wind River Basin field, this one of a much more recent vintage. Barrett Resources Corp.'s Cave Gulch find ranks as one of the largest recent gas discoveries in the Rockies, containing more than 600 Bcf of reserves in a very small area. (See "Cave Gulch," Oil and Gas Investor, April 1998.) Cave Gulch straddles the Waltman Arch at a point where the regional structural feature is overridden by the Owl Creek Thrust. Denver-based Barrett's first well at Cave Gulch was drilled in 1994 as a subthrust 6,900-foot Lance discovery. That test produced at a steady rate of around 10 million cubic feet per day, and sparked industry interest in the entire area. Since then, Barrett has drilled 35 wells in the shallow horizons ranging between 4,500 and 10,000 feet in depth. "Cave Gulch has grown into one of our three core properties," says Peter Dea, vice chairman and chief executive officer. "It continues to reap more and more rewards for us over the years. Presently, we produce about 104 million cubic feet per day gross and 73 million net from Cave Gulch." The company subsequently developed high-volume deep production in the Frontier, Muddy and Lakota sands as well, drilling eight wells at Cave Gulch that range in capacity from 10- to 45 million cubic feet of gas per day. The deep wells average $8.3 million apiece to drill and complete. Barrett's challenges include drilling through vertically dipping beds in the Owl Creek Thrust, fractured lost circulation intervals and a severely overpressured deep section below 17,000 feet. From Barrett's first deep discovery in 1997 to the most recent 19,550-foot well, Dominic Bazile, drilling and completion manager, has reduced the drilling time from 160 to 100 days. In the 1980s, comparable deep wells averaged drilling times of 450 days. "We have focused on optimizing the design in mud systems, casing and bit selections with each additional well, reducing days and costs," says Bazile. "3-D seismic is essential to interpreting this complex deep structure and guiding the drill bit through complex arrays of faults," adds Dea. Based on its success with the deep Cave Gulch structure and a new 3-D seismic survey, Barrett recently stepped out to drill a 19,550-foot wildcat on the Waltman feature, three miles to the south. "The structures are two separate, mirror-image deep features," says Dea. "Cave Gulch is located on the north side of a high-angle reverse fault, and Waltman Deep lies to the south on the upthrown side of another high-angle reverse fault." Barrett's Bullfrog #5-12 well looks very promising-it came in 900 feet high to an offset well and had gas shows and potential pay identified from well logs in the Frontier, Muddy and Lakota sands. At press time, the company was testing the wildcat. "The First and Third Frontier sands look particularly good," says Dea. If successful, Barrett has identified as many as six offsets to the Bullfrog #5-12. The company has also drilled another rank wildcat in the Waltman Deep area, the Bullfrog #4-14. A 12,375-foot Mesaverde test, this well came in 400 feet high to an offset and recorded gas shows and potential pay on logs. "We potentially have a new-field discovery in the greater Cave Gulch area," says Dea. "We continue to look both deep and shallow throughout the whole region." He notes that a few more deep development locations also exist in Cave Gulch Field proper, and that the company is looking at 20-acre spacing in the shallow zones. Tom Brown Inc. is also heavily involved in the Wind River. The firm holds 800,000 net acres in the basin, including an enviable acreage position leased from two Native American tribes, the Eastern Shoshone and the Northern Arapahoe. "Most of our production and most of our activity has been in the Wind River. Last year, we doubled our production in the basin from 20 million cubic feet of gas equivalent per day to 40 million per day," says Lightner. "In 1999, we drilled 20 wells in the Wind River, and this year we plan on about 38." Tom Brown has been assembling a substantial exploratory portfolio in the basin over the past several years; 2000 will see a number of tests on these projects. "We have quite a few big, deep-basin gas prospects that we are going to test," says Lightner. "These are very large, high-risk targets at depths ranging from 12,000 to 17,000 feet." Another prime Wyoming basin where operators see potential for liberal additions of new gas production is the Greater Green River, an immense portion of southwestern Wyoming that contains the Green River, Washakie and Red Desert sub-basins. The U.S. Geological Survey estimates that the Greater Green River Basin holds total resources of more than 67 Tcf of gas; through 1998 the basin had produced just 7.2 Tcf. Prolific gas production has long been established in the Overthrust Belt, stretching along the basin's western margin, and on the Moxa Arch, a gigantic structural high just east of the thrust sheets. Still, interest in the largely unplumbed depths of the deep basin was faint prior to 1992, when Jonah Field began to be developed in Sublette County. The overpressured Lance Formation, a series of stacked, tight sandstone lenses, is the target of drilling in Jonah. In October 1999, the state reports that production from Jonah topped 259 million cubic feet of gas per day from 147 wells. (For more on the early years, see "Jonah's Tale," Oil and Gas Investor, June 1997.) Jonah covers 25 square miles and has wells capable of producing between 5- and 8 Bcf apiece from average net pay thicknesses of 500 feet. These are long-lived producers exhibiting steep declines the first year, and very gradual declines thereafter. Initially, the field-comprised mainly of federal acreage-was developed on 80-acre spacing. Presently, operators are applying for 40-acre spacing within its core, and the Environmental Assessment for that application is under way. Given the downspacing, estimates are that Jonah could eventually produce at the rate of 400 million cubic feet per day. Ultimate field recoveries currently look to exceed 1.8 Tcf of gas. At first, the field was thought to be a basin-centered gas accumulation. As Jonah developed, however, it became apparent that a structural component was also controlling production. Lateral strike-slip faults bounded the production on its western and southern sides. Ultra Petroleum Corp., like a number of other firms, believes that another Jonah can be found. The Canadian company, which maintains its main office in Denver, focuses all of its efforts on the Lance play in the northern part of the Green River Basin. Its main area of interest is the Pinedale Anticline, a 30-mile-long structure that lies directly east and northeast of Jonah. Ultra owns interests in 21 wells in Jonah Field proper and 20 wells in Pinedale Field. A year ago, Ultra was mired in some serious problems. The company owed money and had lost credibility with its partners, vendors and with the investment community. Chairman and chief executive officer Mike Watford, formerly with Nuevo Energy Co., joined the struggling firm in February 1999 and launched an aggressive turnaround. "We owed $8 million we didn't have, and we decided to sell a half interest in leases we owned on the Pinedale Anticline," says Watford. "At the time, that represented our best undeveloped acreage." Ultra sold 15,700 net acres to both The Anschutz Corp. of Denver and Questar Energy Co. of Salt Lake City; the company received $13.2 million from the transaction. With the proceeds, Ultra paid off its debts, slashed its G&A costs, and funded a $10-million capital program for the latter half of 1999. "We've also reduced our average well costs from $3.5 million to $2.5 million. We're still in the midst of our turnaround, but now we have positive cash flow and earnings. And we have increased our borrowing base at the bank," he says. For 2000, Ultra plans a capital budget of $20.5 million. The company will drill or participate in 18 wells on its acreage, including locations in the Pinedale Anticline area and in Jonah Field, subject to approval of the downspacing order. Ultra believes that structure, and its subsequent enhancement of fracturing, significantly contributes to the relative permeability and porosity in the Lance reservoirs. That's why it is making its play on the Pinedale Anticline, a feature that was formed after the deposition of the Lance beds. Some 30 wells, dating from the 1950s onward, dot the long structure. "Drilling on the anticline has yielded everything from dry holes to 10-Bcf wells," says Stephen Kneller, Denver-based vice president of exploration. "A tremendous amount of 3-D seismic data has been acquired in this area in the last year, and right now we-and the other operators-are studying that data to determine the sweet spots." Indeed, drilling programs are on hold on the anticline until spring. Most of the acreage is federal, and an Environmental Impact Statement is currently in progress. After the Record of Decision is issued, full-scale development of the field can begin. "The Pinedale area contains tremendous gas resources," says Watford. "We believe that two or three more Jonah-size fields can be developed along the anticline. Right now we are in a lull while we interpret the 3-D seismic and wait for the EIS to be completed, but we expect to be very busy by summertime." Another firm hunting for new gas accumulations in the basin is Denver-based Kestrel Energy. Its focus lies further to the south, says Timothy Hoops, president. Kestrel's 20,000-acre Green's Canyon prospect is in Sweetwater County, just west of Rock Springs on White Mountain. The company has amassed another 15,000 acres in the project area. Aspects of Green's Canyon are analogous to Jonah Field, says Hoops. Davis Petroleum drilled two existing wells on the acreage in the late 1970s, but neither was produced. One was abandoned after disappointing completion attempts in the Cretaceous Dakota; the other was never completed despite an initial test of 1.5 million cubic feet per day from the Frontier. "We think we understand the play geologically. The challenge is to apply new drilling and fracturing techniques to recover the reserves," he says. "We've drilled our wells underbalanced, and we plan to frac underbalanced using bauxite as a proppant, versus the sand used previously, and using modern stimulation fluids.." To date, the company has drilled two 15,000-foot-plus wells on its acreage and has acquired a 25-square-mile 3-D survey. The first well cut 26 net feet of sandstone pay in the Second Frontier; the second came in 106 feet high to prognosis and had potential pay in the Second Frontier, Muddy and Dakota zones. Kestrel has also reentered one of the old Davis wells, targeting the Muddy and Frontier. The firm will fracture stimulate all three wells as soon as it completes a flow line into the property. Presently, Kestrel plans a 35-well development program in the area; it will begin drilling again as soon as the mud season ends this spring. "For a small company like ourselves, this could be a company-maker," notes Hoops. Tom Brown Inc. also works the Greater Green River. The company gained a substantial position on the Moxa Arch through a property acquisition in late 1996, says Lightner, and it holds large exploratory acreage spreads in the Washakie and Red Desert basins. "We are well represented throughout the Greater Green River," says Lightner. "We hold 308,000 net acres and we produce about 21 million cubic feet equivalent in the basin." Last year, Tom Brown drilled 7 wells and participated in 200 square miles of new 3-D; this year it plans to drill 19 wells. The tests will be both exploratory and development, he notes. "We will also shoot a large 3-D survey on a new exploratory idea." For all the conventional exploration in sandstones and carbonates, perhaps no Wyoming gas play has yielded results as surprising as those of the Powder River Basin's coalbed methane. The state reports that its coalbed methane production topped 197 million cubic feet per day in October 1999. The gas was flowing from 1,259 wells. More is to come-shut-in wells not yet hooked up numbered another 965. The prospective area includes all that underlain by the Fort Union Wyodak and Big George coals-an expanse of an astounding 5 million acres. While the coal rank and gas content of the Powder River coals are substantially lower than those found in other producing coalbed methane basins, the very thick coal seams (ranging from 60 to 275 feet) and their high permeabilities offset these drawbacks. Estimates of recoverable gas reserves range from 4- to 16 Tcf, putting the play in the league of the San Juan Basin. (For more, see "Coalbed Methane" in the November 1998 issue of Oil and Gas Investor and "A New Power in the Powder" in this issue.) Barrett Resources entered the play in 1997, in a joint venture with fellow Denver firm Western Gas Resources Inc. The companies each hold 50% interests in 926,000 gross acres in the Powder River Basin. "We are convinced that the coalbed play contains significant resources," says Barrett's Dea. "Our production from the Powder River Basin is now 135 million cubic feet per day gross and 50 million net. Barrett and its partner are targeting gross production of 180 million per day by year-end, and rates of 290 million per day by the end of 2001." Barrett plans to devote $40 million to the play this year, drilling almost 800 wells. That's even in the face of an Environmental Impact Statement slated to begin this March. This follows the recently completed Wyodak EIS, which provided for the drilling of 5,800 wells, covering about 3,000 square miles or 2 million acres. The regulatory process is expected to take around 18 months; when complete, the new EIS will provide for an additional 15,000 to 30,000 locations. "In our joint venture, we can drill 800 wells in 2000 and another 800 wells in 2001," says Dea. "Only about half of our acreage is federal, so fortunately we have enough fee and state land to maintain a very aggressive drilling program." Barrett's 2000 program will focus on two objectives. One is development drilling in the Wyodak fairway, an area some 75 miles long by 20 miles wide. Here, a typical well is between 250 and 650 feet deep, and it produces 200,000 cubic feet per day after six to nine months of dewatering. Ultimate recoveries per well are estimated at 400 million cubic feet of gas. "We have drilled about 1,200 wells in the Wyodak fairway, and we have had some exciting encouragement from a step-out pilot that lies about two townships south of the main producing area," he says. About 600 Barrett wells will be devoted to developing acreage in the Wyodak fairway this year; another 100 will be in Wyodak pilot projects. The pilots typically contain 10 to 30 wells on 80-acre spacing. Barrett's other objective is expansion of the Big George play, a stratigraphically younger coal seam that averages about 120 feet thick. "The Big George is an exploratory play located west of the Wyodak fairway," notes Dea. Barrett has drilled 33 wells in it to date, and plans 100 additional Big George wells this year. "The Powder River coalbed play is a wide-open resource, and we think it's the most exciting play to emerge in the Rockies in the last 30 to 40 years," says Dea. "It's a classic company-builder project, and we believe this play alone has the potential to double our reserve base over the next several years." Preston, Reynolds & Co. Inc., a Denver-based private firm, also sees the Powder River play as a company maker. "All of our production is coalbed methane and that's the sole focus of our business," says president Eric Szaloczi. Operating as The Redstone Cos., the firm was an early entrant into coalbed production, starting in the play in 1994. "It's now a $500 world, but when we started it was a $5 world," he notes. The company expended great effort gathering an extensive geological and technical database. In addition to incorporating all the public sources of information on oil and gas wells, it developed relationships with coal companies and gained access to their stores of private data. It also added water well data from Wyoming and southern Montana. "We ended up with thousands of wells in our database," says Szaloczi. "We wanted to really understand the play." The company isolated three particular areas where it determined the coals were thickest. "We weren't looking for acreage as much as for tons of coal per acre. That's what governs the reservoir, and that's what we went after," he says. "We surgically leased about 250,000 acres where we needed to be, and we tried to high-grade our acreage from the beginning," says Michael Batzer, managing director. The leases are a mixture of state, federal and fee lands, ranging from about 30% federal to 45% federal acreage in the various areas. Preston, Reynolds developed three project areas. Its first and smallest project, Rough Draw in Campbell County, lies in the northern portion of the Wyodak fairway. "We've drilled 300 wells in Rough Draw, and about 200 are producing," says Szaloczi. This project has a gathering system and pipeline in place, and is the most mature of the company's ventures. For 2000, Preston, Reynolds will drill between 100 and 200 additional wells at Rough Draw. The company's second project, Tongue River, lies in Big Horn County, Montana, with a portion slipping over into Sheridan County, Wyoming. Tongue River was put on line recently; about 100 of 150 wells are already producing. "We're the only company actively developing coalbed methane production in Montana," notes Szaloczi. The company's newest and most exploratory area is its Lake DeSmet project, located in Johnson County near Buffalo, Wyoming. "This area features the thickest known coal body in the United States," says Szaloczi. Lake DeSmet is mainly comprised of fee leasehold. Preston, Reynolds dealt with three major entities to acquire the acreage: Texaco, the Lake DeSmet Energy Co., and the Peabody Coal Co. "We worked with Peabody for three years to get a deal done. Peabody finally decided it wanted to participate in the development, so we formed a joint venture with it that we operate, called Wagonbox Partners," says Szaloczi. Preston, Reynolds has drilled 50 wells on the project so far, but has not yet installed gathering lines or pipelines. For 2000, the company plans 500 wells in the two western projects; it has an inventory of 8,000 drilling locations. Its gross operated production is about 40 million cubic feet per day, and by the close of this year it expects to add an additional 40 million per day. Batzer notes that Preston, Reynolds is constantly experimenting with drilling and completion technology and the design of gathering systems for the coalbed wells. The company stimulates its wellbores; it also has designed an electronic system to control the downhole water-well pumps that it uses. "We also have installed the hard wiring to enable us to control our wells from a central field point. We can monitor our wells on a real-time basis, and that's important to us," he says. Too, it will drill its first horizontal wells in the coals this spring at its Lake DeSmet project. "We're trying to develop more effective wellbores and reduce the number of wells that we need. If these work, they will cut down the impact on the land as well as the capital costs," says Szaloczi. "Coalbed methane is a low-cost gas resource, but it requires many wells and a huge web of gathering systems to extract it. The economics are very much affected by the effectiveness of the wellbores," he says. "As we advance our technology, our well performance is getting much better." Indeed, for most all of Wyoming's gas plays, that's the story in a nutshell.

Recommended Reading

E&P Earnings Season Proves Up Stronger Efficiencies, Profits

2024-04-04 - The 2024 outlook for E&Ps largely surprises to the upside with conservative budgets and steady volumes.

EQT Declares Quarterly Dividend

2024-04-18 - EQT Corp.’s dividend is payable June 1 to shareholders of record by May 8.

Sunoco’s $7B Acquisition of NuStar Evades Further FTC Scrutiny

2024-04-09 - The waiting period under the Hart-Scott-Rodino Antitrust Improvements Act for Sunoco’s pending acquisition of NuStar Energy has expired, bringing the deal one step closer to completion.

Magnolia Appoints David Khani to Board

2024-02-08 - David Khani’s appointment to Magnolia Oil & Gas’ board as an independent director brings the board’s size to eight members.

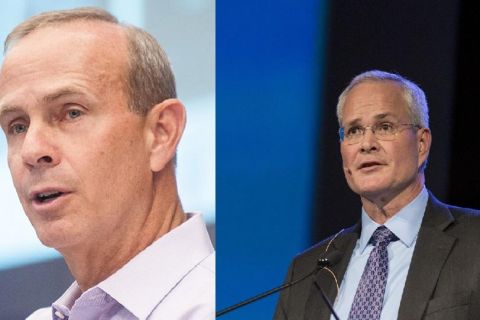

Exxon, Chevron Tapping Permian for Output Growth in ‘24

2024-02-02 - Exxon Mobil and Chevron plan to tap West Texas and New Mexico for oil and gas production growth in 2024, the U.S. majors reported in their latest earnings.